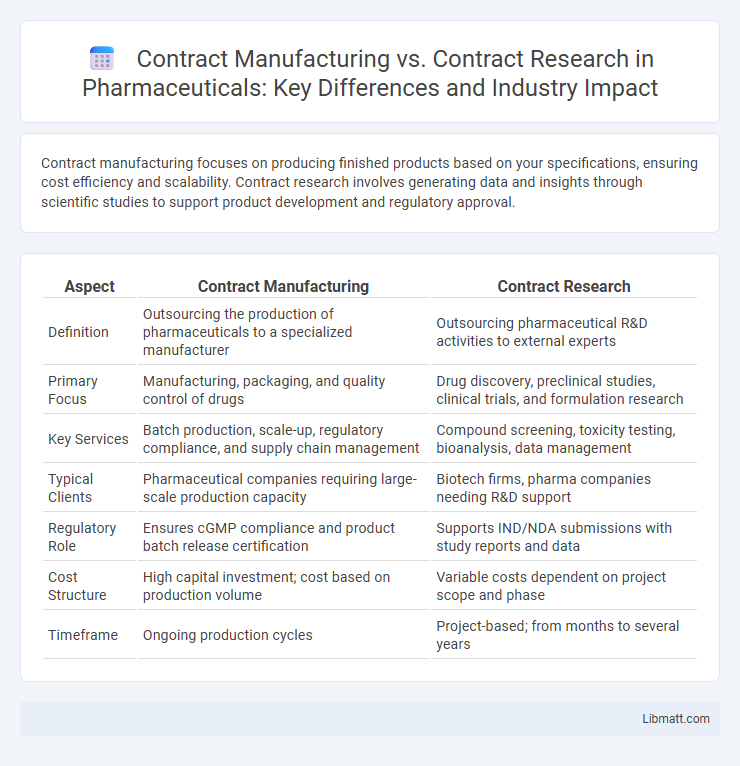

Contract manufacturing focuses on producing finished products based on your specifications, ensuring cost efficiency and scalability. Contract research involves generating data and insights through scientific studies to support product development and regulatory approval.

Table of Comparison

| Aspect | Contract Manufacturing | Contract Research |

|---|---|---|

| Definition | Outsourcing the production of pharmaceuticals to a specialized manufacturer | Outsourcing pharmaceutical R&D activities to external experts |

| Primary Focus | Manufacturing, packaging, and quality control of drugs | Drug discovery, preclinical studies, clinical trials, and formulation research |

| Key Services | Batch production, scale-up, regulatory compliance, and supply chain management | Compound screening, toxicity testing, bioanalysis, data management |

| Typical Clients | Pharmaceutical companies requiring large-scale production capacity | Biotech firms, pharma companies needing R&D support |

| Regulatory Role | Ensures cGMP compliance and product batch release certification | Supports IND/NDA submissions with study reports and data |

| Cost Structure | High capital investment; cost based on production volume | Variable costs dependent on project scope and phase |

| Timeframe | Ongoing production cycles | Project-based; from months to several years |

Introduction to Contract Manufacturing and Contract Research

Contract manufacturing involves outsourcing the production of goods to specialized companies that manage manufacturing processes, quality control, and logistics, enabling businesses to reduce costs and scale production efficiently. Contract research refers to outsourcing specialized research activities, such as drug discovery, clinical trials, or product development, to external organizations with expertise and advanced facilities. Both models enhance operational flexibility and innovation by leveraging external resources in the pharmaceutical, biotechnology, and manufacturing industries.

Defining Contract Manufacturing

Contract manufacturing involves outsourcing the production of goods to a third-party company that specializes in manufacturing processes. This allows your business to leverage specialized facilities and expertise without investing in costly equipment or infrastructure. Contract manufacturing ensures scalable, efficient production tailored to your product specifications.

Defining Contract Research

Contract research involves outsourcing specific scientific or technical investigations to third-party organizations specializing in data generation, experiment design, and analysis. It focuses on discovery, development, and validation phases, providing expertise in areas such as clinical trials, preclinical studies, and laboratory research. Unlike contract manufacturing, which centers on production and scale-up, contract research is primarily dedicated to innovation and knowledge creation within the product development lifecycle.

Key Differences Between Contract Manufacturing and Contract Research

Contract manufacturing involves the production of goods or components by a third party based on a client's specifications, ensuring scalability and cost-efficiency in manufacturing processes. Contract research focuses on conducting scientific studies, experiments, or product development tasks outsourced to specialized research organizations to advance innovation and regulatory compliance. The key differences lie in contract manufacturing emphasizing production and supply chain management, while contract research centers on discovery, analysis, and development activities.

Benefits of Contract Manufacturing

Contract manufacturing offers significant benefits including cost reduction through economies of scale, access to specialized production expertise, and faster time-to-market by leveraging established manufacturing processes. It allows companies to focus on core competencies like research and marketing while outsourcing complex production tasks to experienced partners. Enhanced product quality and compliance with regulatory standards are often achieved due to the contract manufacturer's industry knowledge and technical capabilities.

Advantages of Contract Research

Contract research offers the advantage of accessing specialized scientific expertise and advanced technologies without the need for in-house investment. It accelerates your product development timeline by leveraging the experience and infrastructure of established research organizations. This approach reduces operational risks and ensures compliance with regulatory standards, enhancing the quality and reliability of research outcomes.

Ideal Scenarios for Choosing Contract Manufacturing

Contract manufacturing is ideal for businesses aiming to scale production rapidly without investing in additional facilities or equipment. Companies seeking to maintain focus on core competencies such as product design or market development benefit from outsourcing manufacturing to specialized firms that ensure quality control and regulatory compliance. This approach also suits startups and small to medium-sized enterprises that require cost-effective solutions to meet fluctuating demand while minimizing capital expenditures.

When to Opt for Contract Research Services

Opt for contract research services when specialized expertise and advanced scientific capabilities are needed to conduct complex experiments, product development, or regulatory compliance assessments. Contract research organizations (CROs) provide critical support in preclinical and clinical trials, enabling faster innovation and reducing time-to-market for pharmaceutical, biotech, and medical device companies. Choosing CROs is ideal when companies lack in-house research infrastructure or require scalable resources to meet project-specific demands efficiently.

Cost Considerations: Manufacturing vs Research

Contract manufacturing typically involves higher upfront costs due to expenses related to production facilities, raw materials, and quality control, whereas contract research primarily incurs costs associated with specialized expertise, laboratory equipment, and time-intensive experimentation. Manufacturing costs are largely variable and scale with production volume, while research costs are more fixed and driven by the complexity and duration of scientific investigation. Businesses must weigh these financial differences when choosing between contract manufacturing and contract research services, ensuring alignment with budget constraints and project objectives.

Making the Right Choice for Your Business

Choosing between contract manufacturing and contract research depends on your business goals, timelines, and resource availability. Contract manufacturing focuses on producing finished products efficiently, while contract research emphasizes developing new formulations or technologies. Aligning your priorities with the specific strengths of each service ensures the best investment for your company's growth and innovation.

Contract manufacturing vs contract research Infographic

libmatt.com

libmatt.com