Flip-top caps offer quick and convenient access, making them ideal for products you need to open and close frequently, while screw caps provide a more secure and airtight seal suitable for preserving freshness and preventing leaks. Choosing the right closure depends on your product's usage needs and packaging requirements.

Table of Comparison

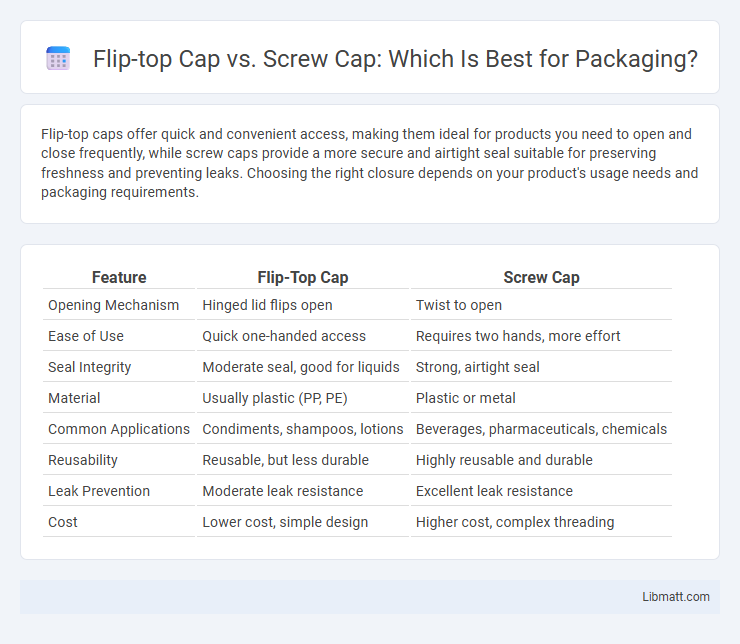

| Feature | Flip-Top Cap | Screw Cap |

|---|---|---|

| Opening Mechanism | Hinged lid flips open | Twist to open |

| Ease of Use | Quick one-handed access | Requires two hands, more effort |

| Seal Integrity | Moderate seal, good for liquids | Strong, airtight seal |

| Material | Usually plastic (PP, PE) | Plastic or metal |

| Common Applications | Condiments, shampoos, lotions | Beverages, pharmaceuticals, chemicals |

| Reusability | Reusable, but less durable | Highly reusable and durable |

| Leak Prevention | Moderate leak resistance | Excellent leak resistance |

| Cost | Lower cost, simple design | Higher cost, complex threading |

Introduction to Flip-Top Caps and Screw Caps

Flip-top caps offer quick, one-handed access and resealability, making them ideal for products like beverages, condiments, and personal care items. Screw caps provide a secure, airtight seal preferred for liquids requiring longer shelf life, such as oils, pharmaceuticals, and chemicals. Your choice between flip-top and screw caps impacts convenience, product preservation, and user experience.

Design and Functionality Differences

Flip-top caps feature a hinged lid that allows quick, one-handed access, ideal for products requiring frequent dispensing like shampoos or lotions. Screw caps provide a secure seal by twisting on and off, ensuring better protection against leaks and contamination, commonly used for liquids like juices or pharmaceuticals. Your choice depends on the ease of use and sealing effectiveness needed for your product packaging.

Ease of Use and Convenience

Flip-top caps offer enhanced ease of use and convenience by allowing quick, one-handed opening and closing without the need to fully unscrew the cap, making them ideal for on-the-go access. Screw caps require twisting to open and close, which can be slower and less practical when you need frequent or rapid access. Your choice between these caps should consider how often and quickly you need to access the container's contents.

Seal Integrity and Leakage Prevention

Flip-top caps provide quick access but may have weaker seal integrity compared to screw caps, which offer a tighter, more secure closure to prevent leakage effectively. Screw caps use threading to create a consistent pressure, minimizing air exposure and ensuring product freshness over time. Choosing the right cap can significantly impact your container's ability to maintain seal integrity and avoid leaks during storage and transport.

Material and Environmental Impact

Flip-top caps are often made from polypropylene (PP), a lightweight plastic that is easily recyclable but may contribute to microplastic pollution if not properly disposed of. Screw caps typically use high-density polyethylene (HDPE), offering a more robust seal and higher recyclability, which can reduce environmental footprints in packaging waste management. Both caps' environmental impacts hinge on material choice, recycling infrastructure, and consumer disposal behavior, with HDPE screw caps generally favored in sustainability assessments for their durability and recyclability.

Cost Comparison and Manufacturing

Flip-top caps generally have a higher manufacturing cost due to their complex hinge design and precision molding requirements, whereas screw caps are simpler and less expensive to produce. The production time for flip-top caps can be longer, impacting overall cost efficiency, while screw caps benefit from faster, more streamlined manufacturing processes. Cost comparisons indicate that screw caps are more economical for large-scale production, whereas flip-top caps may add value through enhanced user convenience despite the higher expense.

Consumer Preferences and User Experience

Flip-top caps offer convenient one-handed operation and quick access, making them popular for on-the-go consumers seeking ease of use. Screw caps provide a secure, airtight seal preferred for products requiring extended freshness and controlled dispensing. Consumer preference often hinges on product type and usage context, with flip-top caps favored for convenience and screw caps for reliability.

Applications Across Industries

Flip-top caps are favored in the personal care and cosmetic industries for their convenience and ease of use, allowing quick dispensing without fully removing the cap. Screw caps dominate in pharmaceuticals and food packaging due to their secure sealing properties that ensure product integrity and prevent contamination. Both cap types cater to specific industry needs, balancing accessibility and protection to optimize product functionality and consumer experience.

Reusability and Recyclability

Flip-top caps offer enhanced convenience for repeated use due to their easy-open design, promoting product preservation and user-friendliness. Screw caps provide a secure seal that is highly reusable, making them ideal for containers requiring tight closure and multiple openings. Both flip-top and screw caps are commonly made from recyclable plastics like polypropylene (PP), contributing to effective recycling processes when properly disposed of.

Choosing the Right Cap for Your Product

Selecting the right cap for your product depends on factors like ease of use, sealing efficiency, and target market preferences. Flip-top caps offer convenience and quick access, ideal for on-the-go products, while screw caps provide a secure, airtight seal suitable for long-term storage and tamper evidence. Understanding your product's packaging needs and consumer expectations ensures optimal performance and satisfaction.

Flip-top cap vs screw cap Infographic

libmatt.com

libmatt.com