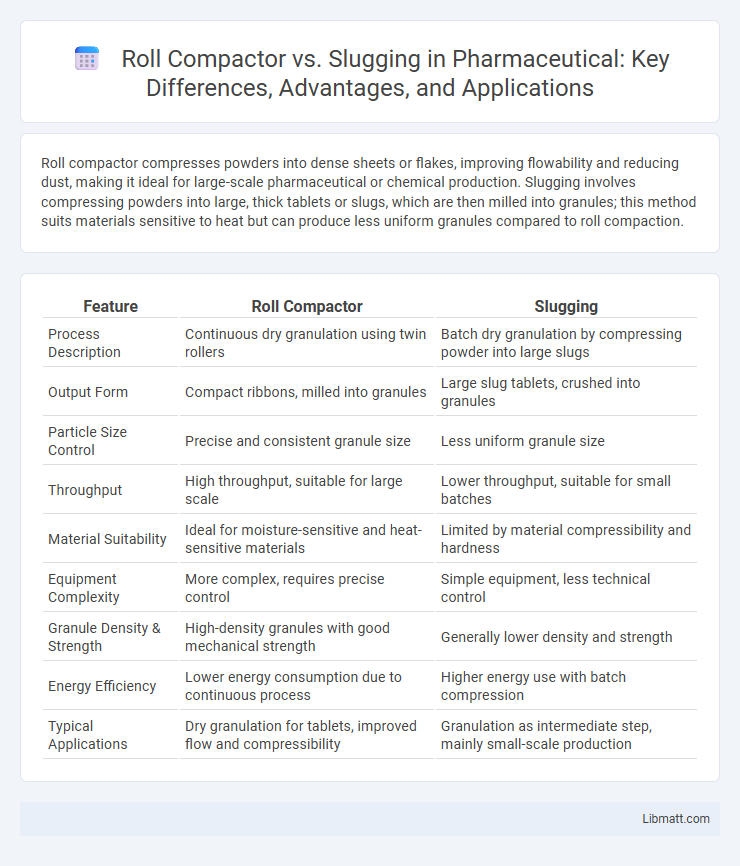

Roll compactor compresses powders into dense sheets or flakes, improving flowability and reducing dust, making it ideal for large-scale pharmaceutical or chemical production. Slugging involves compressing powders into large, thick tablets or slugs, which are then milled into granules; this method suits materials sensitive to heat but can produce less uniform granules compared to roll compaction.

Table of Comparison

| Feature | Roll Compactor | Slugging |

|---|---|---|

| Process Description | Continuous dry granulation using twin rollers | Batch dry granulation by compressing powder into large slugs |

| Output Form | Compact ribbons, milled into granules | Large slug tablets, crushed into granules |

| Particle Size Control | Precise and consistent granule size | Less uniform granule size |

| Throughput | High throughput, suitable for large scale | Lower throughput, suitable for small batches |

| Material Suitability | Ideal for moisture-sensitive and heat-sensitive materials | Limited by material compressibility and hardness |

| Equipment Complexity | More complex, requires precise control | Simple equipment, less technical control |

| Granule Density & Strength | High-density granules with good mechanical strength | Generally lower density and strength |

| Energy Efficiency | Lower energy consumption due to continuous process | Higher energy use with batch compression |

| Typical Applications | Dry granulation for tablets, improved flow and compressibility | Granulation as intermediate step, mainly small-scale production |

Introduction to Dry Granulation: Roll Compactor vs Slugging

Dry granulation techniques, including roll compaction and slugging, play a critical role in pharmaceutical manufacturing by improving powder flow and compressibility without using moisture. Roll compaction utilizes rollers to produce a continuous ribbon or sheet of compacted material, offering consistent particle size and density suitable for large-scale production. Slugging involves compressing powder into large tablets or slugs, which are then milled into granules, a process often preferred for smaller batches but less uniform compared to roll compaction.

Understanding Roll Compaction: Principles and Process

Roll compaction involves compressing powders between two counter-rotating rolls to form ribbons or flakes, which are then milled into granules, enhancing flowability and compressibility. This dry granulation technique preserves material integrity by avoiding heat and moisture exposure, making it ideal for moisture-sensitive pharmaceuticals. The process's uniform pressure distribution ensures consistent particle density, optimizing tablet formulation and manufacturing efficiency.

Slugging Method Explained: Step-by-Step Overview

The slugging method involves compressing powder into large, dense tablets known as slugs, which are later milled into granules for improved flow and compaction. This step-by-step process begins with powder blending, followed by compression into slugs using a tablet press, then milling the slugs to desired granule size before final compression into tablets. You can achieve better control over density and reduce dust by understanding whether the slugging method or roll compactor technology suits your granular production requirements.

Key Differences Between Roll Compactor and Slugging

Roll compactor and slugging differ primarily in their compaction mechanisms; roll compactors use rotating rollers to compress powder into ribbons, enabling continuous and uniform densification, whereas slugging compresses powder in a mold to form large, irregular slugs through batch processing. Roll compaction offers higher throughput and better particle size distribution control, while slugging is often less efficient and produces inconsistent slug sizes. Material flowability and sensitivity to heat also vary significantly, as roll compactors handle delicate substances with minimal heat generation compared to the localized stress in slugging.

Advantages of Roll Compaction in Pharmaceutical Manufacturing

Roll compaction offers superior control over bulk density and particle size distribution, enhancing blend uniformity in pharmaceutical manufacturing. It minimizes dust generation and improves flowability, which reduces material loss and improves process efficiency compared to slugging. The continuous nature of roll compaction supports higher throughput and consistent product quality in large-scale production.

Benefits and Limitations of Slugging Technique

The slugging technique offers the benefit of producing more uniform and dense granules, which enhances the flowability and compressibility of powders in pharmaceutical and industrial processes. However, slugging is limited by its slower processing time, higher energy consumption, and the requirement for large-scale equipment compared to other granulation methods. You should consider these factors when choosing slugging for your formulation to ensure optimal production efficiency and product quality.

Material Suitability: Which Method Performs Better?

Roll compactors excel in processing cohesive powders with good flow properties, ensuring uniform granule density and size distribution ideal for pharmaceutical and chemical industries. Slugging suits materials with poor compressibility and moisture sensitivity, effectively producing larger granules by compressing powders into slugs for subsequent milling. Material suitability depends on powder characteristics, with roll compactors favored for continuous, high-throughput applications, while slugging is preferred for batch processing of difficult powders.

Equipment and Operational Considerations

Roll compactors use two counter-rotating rolls to compress powders into ribbons, offering continuous operation and high throughput suitable for large-scale production. Slugging employs a single heavy-duty tablet press to compress powders into large, dense slugs, requiring batch processing and more frequent downtime for slug ejection. Equipment choice depends on factors like material flowability, desired density, production scale, and operational efficiency.

Quality Control and Product Consistency

Roll compactors provide superior quality control and product consistency by applying uniform pressure, resulting in consistent granule density and size distribution. Slugging often produces irregularly shaped and sized tablets, which can lead to variability in final product quality. Your manufacturing process benefits from roll compaction when aiming for uniform granule flow and predictable tablet compression outcomes.

Choosing the Right Granulation Method: Factors to Consider

Choosing the right granulation method depends on factors like material properties, desired particle size, and production scale, with roll compactors offering precise density control and slugging suited for coarse granules. Moisture content and compressibility significantly influence performance; roll compaction typically handles low-moisture formulations better, while slugging requires careful moisture adjustment to avoid capping. Understanding your formulation's flowability and downstream processing needs ensures optimal selection between roll compactor and slugging to enhance product uniformity and efficiency.

Roll compactor vs slugging Infographic

libmatt.com

libmatt.com