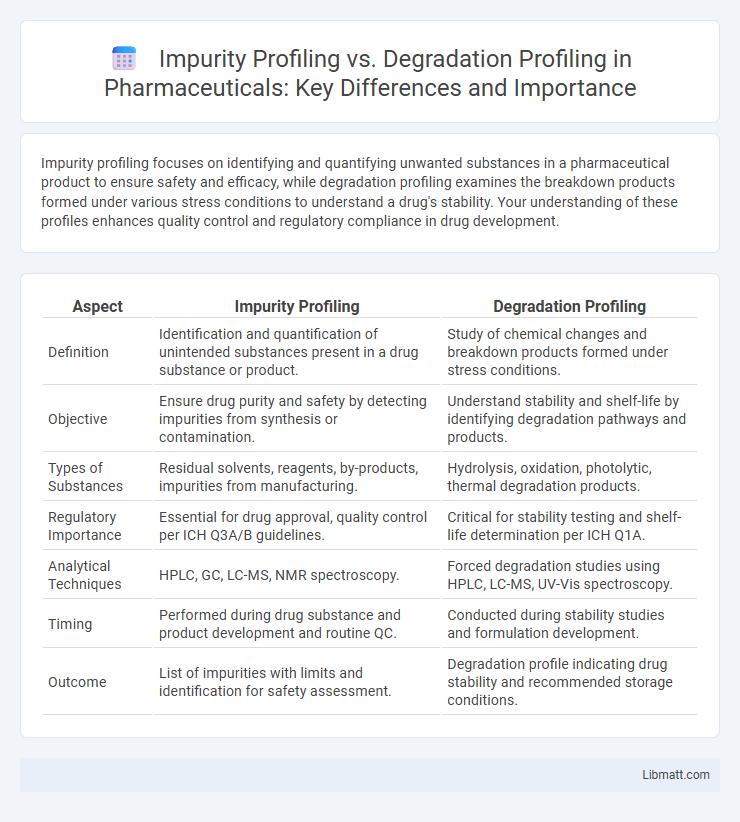

Impurity profiling focuses on identifying and quantifying unwanted substances in a pharmaceutical product to ensure safety and efficacy, while degradation profiling examines the breakdown products formed under various stress conditions to understand a drug's stability. Your understanding of these profiles enhances quality control and regulatory compliance in drug development.

Table of Comparison

| Aspect | Impurity Profiling | Degradation Profiling |

|---|---|---|

| Definition | Identification and quantification of unintended substances present in a drug substance or product. | Study of chemical changes and breakdown products formed under stress conditions. |

| Objective | Ensure drug purity and safety by detecting impurities from synthesis or contamination. | Understand stability and shelf-life by identifying degradation pathways and products. |

| Types of Substances | Residual solvents, reagents, by-products, impurities from manufacturing. | Hydrolysis, oxidation, photolytic, thermal degradation products. |

| Regulatory Importance | Essential for drug approval, quality control per ICH Q3A/B guidelines. | Critical for stability testing and shelf-life determination per ICH Q1A. |

| Analytical Techniques | HPLC, GC, LC-MS, NMR spectroscopy. | Forced degradation studies using HPLC, LC-MS, UV-Vis spectroscopy. |

| Timing | Performed during drug substance and product development and routine QC. | Conducted during stability studies and formulation development. |

| Outcome | List of impurities with limits and identification for safety assessment. | Degradation profile indicating drug stability and recommended storage conditions. |

Introduction to Impurity Profiling and Degradation Profiling

Impurity profiling involves the identification and quantification of unwanted substances present in a pharmaceutical compound, ensuring drug purity and safety throughout production and storage. Degradation profiling focuses specifically on the chemical changes and breakdown products formed under various environmental conditions, revealing drug stability and shelf-life. Both profiling techniques are critical for comprehensive quality control and regulatory compliance in drug development.

Importance of Profiling in Pharmaceutical Analysis

Impurity profiling and degradation profiling are critical components in pharmaceutical analysis, ensuring drug safety and efficacy by identifying and quantifying unwanted substances. These processes help detect contaminants and degradation products that can affect the stability and therapeutic performance of medications. Accurate profiling enables you to maintain regulatory compliance and optimize formulation stability throughout the drug's shelf life.

Defining Impurity Profiling

Impurity profiling involves the systematic identification, quantification, and characterization of undesired chemical substances within pharmaceutical products to ensure drug safety and efficacy. It focuses on detecting process-related impurities, residual solvents, and degradation products formed during manufacturing, storage, or handling. Accurate impurity profiling supports regulatory compliance and quality control by revealing the chemical purity and stability of drug substances and formulations.

Defining Degradation Profiling

Degradation profiling involves the systematic identification and quantification of breakdown products formed from active pharmaceutical ingredients (APIs) under various stress conditions such as heat, light, humidity, and pH. This process helps predict the stability and shelf-life of drug substances by revealing potential degradation pathways and reaction mechanisms. Impurity profiling, in contrast, encompasses the broader analysis of all impurities including those introduced during synthesis, manufacturing, or storage, highlighting the unique focus of degradation profiling on product stability and chemical integrity over time.

Key Differences between Impurity Profiling and Degradation Profiling

Impurity profiling identifies and quantifies all impurities present in a pharmaceutical product, including process-related and unknown contaminants, ensuring overall product purity and safety. Degradation profiling specifically monitors the chemical changes and breakdown products formed under stress conditions like heat, light, or humidity, focusing on the product's stability and shelf-life. While impurity profiling covers both inherent and extrinsic impurities, degradation profiling is centered on degradation pathways and their impact on drug efficacy.

Analytical Techniques for Impurity Profiling

Analytical techniques for impurity profiling include high-performance liquid chromatography (HPLC), gas chromatography (GC), mass spectrometry (MS), and nuclear magnetic resonance (NMR) spectroscopy, which provide detailed identification and quantification of impurities in pharmaceutical substances. Impurity profiling focuses on trace-level contaminants, requiring highly sensitive and specific methods to ensure drug safety and regulatory compliance. Your selection of analytical techniques should align with the chemical nature of impurities and the complexity of the drug matrix for accurate impurity characterization.

Analytical Techniques for Degradation Profiling

Degradation profiling primarily employs high-performance liquid chromatography (HPLC), mass spectrometry (MS), and infrared spectroscopy (IR) to identify and quantify degradation products formed under stress conditions, offering insights into drug stability. These analytical techniques allow for precise monitoring of chemical changes, ensuring your pharmaceutical formulation maintains efficacy and safety throughout its shelf life. Impurity profiling, in contrast, broadly focuses on detecting trace-level impurities but does not specifically target degradation-related compounds formed during product aging.

Regulatory Perspectives on Profiling Methods

Regulatory agencies emphasize stringent impurity profiling to ensure drug safety by identifying and quantifying all potential impurities within pharmaceutical products. Degradation profiling focuses on understanding the chemical stability and identifying degradation products formed under various stress conditions, which is critical for shelf-life determination and product quality. Your compliance strategy should align with guidelines from ICH Q3A, Q3B, and Q1A, which distinctly address impurity limits and forced degradation studies.

Challenges and Limitations in Profiling

Impurity profiling faces challenges such as detecting low-level impurities amid complex matrices and distinguishing structurally similar contaminants, requiring highly sensitive analytical techniques like LC-MS and NMR. Degradation profiling is limited by the variability in degradation pathways under different stress conditions, making it difficult to predict all potential degradation products and their impact on drug stability. Both profiles demand robust method validation and comprehensive understanding of chemical behavior to ensure accurate identification and quantification throughout the drug lifecycle.

Future Trends in Impurity and Degradation Profiling

Future trends in impurity and degradation profiling emphasize the integration of advanced analytical techniques such as high-resolution mass spectrometry and machine learning algorithms for more accurate detection and characterization of trace impurities and degradation products. The adoption of real-time monitoring and continuous manufacturing processes enhances the ability to track impurity formation dynamically, improving drug safety and quality control. Regulatory frameworks are evolving to mandate more comprehensive impurity identification and degradation pathway elucidation, driving innovation in analytical methodologies and predictive modeling.

Impurity profiling vs degradation profiling Infographic

libmatt.com

libmatt.com