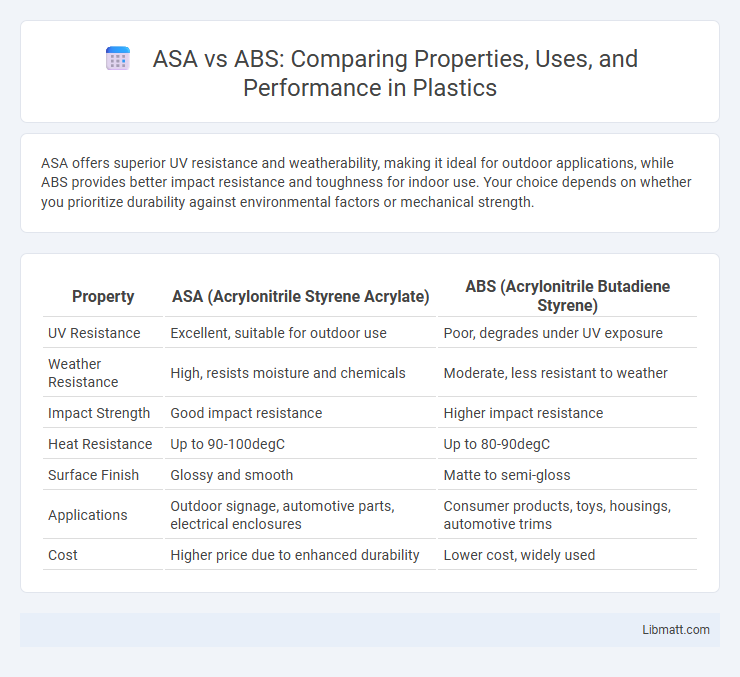

ASA offers superior UV resistance and weatherability, making it ideal for outdoor applications, while ABS provides better impact resistance and toughness for indoor use. Your choice depends on whether you prioritize durability against environmental factors or mechanical strength.

Table of Comparison

| Property | ASA (Acrylonitrile Styrene Acrylate) | ABS (Acrylonitrile Butadiene Styrene) |

|---|---|---|

| UV Resistance | Excellent, suitable for outdoor use | Poor, degrades under UV exposure |

| Weather Resistance | High, resists moisture and chemicals | Moderate, less resistant to weather |

| Impact Strength | Good impact resistance | Higher impact resistance |

| Heat Resistance | Up to 90-100degC | Up to 80-90degC |

| Surface Finish | Glossy and smooth | Matte to semi-gloss |

| Applications | Outdoor signage, automotive parts, electrical enclosures | Consumer products, toys, housings, automotive trims |

| Cost | Higher price due to enhanced durability | Lower cost, widely used |

Overview of ASA and ABS

ASA (Acrylonitrile Styrene Acrylate) and ABS (Acrylonitrile Butadiene Styrene) are thermoplastic polymers widely used in 3D printing and manufacturing due to their durability and impact resistance. ASA offers superior weather resistance and UV stability, making it ideal for outdoor applications, while ABS provides strong mechanical properties and ease of processing for complex designs. Understanding the differences between ASA and ABS helps you select the right material for your project's environmental and performance needs.

Chemical Structure Comparison

ASA (Acrylonitrile Styrene Acrylate) features a terpolymer structure comprising acrylonitrile, styrene, and acrylic ester, providing excellent chemical resistance and UV stability. In contrast, ABS (Acrylonitrile Butadiene Styrene) contains butadiene rubber, which imparts higher impact resistance but lower weatherability compared to ASA. Understanding the chemical structure differences helps you select the right polymer for applications requiring durability and outdoor exposure.

Mechanical Properties: Strength and Durability

ASA exhibits superior UV resistance and weatherability compared to ABS, making it more durable for outdoor applications. Both ASA and ABS offer comparable tensile strength, but ASA's enhanced impact resistance and robustness under prolonged exposure to environmental stress ensure better mechanical performance. ASA maintains its mechanical properties without significant degradation, whereas ABS tends to become brittle and weaken when exposed to sunlight and harsh weather conditions.

Weather and UV Resistance

ASA offers superior weather and UV resistance compared to ABS, making it ideal for outdoor applications exposed to sunlight and harsh environmental conditions. Its polymer structure resists color fading, cracking, and degradation caused by prolonged UV exposure, ensuring durability and aesthetic retention. If your project demands long-lasting performance in outdoor settings, ASA provides a more reliable material choice than ABS.

Printing Ease and Temperature Requirements

ASA offers straightforward printing with moderate temperature requirements, typically extruding between 240degC and 260degC, making it compatible with most standard 3D printers. ABS demands higher extrusion temperatures, often between 230degC and 270degC, and benefits from a heated bed set around 90degC to minimize warping and improve adhesion. Both materials require controlled cooling environments, but ASA's stability under UV exposure makes it easier to print outdoors without significant deformation.

Surface Finish and Post-Processing

ASA offers superior UV resistance and weatherability compared to ABS, resulting in a longer-lasting, vibrant surface finish ideal for outdoor applications. While ABS provides a smoother initial surface with easier sanding and painting due to its finer texture, ASA's inherent resistance reduces the need for extensive post-processing when exposed to harsh environments. Post-processing ASA typically involves minimal polishing and sealing to maintain durability, whereas ABS benefits from more frequent surface treatments to prevent degradation and maintain appearance.

Cost Analysis: ASA vs ABS

ASA (Acrylonitrile Styrene Acrylate) typically commands a higher price than ABS (Acrylonitrile Butadiene Styrene) due to its enhanced UV resistance and weatherability, making it suitable for outdoor applications. ABS remains more cost-effective for indoor uses, offering excellent impact resistance and ease of processing at a lower material and production cost. Manufacturers often select ASA when long-term durability under sunlight exposure justifies the increased investment, whereas ABS is preferred for budget-sensitive projects with minimal environmental stress.

Environmental Impact and Recycling

ASA (Acrylonitrile Styrene Acrylate) and ABS (Acrylonitrile Butadiene Styrene) differ significantly in environmental impact and recycling processes. ASA offers enhanced weather resistance and durability, leading to a longer lifespan and reduced material waste in outdoor applications, while ABS is more susceptible to UV degradation and may require more frequent replacement. Both materials are recyclable, but ASA's chemical structure allows for more efficient recycling with less degradation of polymer properties, promoting sustainability in manufacturing cycles.

Ideal Applications for ASA

ASA (Acrylonitrile Styrene Acrylate) excels in outdoor applications due to its superior UV resistance and weatherability compared to ABS (Acrylonitrile Butadiene Styrene). Ideal uses for ASA include automotive exterior parts, outdoor furniture, and sporting goods where prolonged exposure to sunlight and harsh weather conditions can degrade other materials. Its excellent chemical resistance and color stability ensure long-lasting performance in demanding environments.

Ideal Applications for ABS

ABS (Acrylonitrile Butadiene Styrene) is ideal for automotive parts, consumer electronics housings, and LEGO bricks due to its excellent impact resistance, toughness, and ease of machining. Its high strength-to-weight ratio and thermal stability make it suitable for applications requiring durability and structural integrity. ABS is also favored in prototyping and 3D printing because of its smooth finish and ability to be post-processed easily.

ASA vs ABS Infographic

libmatt.com

libmatt.com