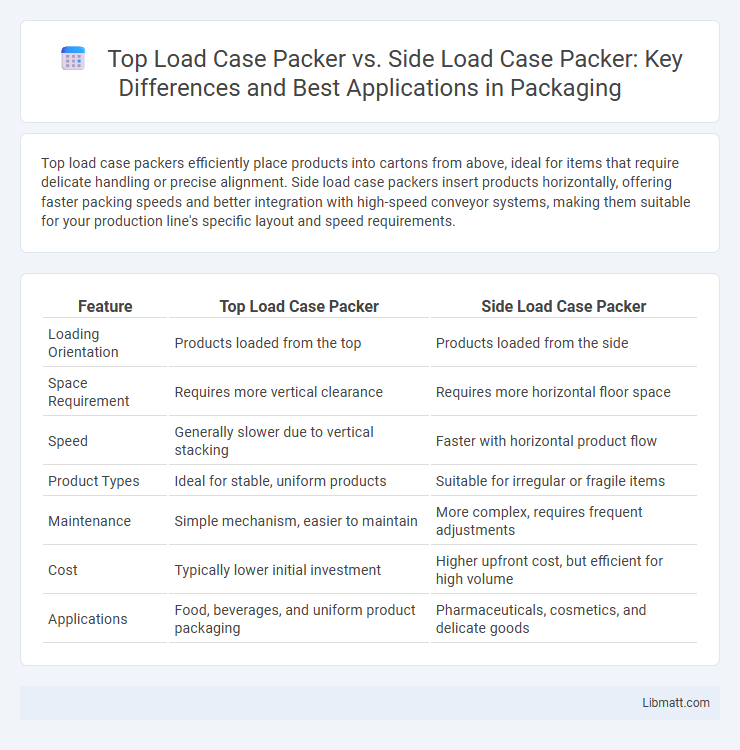

Top load case packers efficiently place products into cartons from above, ideal for items that require delicate handling or precise alignment. Side load case packers insert products horizontally, offering faster packing speeds and better integration with high-speed conveyor systems, making them suitable for your production line's specific layout and speed requirements.

Table of Comparison

| Feature | Top Load Case Packer | Side Load Case Packer |

|---|---|---|

| Loading Orientation | Products loaded from the top | Products loaded from the side |

| Space Requirement | Requires more vertical clearance | Requires more horizontal floor space |

| Speed | Generally slower due to vertical stacking | Faster with horizontal product flow |

| Product Types | Ideal for stable, uniform products | Suitable for irregular or fragile items |

| Maintenance | Simple mechanism, easier to maintain | More complex, requires frequent adjustments |

| Cost | Typically lower initial investment | Higher upfront cost, but efficient for high volume |

| Applications | Food, beverages, and uniform product packaging | Pharmaceuticals, cosmetics, and delicate goods |

Introduction to Case Packers

Top load case packers insert products into the case from the top, allowing for faster loading speeds and easier handling of fragile items. Side load case packers push products horizontally into the case, making them ideal for packaging long or delicate products with minimal product movement. Your choice between these systems should consider product shape, production speed, and space constraints in your packaging line.

What is a Top Load Case Packer?

A Top Load Case Packer is a packaging machine designed to load products vertically from the top into cases or cartons, optimizing space and minimizing product damage during packing. This type of packer is ideal for fragile or irregularly shaped items, as it provides gentle handling and precise placement within the case. Your choice of a top load case packer can enhance packaging efficiency and ensure better product protection compared to side load alternatives.

What is a Side Load Case Packer?

A side load case packer is a packaging machine designed to load products into cases or cartons from the side, optimizing space and handling efficiency for certain production lines. This type of packer is ideal for applications where products require gentle handling or when line layouts demand side entry due to conveyor positioning. Side load case packers improve packaging speed and accommodate a variety of case sizes while maintaining consistent product orientation.

Key Differences Between Top Load and Side Load Case Packers

Top load case packers place products into cases from the top, making them ideal for fragile or delicate items, while side load case packers insert products horizontally, better suited for products requiring precise alignment. Top load packers generally accommodate varying box sizes with easier adjustments, whereas side load packers excel in high-speed, continuous flow packaging environments. Both systems differ significantly in space requirements; top load units typically need more vertical clearance, whereas side load machines optimize floor space with horizontal loading configurations.

Advantages of Top Load Case Packers

Top load case packers offer advantages such as faster changeover times and easier access for machine maintenance, enhancing operational efficiency in your packaging line. They are ideal for fragile or irregularly shaped products because they gently place items into cases from above, reducing damage risk. Their ability to handle a variety of case sizes without extensive adjustments makes them versatile for different production runs.

Advantages of Side Load Case Packers

Side load case packers offer significant advantages including greater versatility for handling varying case sizes and configurations, enabling improved production efficiency in diverse packaging lines. They typically require less factory floor space due to their compact, linear design, optimizing operational layout for better workflow. Enhanced ease of maintenance and reduced mechanical complexity also contribute to lower downtime and operational costs compared to top load case packers.

Applications and Industries for Each Type

Top load case packers are commonly used in the food and beverage, pharmaceutical, and consumer goods industries where products are fragile or require careful handling, such as bottles, jars, and cans. Side load case packers excel in high-speed environments like electronics, automotive parts, and bulk packaging sectors, allowing for efficient loading of uniform or stable products into corrugated cartons. Each type caters to specific packaging needs based on product stability, speed requirements, and industry standards.

Performance and Efficiency Comparison

Top load case packers offer faster cycle speeds and easier product alignment, resulting in higher throughput for uniform, stable products. Side load case packers provide superior flexibility and better handling of delicate or irregularly shaped items, minimizing product damage during packing. Performance efficiency depends on product type and production requirements, with top load machines excelling in speed and side load units excelling in versatility.

Cost Considerations and ROI

Top load case packers often involve higher initial investment costs due to their vertical design and integration complexity but can offer faster cycle times that improve throughput and potential ROI in high-volume operations. Side load case packers typically have lower upfront costs and simpler maintenance requirements, making them suitable for smaller or medium-scale production runs with a quicker break-even point. Your choice should balance initial expenditure against expected production volume and efficiency gains to maximize cost-effectiveness and return on investment.

How to Choose the Right Case Packer for Your Needs

Choosing between a top load case packer and a side load case packer depends on the product type, packaging line speed, and available floor space. Top load case packers are ideal for fragile items and products requiring vertical placement, offering gentle handling and higher throughput for high-speed lines. Side load case packers suit bulkier or irregularly shaped products, optimize space with a horizontal loading mechanism, and provide versatility for various case sizes and packaging configurations.

Top load case packer vs side load case packer Infographic

libmatt.com

libmatt.com