Anti-static packaging prevents static electricity buildup by dissipating static charges on the surface, protecting sensitive electronic components from electrostatic discharge (ESD). Conductive packaging, on the other hand, provides a low-resistance path that safely grounds static charges, offering a higher level of protection for your electronic devices during handling and transportation.

Table of Comparison

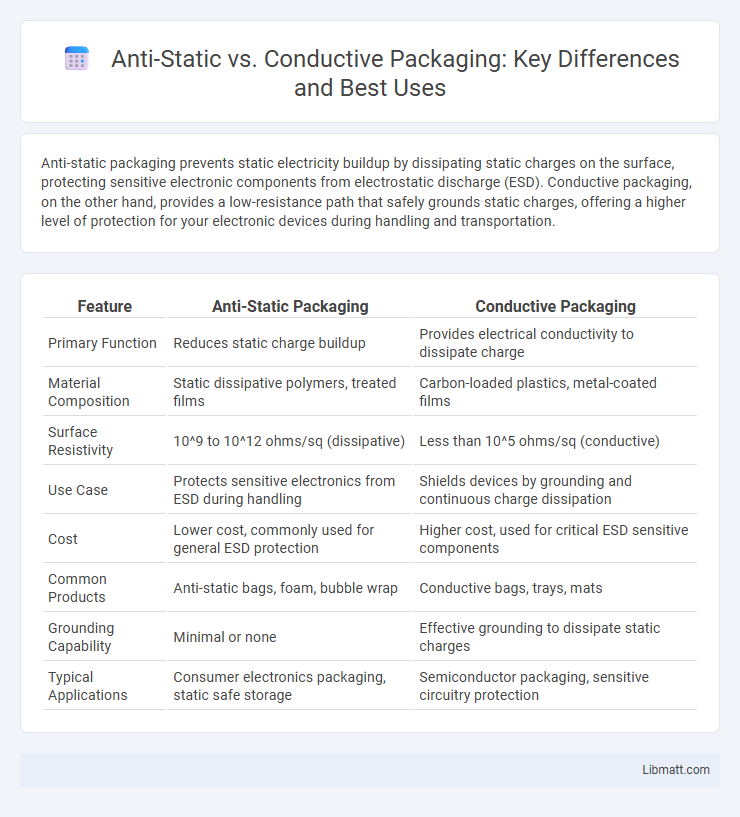

| Feature | Anti-Static Packaging | Conductive Packaging |

|---|---|---|

| Primary Function | Reduces static charge buildup | Provides electrical conductivity to dissipate charge |

| Material Composition | Static dissipative polymers, treated films | Carbon-loaded plastics, metal-coated films |

| Surface Resistivity | 10^9 to 10^12 ohms/sq (dissipative) | Less than 10^5 ohms/sq (conductive) |

| Use Case | Protects sensitive electronics from ESD during handling | Shields devices by grounding and continuous charge dissipation |

| Cost | Lower cost, commonly used for general ESD protection | Higher cost, used for critical ESD sensitive components |

| Common Products | Anti-static bags, foam, bubble wrap | Conductive bags, trays, mats |

| Grounding Capability | Minimal or none | Effective grounding to dissipate static charges |

| Typical Applications | Consumer electronics packaging, static safe storage | Semiconductor packaging, sensitive circuitry protection |

Introduction to Anti-Static and Conductive Packaging

Anti-static packaging materials are designed to prevent the build-up of static electricity, reducing the risk of electrostatic discharge (ESD) damage to sensitive electronic components during handling and transportation. Conductive packaging, on the other hand, offers a path for static electricity to dissipate by incorporating conductive elements, effectively grounding static charges away from protected devices. Both packaging solutions are critical in the electronics industry, with anti-static options providing a controlled environment to minimize static, while conductive packaging actively redirects static charges for enhanced protection.

Understanding Electrostatic Discharge (ESD) Risks

Electrostatic Discharge (ESD) poses significant risks to sensitive electronic components, potentially causing immediate damage or latent failures. Anti-static packaging materials prevent the buildup of static electricity by dissipating charges, reducing the risk of ESD events without providing a conductive path. Conductive packaging, on the other hand, offers a direct path to ground, effectively neutralizing static charges and offering superior protection against ESD in high-risk environments.

What is Anti-Static Packaging?

Anti-static packaging is designed to prevent static electricity buildup on electronic components by dissipating static charges safely to the ground, thereby protecting sensitive devices from electrostatic discharge (ESD) damage. This packaging typically uses materials with controlled electrical resistance that neutralize static without conducting electricity. Common anti-static materials include polyethylene bags treated with static dissipative coatings, ensuring safe transport and storage of semiconductors, circuit boards, and other ESD-sensitive items.

What is Conductive Packaging?

Conductive packaging is designed with materials that allow electrical charges to dissipate safely, preventing static buildup by providing a low-resistance path for electricity. It typically uses carbon-loaded plastics or metalized layers to create a conductive surface that protects sensitive electronic components from electrostatic discharge (ESD). Unlike anti-static packaging, which merely reduces static generation, conductive packaging actively channels electrical charges away, ensuring enhanced protection in high-sensitivity environments.

Key Differences Between Anti-Static and Conductive Packaging

Anti-static packaging prevents the buildup of static electricity by dissipating charges slowly, typically featuring a static dissipative surface with resistance ranging from 10^9 to 10^11 ohms. Conductive packaging offers a much lower surface resistance, usually below 10^5 ohms, allowing rapid charge equalization and providing a direct path to ground. The key difference lies in their electrical properties: anti-static packaging reduces static generation, while conductive packaging enables efficient grounding to protect sensitive electronic components.

Material Composition and Properties

Anti-static packaging materials typically consist of polyethylene or polyester films treated with anti-static agents that reduce static charge buildup by dissipating electrons, while maintaining flexibility and moisture resistance. Conductive packaging is often made from carbon-filled or metalized polymers, such as polyethylene with carbon black or aluminum foil layers, providing a continuous conductive path to effectively shield electronic components from electrostatic discharge (ESD). The key difference lies in the anti-static packaging offering surface resistivity around 10^9 to 10^11 ohms/sq for charge dissipation, whereas conductive packaging exhibits lower resistivity, generally below 10^5 ohms/sq, to ensure effective grounding and ESD protection.

Applications of Anti-Static Packaging

Anti-static packaging is primarily used to protect sensitive electronic components like integrated circuits, semiconductors, and circuit boards from electrostatic discharge (ESD) during storage and transportation. These materials, often made from polyethylene or metalized films, dissipate static charges and prevent damage to your devices. In contrast, conductive packaging offers a higher level of electrical conductivity and is typically applied in environments requiring long-term grounding and shielding against stronger static fields.

Applications of Conductive Packaging

Conductive packaging is widely used in electronics manufacturing to protect sensitive components from electrostatic discharge (ESD) during transport and storage. It is essential for handling integrated circuits, printed circuit boards, and semiconductor devices that require direct grounding to prevent damage. Your choice of conductive packaging ensures safe and efficient delivery of high-value electronic parts in industries such as aerospace, telecommunications, and consumer electronics.

Choosing the Right Packaging for Your Electronics

Selecting the appropriate packaging for electronics depends on the specific electrostatic discharge (ESD) protection needed; anti-static packaging reduces static build-up, making it ideal for components sensitive to static electricity but not requiring full grounding. Conductive packaging provides a continuous path to ground, effectively shielding devices from ESD by dissipating static charges, suitable for highly sensitive electronic components and environments with strict ESD controls. Understanding the electronic device sensitivity, handling environment, and industry standards ensures optimal protection and prevents damage during storage and transportation.

Conclusion: Which Packaging Offers Better Protection?

Anti-static packaging prevents the buildup of static electricity by dissipating charges, making it ideal for protecting sensitive electronic components from electrostatic discharge during handling. Conductive packaging provides a direct path to ground, offering superior protection by shielding devices from static and electromagnetic interference more effectively. Your choice depends on the specific requirements, but conductive packaging generally offers better protection for highly sensitive electronics.

Anti-static packaging vs conductive packaging Infographic

libmatt.com

libmatt.com