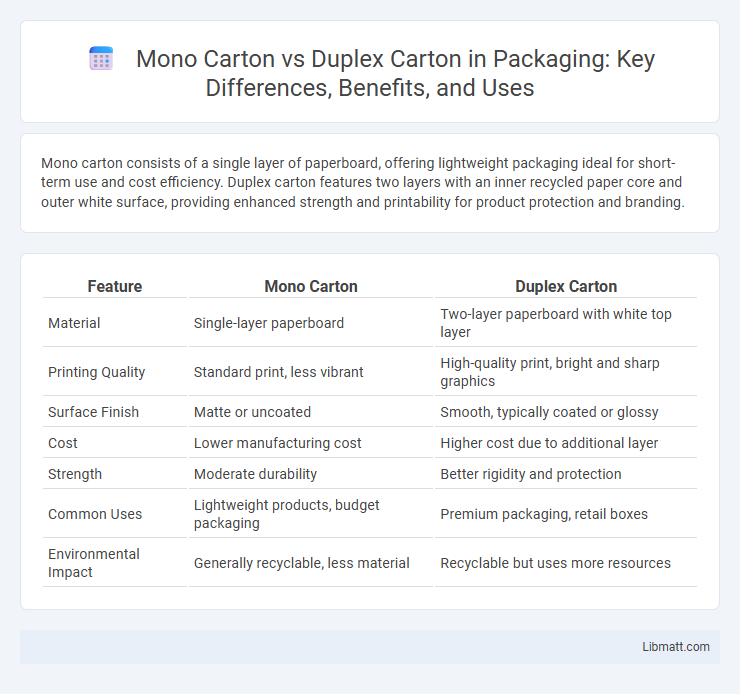

Mono carton consists of a single layer of paperboard, offering lightweight packaging ideal for short-term use and cost efficiency. Duplex carton features two layers with an inner recycled paper core and outer white surface, providing enhanced strength and printability for product protection and branding.

Table of Comparison

| Feature | Mono Carton | Duplex Carton |

|---|---|---|

| Material | Single-layer paperboard | Two-layer paperboard with white top layer |

| Printing Quality | Standard print, less vibrant | High-quality print, bright and sharp graphics |

| Surface Finish | Matte or uncoated | Smooth, typically coated or glossy |

| Cost | Lower manufacturing cost | Higher cost due to additional layer |

| Strength | Moderate durability | Better rigidity and protection |

| Common Uses | Lightweight products, budget packaging | Premium packaging, retail boxes |

| Environmental Impact | Generally recyclable, less material | Recyclable but uses more resources |

Introduction to Mono Carton and Duplex Carton

Mono carton consists of a single layer of paperboard, making it lightweight and cost-effective, ideal for packaging small, lightweight products. Duplex carton features a two-layer construction with a white top layer and a recycled paperboard bottom, offering enhanced stiffness and superior print quality for premium packaging applications. Both cartons are widely used in retail packaging, with duplex cartons preferred for their durability and high-end appearance.

Material Composition: Mono vs Duplex Carton

Mono carton consists of a single layer of uncoated or coated paperboard, making it lightweight and suitable for straightforward packaging needs. Duplex carton features two layers, typically including a white, bleached top layer for printing quality and a lower layer of recycled material for strength and cost efficiency. Choosing between mono and duplex cartons depends on your packaging requirements for durability, printability, and environmental impact.

Structural Differences Between Mono and Duplex Cartons

Mono carton features a single-ply construction primarily made from one type of paperboard, resulting in a uniform thickness and density throughout. Duplex carton consists of two layers--a high-quality, bleached top layer for printing and a heavier, stronger recycled bottom layer--offering enhanced durability and better surface finish. Your choice between these cartons impacts package strength, print clarity, and cost efficiency based on their structural differences.

Printing and Design Capabilities

Mono carton offers a smooth surface ideal for high-quality, vibrant printing, making it suitable for intricate designs and detailed artwork. Duplex carton provides a layered structure with a white, printable top layer and a more textured brown underside, supporting moderate design complexity with cost-effective printing options. Your choice depends on whether you prioritize premium graphic appeal or balanced durability with design versatility.

Packaging Strength and Durability

Mono carton offers moderate packaging strength suitable for lightweight items, while duplex carton provides enhanced durability due to its thicker, dual-layer construction, making it ideal for heavier or fragile products. The superior compression resistance of duplex cartons ensures better protection during shipping and handling. Your choice depends on the weight and fragility of the items being packed, with duplex cartons offering more robust performance for demanding packaging needs.

Cost Comparison: Mono Carton vs Duplex Carton

Mono carton typically costs less than duplex carton due to its single-layer construction, making it ideal for budget-friendly packaging needs. Duplex carton, with its dual-layer design and superior durability, incurs higher production costs but offers enhanced strength and print quality. Choosing between mono and duplex cartons impacts your packaging budget and product protection, depending on your specific requirements.

Sustainability and Environmental Impact

Mono cartons typically consist of a single material layer, making them easier to recycle and more environmentally friendly due to reduced contamination risks during processing. Duplex cartons combine a Kraft paper top layer with recycled paperboard, offering a balance of durability and partial recyclability, though the mixed materials can complicate recycling efforts. Opting for mono cartons supports a circular economy by minimizing waste and enhancing the efficiency of paper reuse, crucial in sustainable packaging practices.

Applications and Industry Usage

Mono carton, made from a single type of paperboard, is widely used in lightweight packaging applications such as food wrappers, cosmetic boxes, and pharmaceutical packaging due to its cost-effectiveness and printability. Duplex carton, composed of two layers including a recycled fiber backing and a virgin fiber outer layer, is preferred in industries requiring enhanced durability and presentation like foodservice packaging, beverage carriers, and retail product packaging. The choice between mono and duplex cartons largely depends on the balance needed between strength, visual appeal, and environmental considerations in various sectors.

Advantages of Mono Cartons

Mono cartons provide superior structural integrity due to their single-material construction, enhancing durability and protection for packaging fragile goods. Their uniform composition simplifies recycling processes, promoting eco-friendly packaging solutions aligned with sustainability goals. Cost-efficiency is another advantage, as mono cartons often require less complex manufacturing techniques, reducing production expenses.

Advantages of Duplex Cartons

Duplex cartons offer superior print quality and durability compared to mono cartons, thanks to their coated surface and sturdy construction that enhance product presentation and protection. Their eco-friendly design often incorporates recycled materials, making them a sustainable choice for packaging. You benefit from duplex cartons' versatility in supporting high-resolution graphics and maintaining structural integrity during shipping and handling.

Mono carton vs duplex carton Infographic

libmatt.com

libmatt.com