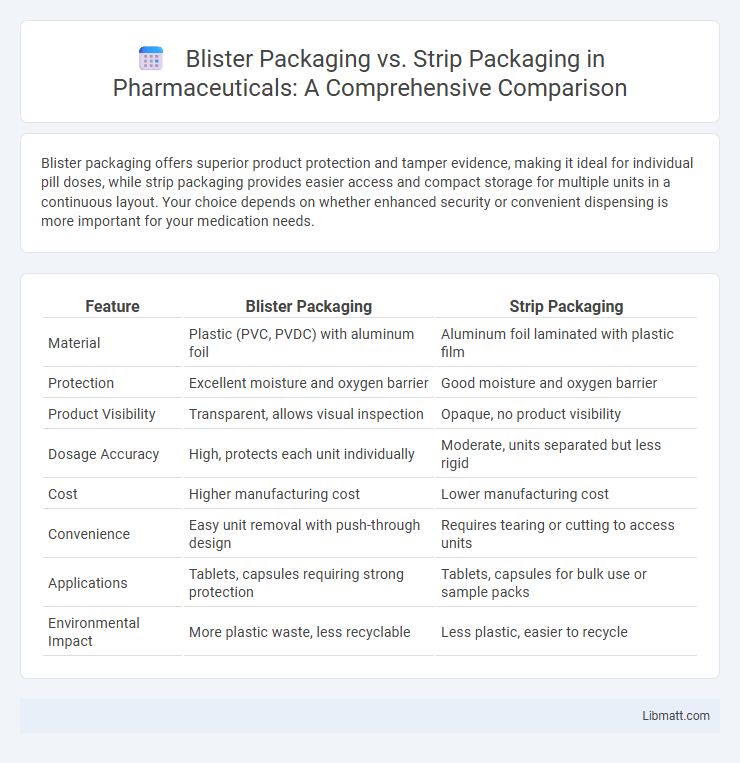

Blister packaging offers superior product protection and tamper evidence, making it ideal for individual pill doses, while strip packaging provides easier access and compact storage for multiple units in a continuous layout. Your choice depends on whether enhanced security or convenient dispensing is more important for your medication needs.

Table of Comparison

| Feature | Blister Packaging | Strip Packaging |

|---|---|---|

| Material | Plastic (PVC, PVDC) with aluminum foil | Aluminum foil laminated with plastic film |

| Protection | Excellent moisture and oxygen barrier | Good moisture and oxygen barrier |

| Product Visibility | Transparent, allows visual inspection | Opaque, no product visibility |

| Dosage Accuracy | High, protects each unit individually | Moderate, units separated but less rigid |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Convenience | Easy unit removal with push-through design | Requires tearing or cutting to access units |

| Applications | Tablets, capsules requiring strong protection | Tablets, capsules for bulk use or sample packs |

| Environmental Impact | More plastic waste, less recyclable | Less plastic, easier to recycle |

Introduction to Blister and Strip Packaging

Blister packaging consists of pre-formed plastic cavities sealed with a backing material, typically used for tablets, capsules, and small consumer goods, offering protection and visibility. Strip packaging uses a laminate film sealed around individual units in a continuous strip, ideal for maintaining product hygiene and ease of dispensing. Understanding the distinct features of blister and strip packaging helps you select the right solution for product safety, convenience, and shelf life.

Key Differences Between Blister and Strip Packaging

Blister packaging features individual compartments sealed with a clear plastic cover, providing enhanced product protection and visibility, while strip packaging consists of multiple units sealed between two flexible layers, offering compactness and ease of dispensing. Blister packs are ideal for fragile items and allow easy identification of contents, whereas strip packs excel in space-saving and cost-effectiveness for uniform products like tablets or capsules. Your choice depends on factors such as product protection needs, shelf appeal, and packaging efficiency.

Materials Used in Blister Packaging

Blister packaging primarily utilizes PVC (polyvinyl chloride), PET (polyethylene terephthalate), and aluminum foil to create durable, transparent cavities that securely hold individual doses or items. These materials offer excellent barrier protection against moisture, oxygen, and contamination, maintaining product integrity and extending shelf life. The choice of materials depends on the product's sensitivity, with PET providing superior clarity and rigidity, while aluminum foil ensures maximum barrier properties.

Materials Used in Strip Packaging

Strip packaging primarily uses plastic and aluminum foil materials, combining these layers to provide excellent moisture and oxygen barriers that preserve product freshness. The plastic layer often includes PVC or PET for flexibility and strength, while the aluminum foil adds durability and protection against light and contaminants. This combination makes strip packaging ideal for pharmaceuticals and small consumer goods, ensuring your products remain secure and intact during storage and transport.

Advantages of Blister Packaging

Blister packaging offers superior product protection by creating a sealed barrier against moisture, contamination, and tampering, ensuring the integrity and safety of pharmaceuticals and consumer goods. Its transparent design allows consumers to easily view the product, enhancing visibility and aiding in product identification. You benefit from blister packaging's convenience and ease of use, as individual doses or items can be accessed without compromising the remaining contents.

Benefits of Strip Packaging

Strip packaging offers precise dosage control by securely enclosing individual tablets or capsules, reducing the risk of contamination and ensuring product integrity. Its compact design facilitates easy portability and efficient space utilization for both consumers and retailers. Enhanced tamper evidence and improved shelf life make strip packaging a preferred choice for pharmaceuticals requiring stringent quality assurance.

Common Applications in the Pharmaceutical Industry

Blister packaging is commonly used for tablets, capsules, and small medical devices, providing individual protection and tamper evidence. Strip packaging suits unit-dose forms such as tablets and capsules, allowing easy dispensing and reducing contamination risks. Both packaging types ensure product integrity and compliance with pharmaceutical regulations.

Cost Comparison: Blister vs Strip Packaging

Blister packaging generally incurs higher material and production costs due to its complex thermoforming process and use of plastic films compared to strip packaging, which utilizes simpler aluminum foil and paper lamination. Strip packaging offers cost efficiency through faster manufacturing speeds and reduced material waste, making it a budget-friendly option for high-volume pharmaceutical products. Your choice between blister and strip packaging should consider not only upfront costs but also factors like product protection and shelf life to ensure overall value.

Environmental Impact and Sustainability

Blister packaging often uses non-recyclable plastic and aluminum layers, contributing to higher environmental waste compared to strip packaging, which typically utilizes recyclable foil and paper materials. Strip packaging reduces material usage and carbon footprint by being lighter and more compact, promoting sustainability through easier disposal and lower resource consumption. Your choice between the two can significantly influence environmental impact, with strip packaging generally offering a greener, more sustainable option.

Choosing the Right Packaging Solution

Selecting the right packaging solution depends on factors such as product protection, patient compliance, and cost efficiency. Blister packaging offers superior protection against moisture and contamination, making it ideal for pharmaceuticals requiring individual doses, while strip packaging provides a flexible, lightweight alternative suitable for high-speed production and easy dosage access. Evaluating product sensitivity, usage environment, and distribution logistics ensures the optimal choice between blister and strip packaging for effective medication delivery.

Blister Packaging vs Strip Packaging Infographic

libmatt.com

libmatt.com