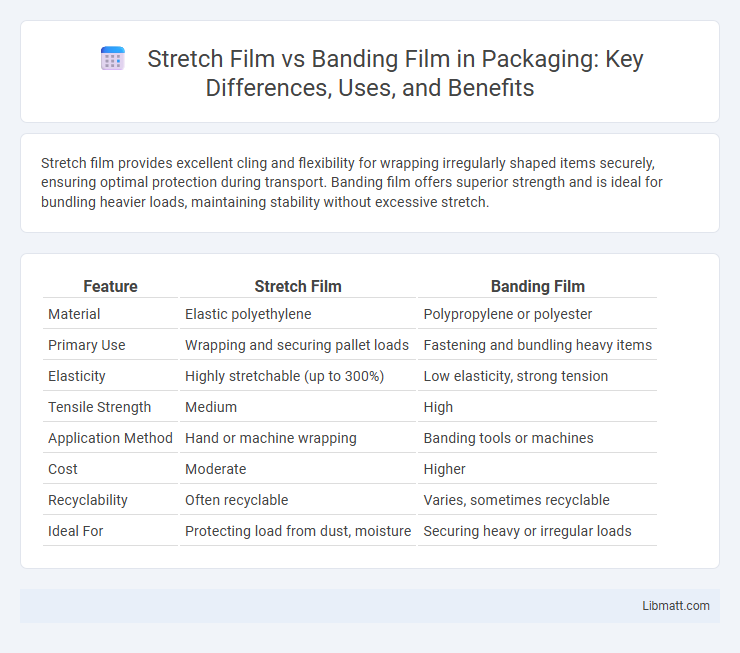

Stretch film provides excellent cling and flexibility for wrapping irregularly shaped items securely, ensuring optimal protection during transport. Banding film offers superior strength and is ideal for bundling heavier loads, maintaining stability without excessive stretch.

Table of Comparison

| Feature | Stretch Film | Banding Film |

|---|---|---|

| Material | Elastic polyethylene | Polypropylene or polyester |

| Primary Use | Wrapping and securing pallet loads | Fastening and bundling heavy items |

| Elasticity | Highly stretchable (up to 300%) | Low elasticity, strong tension |

| Tensile Strength | Medium | High |

| Application Method | Hand or machine wrapping | Banding tools or machines |

| Cost | Moderate | Higher |

| Recyclability | Often recyclable | Varies, sometimes recyclable |

| Ideal For | Protecting load from dust, moisture | Securing heavy or irregular loads |

Introduction to Stretch Film and Banding Film

Stretch film, a highly elastic plastic wrap, is designed for secure pallet wrapping, enhancing load stability and protection during transportation. Banding film, a narrow, durable plastic strip, is specifically engineered for bundling and securing smaller items or packages. Both films serve critical roles in packaging by improving product safety and facilitating efficient handling.

Key Differences Between Stretch Film and Banding Film

Stretch film offers high elasticity and clings tightly to products for secure pallet wrapping, while banding film has lower stretch but provides strong tensile strength for bundling items together. Stretch film is typically used for wrapping irregularly shaped loads, ensuring stability and protection during transport, whereas banding film is ideal for straight, uniform bundles requiring firm restraint without slipping. The primary differences lie in their elasticity, application methods, and the types of loads they are designed to secure.

Common Uses of Stretch Film

Stretch film is primarily used for securing pallet loads, protecting goods during transportation, and bundling smaller items together in warehouses and logistics. Its elasticity and cling properties make it ideal for stabilizing products without damaging sensitive surfaces. Industries such as food packaging, manufacturing, and retail heavily rely on stretch film for efficient storage and shipment.

Common Applications of Banding Film

Banding film is commonly used for bundling smaller items together, securing products on pallets, and stabilizing irregularly shaped loads during transportation. It provides a tight, consistent hold, making it ideal for packaging cardboard boxes, paper products, and lightweight goods. Your choice of banding film enhances load stability and ensures safer handling in logistics and warehousing operations.

Material Composition and Durability

Stretch film is typically made from linear low-density polyethylene (LLDPE), providing excellent elasticity and cling for secure wrapping, while banding film often consists of polypropylene (PP) or polyester, designed for higher tensile strength and resistance to tearing. The durability of stretch film allows it to absorb impacts and conform tightly around irregular shapes, making it ideal for pallet stabilization, whereas banding film offers superior resistance to punctures and UV exposure, suitable for long-term outdoor use. Your choice between these films should consider the required application environment and load protection needs to ensure optimal performance.

Cost Comparison: Stretch Film vs Banding Film

Stretch film generally offers a lower cost per unit of coverage compared to banding film due to its ability to wrap and secure items in fewer layers, reducing material usage. Banding film, while typically more expensive per meter, provides greater tensile strength and is ideal for bundling heavy or irregularly shaped loads, which can justify the higher cost in specific industrial applications. Overall, the choice between stretch film and banding film depends on balancing the cost efficiency of material usage against the strength requirements of the packaging task.

Performance in Packaging and Shipping

Stretch film offers superior flexibility and cling, securely wrapping irregularly shaped items to prevent shifting during shipping, while banding film provides high tensile strength for bundling and stabilizing heavy loads. Your choice depends on whether you need tight load stabilization with stretch film's elasticity or the rigid hold of banding film to prevent product movement. Both films enhance packaging performance by minimizing damage and improving load integrity throughout transportation.

Environmental Impact and Sustainability

Stretch film, typically made from low-density polyethylene (LDPE), often poses environmental challenges due to its low biodegradability and the difficulty of recycling contaminated film, leading to waste accumulation in landfills. Banding film, usually crafted from polypropylene or polyester, generally offers better recyclability and higher strength, which reduces film usage and waste generation during packaging. Choosing banding film over stretch film can enhance sustainability by minimizing raw material consumption and improving the efficiency of waste recovery processes.

Choosing the Right Film for Your Business

Stretch film offers superior elasticity and clings tightly to irregularly shaped products, making it ideal for securing pallets and bundling diverse items efficiently. Banding film provides high tensile strength with minimal stretch, perfect for stabilizing heavy loads and ensuring safe transportation without shifting. Selecting between stretch film or banding film depends on load type, weight, and handling requirements to optimize protection and cost-effectiveness in your supply chain.

Conclusion: Which Film Suits Your Needs?

Stretch film offers superior flexibility and clings tightly to irregularly shaped items, making it ideal for securing pallets and protecting goods from dust and moisture. Banding film provides high tensile strength with less stretch, perfect for bundling heavy or uniform loads without causing damage. To determine which film suits your needs, consider the load type and handling requirements, ensuring you select the option that balances protection and efficiency for your specific application.

Stretch film vs banding film Infographic

libmatt.com

libmatt.com