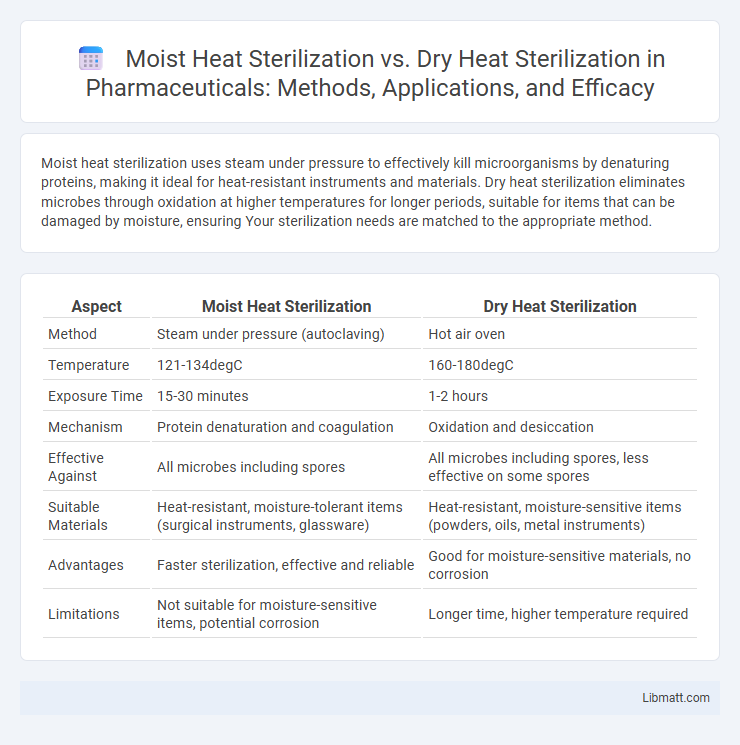

Moist heat sterilization uses steam under pressure to effectively kill microorganisms by denaturing proteins, making it ideal for heat-resistant instruments and materials. Dry heat sterilization eliminates microbes through oxidation at higher temperatures for longer periods, suitable for items that can be damaged by moisture, ensuring Your sterilization needs are matched to the appropriate method.

Table of Comparison

| Aspect | Moist Heat Sterilization | Dry Heat Sterilization |

|---|---|---|

| Method | Steam under pressure (autoclaving) | Hot air oven |

| Temperature | 121-134degC | 160-180degC |

| Exposure Time | 15-30 minutes | 1-2 hours |

| Mechanism | Protein denaturation and coagulation | Oxidation and desiccation |

| Effective Against | All microbes including spores | All microbes including spores, less effective on some spores |

| Suitable Materials | Heat-resistant, moisture-tolerant items (surgical instruments, glassware) | Heat-resistant, moisture-sensitive items (powders, oils, metal instruments) |

| Advantages | Faster sterilization, effective and reliable | Good for moisture-sensitive materials, no corrosion |

| Limitations | Not suitable for moisture-sensitive items, potential corrosion | Longer time, higher temperature required |

Introduction to Heat Sterilization

Heat sterilization employs elevated temperatures to eliminate microorganisms, with moist heat sterilization using steam under pressure to denature proteins effectively, making it faster and more efficient for surgical instruments and lab equipment. Dry heat sterilization relies on hot air at higher temperatures and longer exposure times, ideal for powders, oils, and metal tools that cannot tolerate moisture. Understanding the differences in heat transfer and material compatibility helps you choose the appropriate sterilization method for your specific application needs.

Principles of Moist Heat Sterilization

Moist heat sterilization utilizes saturated steam under pressure to denature proteins and effectively kill microorganisms, including spores. The process typically occurs at 121degC for 15-20 minutes in an autoclave, ensuring rapid and reliable microbial destruction. This method is preferred for heat-resistant, moisture-tolerant surgical instruments and laboratory equipment.

Principles of Dry Heat Sterilization

Dry heat sterilization uses high temperatures ranging from 160degC to 170degC for durations between 2 to 4 hours to kill microorganisms by oxidizing cell components and denaturing proteins. Unlike moist heat sterilization, which relies on steam and pressure to coagulate proteins, dry heat sterilization causes dehydration and enzyme inactivation, making it ideal for materials that cannot be exposed to moisture. You should choose dry heat sterilization for powders, oils, and metal instruments that require thorough sterilization without corrosion or dampness.

Mechanisms of Microbial Destruction

Moist heat sterilization destroys microbial cells primarily through coagulation and denaturation of proteins, effectively inactivating enzymes and structural proteins by using saturated steam under pressure, typically in an autoclave at 121degC for 15-20 minutes. Dry heat sterilization eliminates microbes by oxidative destruction and protein denaturation caused by high temperatures, usually between 160-180degC for 1-2 hours, resulting in the destruction of cell components and dehydration of microbial cells. Both methods achieve sterilization but differ in kinetics and applications due to the distinct physical and chemical mechanisms targeting microbial structures.

Equipment and Methods Used

Moist heat sterilization commonly employs autoclaves that use pressurized saturated steam at temperatures of 121-134degC to achieve rapid and effective microbial destruction. Dry heat sterilization utilizes hot air ovens operating at higher temperatures, typically 160-180degC, for longer durations to oxidize cell components and denature proteins. Your choice between these methods depends on the equipment available and the heat tolerance of the items being sterilized.

Temperature and Time Requirements

Moist heat sterilization typically requires lower temperatures, around 121degC to 134degC, for shorter durations of 15 to 30 minutes due to its steam-based mechanism that penetrates materials effectively. Dry heat sterilization operates at higher temperatures, usually between 160degC and 180degC, but demands longer exposure times ranging from 1 to 2 hours to achieve comparable microbial inactivation. The efficiency of sterilization is influenced by the heat transfer properties of steam in moist heat, versus the slower conduction process in dry heat, impacting both time and temperature parameters.

Applications in Healthcare and Laboratories

Moist heat sterilization, primarily using autoclaves, is widely applied in healthcare and laboratories for sterilizing surgical instruments, culture media, and biohazardous waste due to its efficiency in denaturing proteins and killing microorganisms. Dry heat sterilization is preferred for heat-stable materials such as glassware, metal instruments, powders, and oils, where moisture could cause damage or corrosion. Both methods play crucial roles in infection control and ensuring sterile conditions essential for accurate laboratory results and patient safety.

Advantages of Moist Heat Sterilization

Moist heat sterilization offers superior efficiency by penetrating materials faster and denaturing proteins more effectively, resulting in shorter sterilization cycles compared to dry heat. It is particularly advantageous for heat-sensitive instruments and reduces the risk of damage, preserving the integrity and longevity of your medical tools. This method also provides reliable sterilization at lower temperatures, enhancing safety and energy efficiency in medical and laboratory settings.

Advantages of Dry Heat Sterilization

Dry heat sterilization offers advantages such as effective penetration of materials that are sensitive to moisture, making it ideal for sterilizing powders, oils, and metal instruments without corrosion risks. It provides longer shelf life and prevents rusting, which can compromise the integrity of your tools. The process operates at higher temperatures for extended periods, ensuring thorough elimination of resistant spores and microorganisms.

Key Differences and Comparison

Moist heat sterilization uses steam under pressure, typically at 121degC for 15-20 minutes, efficiently killing microorganisms by denaturing proteins, making it ideal for heat-sensitive medical instruments. Dry heat sterilization requires higher temperatures, usually 160-170degC for 1-2 hours, destroying microbes through oxidation, suited for powders, oils, and metal instruments that might be damaged by moisture. Your choice between these methods depends on the material's heat tolerance, sterilization time, and the risk of corrosion or damage.

Moist heat sterilization vs Dry heat sterilization Infographic

libmatt.com

libmatt.com