Cold seal wraps use pressure-sensitive adhesives activated by touch, providing a smooth, mess-free finish ideal for delicate packaging, while hot melt wraps rely on heat-activated adhesives that create a strong, durable seal perfect for heavy-duty products. Your choice depends on the packaging requirements, such as speed of application, product sensitivity, and environmental conditions.

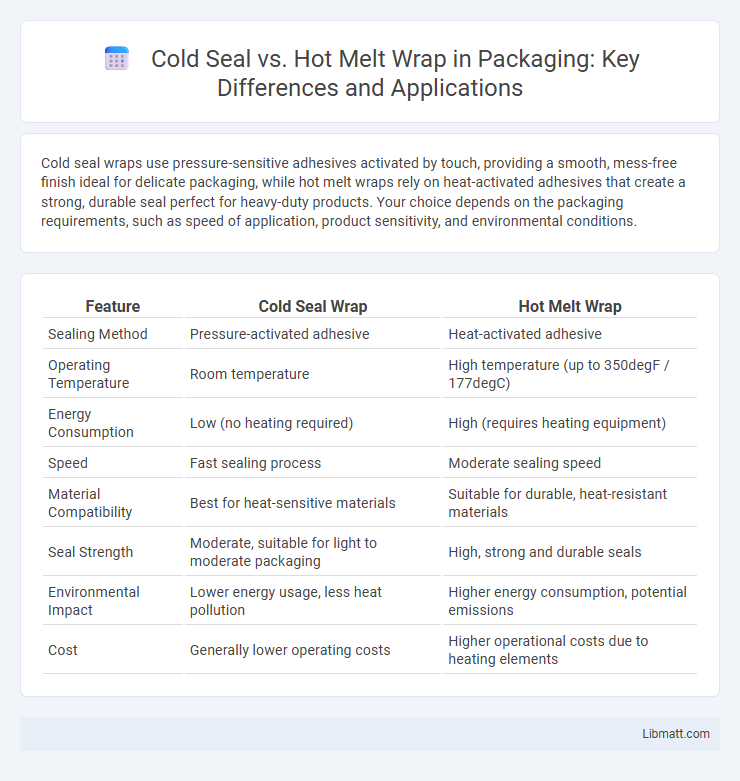

Table of Comparison

| Feature | Cold Seal Wrap | Hot Melt Wrap |

|---|---|---|

| Sealing Method | Pressure-activated adhesive | Heat-activated adhesive |

| Operating Temperature | Room temperature | High temperature (up to 350degF / 177degC) |

| Energy Consumption | Low (no heating required) | High (requires heating equipment) |

| Speed | Fast sealing process | Moderate sealing speed |

| Material Compatibility | Best for heat-sensitive materials | Suitable for durable, heat-resistant materials |

| Seal Strength | Moderate, suitable for light to moderate packaging | High, strong and durable seals |

| Environmental Impact | Lower energy usage, less heat pollution | Higher energy consumption, potential emissions |

| Cost | Generally lower operating costs | Higher operational costs due to heating elements |

Introduction to Cold Seal and Hot Melt Wrap

Cold seal wrap uses pressure-sensitive adhesive activated by pressure without heat, ideal for heat-sensitive products and energy-efficient packaging. Hot melt wrap involves thermoplastic adhesive heated to a molten state, providing strong, durable seals for various packaging applications. Both methods offer distinct advantages depending on product requirements, sealing speed, and packaging material compatibility.

Key Differences Between Cold Seal and Hot Melt

Cold seal wraps activate through pressure and do not require heat, making them ideal for heat-sensitive products, while hot melt wraps use heat to bond materials quickly and provide stronger seals. Cold seal films often provide safer packaging for food items sensitive to temperature, whereas hot melt wraps offer superior durability and resistance to punctures or tears. Your choice between cold seal and hot melt should consider product sensitivity, packaging speed requirements, and desired seal strength.

How Cold Seal Wrap Works

Cold seal wrap works by using pressure-sensitive adhesives that bond upon contact without the need for heat, preserving the integrity of heat-sensitive products like chocolates and confectionery. This method ensures quick, secure sealing by activating the adhesive through simple pressure, which maintains product freshness and reduces energy consumption in packaging operations. Your packaging process benefits from increased efficiency and product protection with cold seal wrap technology.

How Hot Melt Wrap Operates

Hot melt wrap operates by applying a thermoplastic adhesive that melts when heated, allowing it to bond securely to the packaging surface as it cools and solidifies. This process ensures a strong, durable seal that is resistant to moisture and temperature fluctuations, making it ideal for high-speed production lines. You can rely on hot melt wrap for efficient, airtight packaging that enhances product protection and shelf life.

Material Compatibility for Cold Seal vs Hot Melt

Cold seal wraps are ideal for heat-sensitive materials such as chocolates and fresh produce, as their adhesive activates under pressure without requiring heat, preserving product integrity. Hot melt wraps use thermoplastic adhesives that require heat to bond, offering strong seals suitable for a wide range of packaging materials, including plastics and foils. Your choice depends on the material's heat tolerance and the desired sealing strength for optimal packaging performance.

Speed and Efficiency in Packaging Processes

Cold seal wraps offer faster application speeds due to their instant adhesion at room temperature, reducing packaging cycle times and energy consumption. Hot melt wraps require heating, which slows down the process and increases energy usage but provide stronger bonds for heavy or irregularly shaped products. Packaging lines prioritizing speed and efficiency often favor cold seal technology for quicker throughput and lower operational costs.

Cost Comparison: Cold Seal vs Hot Melt

Cold seal wraps generally offer lower initial installation costs compared to hot melt wraps due to simpler machinery and reduced energy consumption. Hot melt wraps, while more expensive upfront, provide stronger seals that may reduce product losses and packaging defects, potentially lowering long-term expenses. Over time, the total cost comparison depends on production volume, product sensitivity, and desired seal durability.

Application Suitability and Industry Uses

Cold seal wraps, ideal for heat-sensitive products, are widely used in the food industry for packaging chocolates, snacks, and pharmaceuticals, ensuring product integrity without heat exposure. Hot melt wraps provide stronger seals suitable for heavy-duty packaging in industries like automotive, electronics, and consumer goods, where durability and moisture resistance are critical. Choosing between cold seal and hot melt wraps depends on product sensitivity, packaging speed requirements, and industry-specific standards.

Environmental Impact and Sustainability

Cold seal wraps use water-based adhesives that emit fewer volatile organic compounds (VOCs), making them more environmentally friendly compared to hot melt wraps, which rely on synthetic, petroleum-based adhesives. Your choice of cold seal packaging supports sustainability by facilitating easier recycling and reducing carbon footprints associated with adhesive production and application. Hot melt seals, while providing strong bonding, typically contribute to higher energy consumption and more challenging recycling processes due to their chemical composition.

Choosing the Right Wrap for Your Packaging Needs

Choosing the right wrap for your packaging needs depends on the product type and sealing requirements. Cold seal wraps provide a moisture-activated adhesive ideal for heat-sensitive products, while hot melt wraps use heat to create strong, durable seals suitable for high-speed production lines. Your choice influences packaging efficiency, product protection, and overall presentation quality.

Cold seal vs hot melt wrap Infographic

libmatt.com

libmatt.com