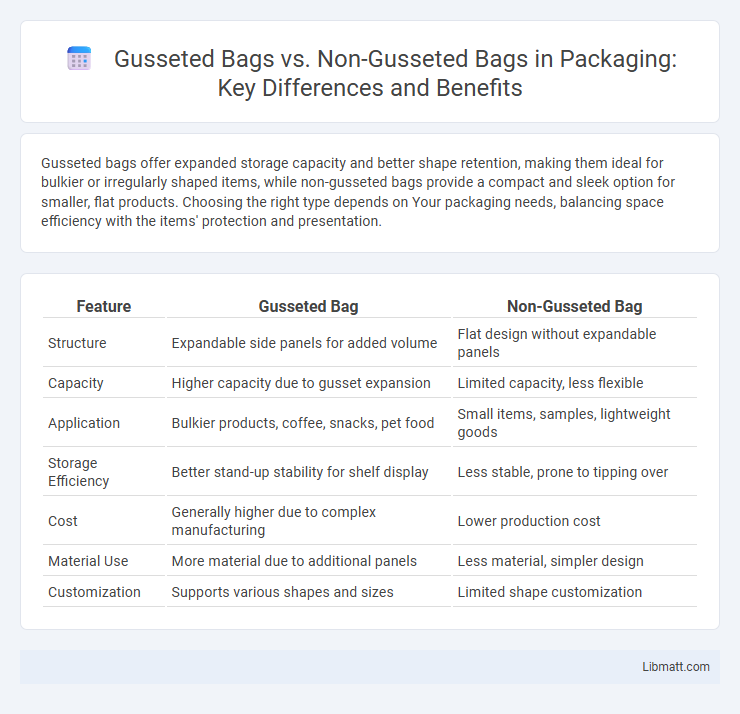

Gusseted bags offer expanded storage capacity and better shape retention, making them ideal for bulkier or irregularly shaped items, while non-gusseted bags provide a compact and sleek option for smaller, flat products. Choosing the right type depends on Your packaging needs, balancing space efficiency with the items' protection and presentation.

Table of Comparison

| Feature | Gusseted Bag | Non-Gusseted Bag |

|---|---|---|

| Structure | Expandable side panels for added volume | Flat design without expandable panels |

| Capacity | Higher capacity due to gusset expansion | Limited capacity, less flexible |

| Application | Bulkier products, coffee, snacks, pet food | Small items, samples, lightweight goods |

| Storage Efficiency | Better stand-up stability for shelf display | Less stable, prone to tipping over |

| Cost | Generally higher due to complex manufacturing | Lower production cost |

| Material Use | More material due to additional panels | Less material, simpler design |

| Customization | Supports various shapes and sizes | Limited shape customization |

Introduction to Gusseted and Non-Gusseted Bags

Gusseted bags feature expandable side or bottom panels that increase storage capacity and allow the bag to stand upright, making them ideal for bulkier items and enhanced display. Non-gusseted bags, lacking these expandable sections, provide a simpler, flat design suited for lighter, less voluminous contents and easier stacking. Choosing between gusseted and non-gusseted bags depends on the product's size, weight, and presentation requirements.

Key Differences Between Gusseted and Non-Gusseted Bags

Gusseted bags feature expandable side or bottom panels that provide extra capacity and structure, allowing the bag to hold bulkier or irregularly shaped items with ease. Non-gusseted bags lack these expandable sections, making them more compact but limiting their volume and flexibility for storing larger contents. Your choice between these bag types depends on whether you need enhanced space and stability, which gusseted bags offer, or a sleeker design that non-gusseted bags provide.

Material Choices for Each Bag Type

Gusseted bags often utilize flexible materials like kraft paper, polyethylene, and laminated films to accommodate expanded volume and maintain shape. Non-gusseted bags typically use thinner materials such as single-layer plastic or paper, suited for flat, lightweight packaging. Your choice of material influences durability, capacity, and packaging aesthetics for both bag types.

Structural Advantages of Gusseted Bags

Gusseted bags offer enhanced structural stability due to their expandable side panels, allowing for greater volume capacity and better accommodation of bulky or oddly shaped items. The design distributes weight more evenly, reducing strain on seams and minimizing the risk of tearing during handling and transport. This structural advantage makes gusseted bags ideal for packaging products that require durability and efficient space utilization compared to non-gusseted bags.

Space Efficiency: Storage and Packing Comparison

Gusseted bags offer superior space efficiency by expanding their width, allowing more items to be packed securely and reducing wasted space compared to non-gusseted bags. Non-gusseted bags have a flat design that limits their storage capacity, often causing irregular shapes and inefficient packing. The added expansion in gusseted bags enhances stacking and organization, making them ideal for optimized storage solutions.

Visual Appeal and Branding Opportunities

Gusseted bags provide enhanced visual appeal with expanded surface areas that accommodate larger, more eye-catching designs, boosting your branding impact. Non-gusseted bags, while sleek and compact, offer limited space for graphics and logos, potentially reducing brand visibility. Choosing gusseted bags allows your packaging to stand out on shelves and convey a stronger brand message through bold colors and detailed artwork.

Cost Considerations and Budget Impact

Gusseted bags generally incur higher production costs due to additional material and manufacturing complexity, impacting overall packaging budgets significantly in large volume orders. Non-gusseted bags offer cost savings by using less material and simpler fabrication processes, making them ideal for budget-conscious projects with standard packaging needs. Selecting between gusseted and non-gusseted bags requires balancing improved product protection and display benefits against tighter cost constraints to optimize budget allocation.

Suitability for Different Products and Industries

Gusseted bags offer expanded capacity and flexibility, making them ideal for bulky or irregularly shaped products like coffee beans, pet food, and hardware, commonly used in food packaging and manufacturing industries. Non-gusseted bags provide a streamlined, compact design suited for smaller, lighter items such as cosmetics, pharmaceuticals, and retail goods where space efficiency and easy stacking are priorities. Choosing between gusseted and non-gusseted bags depends on your product's size, volume, and industry-specific packaging requirements.

Environmental Impact and Sustainability Factors

Gusseted bags, with their expandable sides, maximize storage efficiency, reducing the need for excess packaging material and lowering overall waste. Non-gusseted bags, while simpler in design, often require additional external packaging to accommodate bulkier items, leading to higher material consumption and environmental footprint. Choosing gusseted bags can enhance Your sustainability efforts by minimizing plastic usage and promoting eco-friendly packaging solutions.

Choosing the Right Bag for Your Application

Selecting between gusseted and non-gusseted bags depends on your storage and packaging needs, as gusseted bags offer expanded capacity and better shape retention ideal for bulkier items. Non-gusseted bags are more compact and suitable for smaller, flat items where space efficiency and ease of stacking are priorities. Understanding your product dimensions and handling requirements ensures you choose the right bag, enhancing protection and presentation for your application.

Gusseted bag vs non-gusseted bag Infographic

libmatt.com

libmatt.com