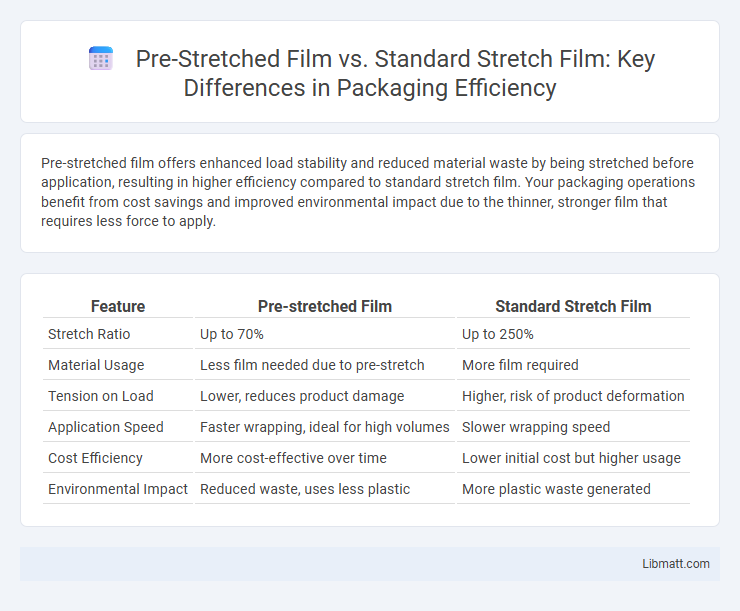

Pre-stretched film offers enhanced load stability and reduced material waste by being stretched before application, resulting in higher efficiency compared to standard stretch film. Your packaging operations benefit from cost savings and improved environmental impact due to the thinner, stronger film that requires less force to apply.

Table of Comparison

| Feature | Pre-stretched Film | Standard Stretch Film |

|---|---|---|

| Stretch Ratio | Up to 70% | Up to 250% |

| Material Usage | Less film needed due to pre-stretch | More film required |

| Tension on Load | Lower, reduces product damage | Higher, risk of product deformation |

| Application Speed | Faster wrapping, ideal for high volumes | Slower wrapping speed |

| Cost Efficiency | More cost-effective over time | Lower initial cost but higher usage |

| Environmental Impact | Reduced waste, uses less plastic | More plastic waste generated |

Introduction to Pre-Stretched Film and Standard Stretch Film

Pre-stretched film is a type of stretch film that has been mechanically stretched before application, offering superior load stability and reduced material waste compared to standard stretch film. Standard stretch film requires more effort to stretch during wrapping, which can lead to inconsistent tension and higher film consumption. Your choice between these films impacts packaging efficiency, cost-effectiveness, and environmental footprint based on your specific wrapping needs.

Key Differences Between Pre-Stretched and Standard Stretch Film

Pre-stretched film is mechanically stretched during manufacturing, resulting in higher tensile strength and reduced material usage compared to standard stretch film, which is stretched manually during application. Pre-stretched film offers enhanced load stability and greater resistance to punctures and tears, making it more efficient for heavy or irregular loads. Standard stretch film provides versatility and is generally more cost-effective but requires more effort to achieve optimal load containment and may consume more film per pallet.

Material Composition and Manufacturing Process

Pre-stretched film consists of a high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE) blend that undergoes a specialized stretching process during manufacturing, enhancing its tensile strength and elasticity by aligning polymer chains. Standard stretch film is typically made from LLDPE using a blown or cast extrusion process without pre-stretching, resulting in a higher raw material usage and lower initial tensile properties. The pre-stretching technique reduces waste and provides superior load containment efficiency compared to the standard manufacturing process of conventional stretch films.

Strength and Load Stability Comparison

Pre-stretched film offers higher tensile strength and superior load stability compared to standard stretch film due to its uniform thickness and elastic properties. This enhanced strength reduces the risk of film tearing and load shifting during transportation or storage. Choosing pre-stretched film can improve your packaging reliability and minimize material waste while maintaining secure load containment.

Application Techniques and User Friendliness

Pre-stretched film requires less manual effort and tension during application due to its factory-stretched properties, enhancing user friendliness by reducing fatigue and improving wrap speed. Standard stretch film demands more physical strength and precision in stretching to achieve optimal load stability, which can increase the risk of inconsistent tension and material waste. Application techniques for pre-stretched film are more efficient, allowing for faster wrapping cycles and consistent coverage, while standard stretch film often needs multiple passes to secure loads effectively.

Cost Efficiency and Material Savings

Pre-stretched film offers superior cost efficiency by reducing material usage up to 30% compared to standard stretch film, resulting in significant savings on packaging expenses. Its high tensile strength allows for effective load securing with thinner layers, minimizing waste and lowering transportation costs due to decreased weight. Businesses benefit from optimized resource consumption and reduced environmental impact through judicious use of pre-stretched film in wrapping applications.

Environmental Impact and Sustainability

Pre-stretched film uses significantly less raw material than standard stretch film, reducing plastic waste and lowering carbon emissions during production. Its efficient application minimizes energy consumption and decreases the volume of plastic sent to landfills, enhancing your sustainability efforts. Switching to pre-stretched film supports eco-friendly packaging by promoting resource conservation and reducing environmental impact.

Performance in Various Shipping Conditions

Pre-stretched film offers superior uniform tension and reduced material usage, enhancing load stability during transportation across fluctuating temperatures and humidity. Standard stretch film provides strong elasticity, which adapts well to uneven or irregularly shaped cargo but may require more material for comparable hold. Both films perform effectively in diverse shipping conditions, though pre-stretched film maximizes cost-efficiency and consistency in high-volume packing environments.

Suitability for Different Industry Needs

Pre-stretched film offers superior strength and uniform tension, making it ideal for industries requiring efficient pallet stability and reduced material waste, such as logistics and food packaging. Standard stretch film provides greater flexibility and cost-effectiveness, suiting industries with less demanding load containment needs like retail and general warehousing. Selecting between these films depends on factors like load type, stretch requirements, and budget constraints within specific industry applications.

Choosing the Right Stretch Film for Your Business

Pre-stretched film offers enhanced load stability and material savings compared to standard stretch film, making it ideal for businesses seeking cost efficiency and environmental benefits. Standard stretch film provides greater flexibility for manual wrapping and varying load sizes but typically requires more film per pallet, impacting operational costs. Evaluating load type, wrapping method, and budget constraints helps businesses select the most effective stretch film to optimize packaging performance and reduce waste.

Pre-stretched film vs standard stretch film Infographic

libmatt.com

libmatt.com