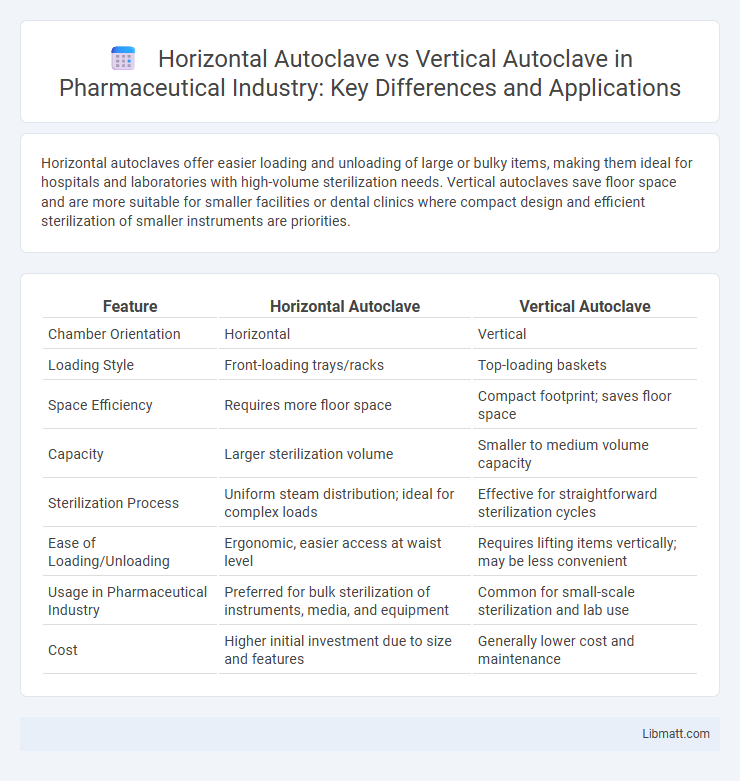

Horizontal autoclaves offer easier loading and unloading of large or bulky items, making them ideal for hospitals and laboratories with high-volume sterilization needs. Vertical autoclaves save floor space and are more suitable for smaller facilities or dental clinics where compact design and efficient sterilization of smaller instruments are priorities.

Table of Comparison

| Feature | Horizontal Autoclave | Vertical Autoclave |

|---|---|---|

| Chamber Orientation | Horizontal | Vertical |

| Loading Style | Front-loading trays/racks | Top-loading baskets |

| Space Efficiency | Requires more floor space | Compact footprint; saves floor space |

| Capacity | Larger sterilization volume | Smaller to medium volume capacity |

| Sterilization Process | Uniform steam distribution; ideal for complex loads | Effective for straightforward sterilization cycles |

| Ease of Loading/Unloading | Ergonomic, easier access at waist level | Requires lifting items vertically; may be less convenient |

| Usage in Pharmaceutical Industry | Preferred for bulk sterilization of instruments, media, and equipment | Common for small-scale sterilization and lab use |

| Cost | Higher initial investment due to size and features | Generally lower cost and maintenance |

Introduction to Autoclaves

Autoclaves are essential sterilization devices utilizing high-pressure saturated steam to eliminate bacteria, viruses, and spores in medical and laboratory settings. Horizontal autoclaves feature a door on the side and a chamber oriented horizontally, facilitating easy loading of large or bulky instruments. Vertical autoclaves have a chamber oriented vertically with a top-opening lid, providing space-efficient design ideal for smaller volumes or limited workspace environments.

What is a Horizontal Autoclave?

A horizontal autoclave is a sterilization device designed with a cylindrical chamber positioned horizontally, allowing instruments and materials to be loaded through a front-facing door. It efficiently uses saturated steam under pressure to eliminate microbial contaminants, making it ideal for sterilizing surgical tools, laboratory equipment, and biohazard waste. This type of autoclave offers uniform steam distribution and easy handling of larger or bulkier items compared to vertical models.

What is a Vertical Autoclave?

A vertical autoclave is a sterilization device designed with a chamber oriented vertically, allowing steam to circulate efficiently around the instruments placed inside. This type of autoclave is typically used in medical, dental, and laboratory settings for sterilizing surgical tools, glassware, and other heat-resistant items. Its design offers space-saving advantages and faster loading compared to horizontal autoclaves, making it ideal for smaller clinics or facilities with limited space.

Key Differences Between Horizontal and Vertical Autoclaves

Horizontal autoclaves feature a side-loading chamber ideal for larger instruments and easy access, while vertical autoclaves have a top-loading design suited for smaller spaces and quicker sterilization cycles. You should consider that horizontal models often provide better visibility and accommodate bulky items, whereas vertical autoclaves typically offer a more compact footprint and faster operation. Differences in steam penetration, loading convenience, and space requirements are crucial factors when selecting the appropriate autoclave for your sterilization needs.

Space Requirements and Installation

Horizontal autoclaves typically demand more floor space due to their longer chambers, making them suitable for facilities with ample room. Vertical autoclaves have a smaller footprint, optimizing installation in labs or clinics with limited space. Installation of horizontal models often requires reinforced flooring to support heavier equipment, while vertical autoclaves are easier to position on standard surfaces due to their compact design.

Sterilization Efficiency and Load Capacity

Horizontal autoclaves generally offer higher sterilization efficiency for large, bulky instruments due to their easier loading and unloading process, allowing steam to circulate uniformly. Vertical autoclaves, while more compact and suitable for smaller spaces, often have limited load capacity and may experience less effective steam penetration in densely packed loads. Choosing the right autoclave depends on your specific sterilization needs and available workspace, balancing efficiency with the volume of instruments processed.

Applications in Various Industries

Horizontal autoclaves excel in sterilizing large medical instruments and laboratory equipment, commonly used in hospitals and pharmaceutical industries due to their easy loading and spacious chambers. Vertical autoclaves are preferred in research labs and small-scale production facilities, offering efficient sterilization for dental tools, microbiological media, and surgical instruments with their compact design. Your choice depends on space availability and specific sterilization needs within healthcare, biotechnology, and food processing industries.

Ease of Operation and Maintenance

Horizontal autoclaves offer easier loading and unloading through side-access doors, enhancing your operational efficiency in sterilizing larger or bulkier items. Vertical autoclaves feature a top-loading design that requires less floor space but can be more challenging to manage due to the lifting and positioning of heavy trays, impacting ergonomics during operation and maintenance. Routine maintenance is generally simpler for horizontal models as their design allows more accessible inspection and cleaning, reducing downtime and ensuring consistent performance.

Cost Comparison: Horizontal vs Vertical Autoclaves

Horizontal autoclaves generally have a higher upfront cost due to their larger chamber size and complex design, making them ideal for bulk sterilization in industrial settings. Vertical autoclaves tend to be more affordable and space-efficient, suitable for smaller laboratories or clinics with limited budgets. Your choice between horizontal and vertical autoclaves should consider both initial investment and long-term operational expenses, including maintenance and energy consumption.

Choosing the Right Autoclave for Your Needs

Selecting the appropriate autoclave depends on sterilization volume, space constraints, and workflow efficiency. Horizontal autoclaves offer larger chamber capacities and easier loading for bulk instruments, making them ideal for high-volume or hospital settings. Vertical autoclaves save floor space with a compact design, suitable for smaller clinics or laboratories requiring quick, frequent sterilization cycles.

Horizontal autoclave vs vertical autoclave Infographic

libmatt.com

libmatt.com