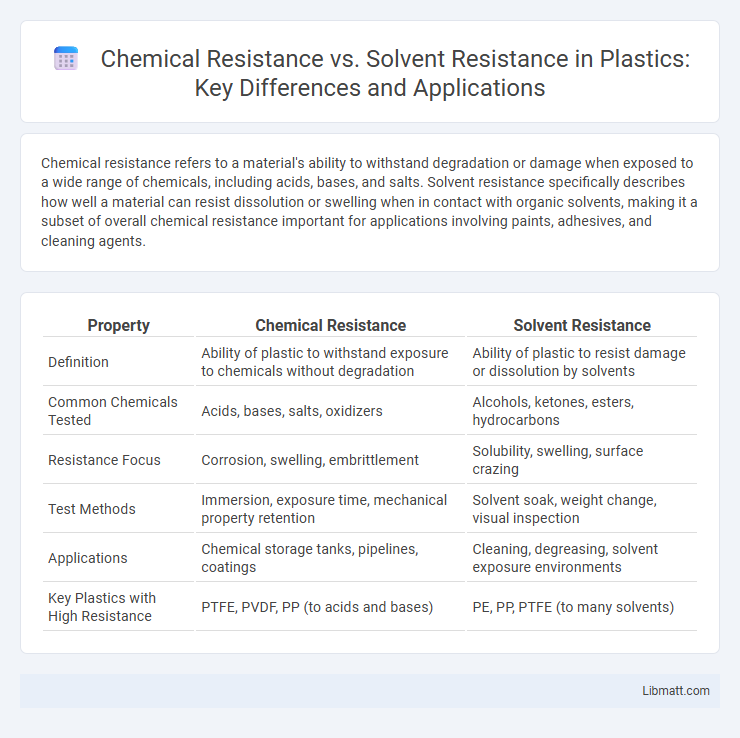

Chemical resistance refers to a material's ability to withstand degradation or damage when exposed to a wide range of chemicals, including acids, bases, and salts. Solvent resistance specifically describes how well a material can resist dissolution or swelling when in contact with organic solvents, making it a subset of overall chemical resistance important for applications involving paints, adhesives, and cleaning agents.

Table of Comparison

| Property | Chemical Resistance | Solvent Resistance |

|---|---|---|

| Definition | Ability of plastic to withstand exposure to chemicals without degradation | Ability of plastic to resist damage or dissolution by solvents |

| Common Chemicals Tested | Acids, bases, salts, oxidizers | Alcohols, ketones, esters, hydrocarbons |

| Resistance Focus | Corrosion, swelling, embrittlement | Solubility, swelling, surface crazing |

| Test Methods | Immersion, exposure time, mechanical property retention | Solvent soak, weight change, visual inspection |

| Applications | Chemical storage tanks, pipelines, coatings | Cleaning, degreasing, solvent exposure environments |

| Key Plastics with High Resistance | PTFE, PVDF, PP (to acids and bases) | PE, PP, PTFE (to many solvents) |

Understanding Chemical Resistance

Chemical resistance refers to a material's ability to withstand damage caused by chemical reactions, such as corrosion or degradation, while solvent resistance specifically describes a material's capacity to resist dissolution or swelling when exposed to solvents. Understanding chemical resistance involves evaluating how different substances interact with materials on a molecular level, helping you select the right product for environments involving exposure to acids, bases, or organic solvents. Proper assessment ensures durability and performance in applications ranging from industrial coatings to laboratory equipment.

Defining Solvent Resistance

Solvent resistance refers to a material's ability to withstand damage or degradation when exposed specifically to chemical solvents, which are substances capable of dissolving other materials. Unlike general chemical resistance, which covers exposure to a wide range of chemicals including acids, bases, and salts, solvent resistance focuses on the interaction with organic solvents such as alcohols, ketones, and hydrocarbons. Understanding solvent resistance is crucial for selecting materials that maintain their integrity and performance in environments where exposure to solvents is frequent or unavoidable.

Key Differences: Chemical vs. Solvent Resistance

Chemical resistance refers to a material's ability to withstand various chemicals such as acids, bases, and salts without degradation, while solvent resistance specifically measures how well a material resists dissolution or damage from organic solvents like alcohols and hydrocarbons. The key differences lie in the types of substances involved--chemical resistance covers a broader spectrum including corrosive agents, whereas solvent resistance targets compounds that can dissolve or swell the material. Understanding these distinctions helps you select materials that maintain integrity in environments exposed to either corrosive chemicals or aggressive solvents.

Factors Affecting Chemical Resistance

Chemical resistance depends on the material's molecular structure, temperature, concentration, and duration of exposure to chemicals, influencing its ability to withstand corrosive substances. Solvent resistance is specifically affected by the polarity and solubility parameters of the solvent relative to the material, causing swelling or degradation when mismatched. Understanding these factors helps you select materials that maintain integrity in harsh chemical environments, ensuring durability and safety.

Influences on Solvent Resistance

Solvent resistance is primarily influenced by the chemical composition and molecular structure of the material, determining its ability to withstand degradation or swelling when exposed to specific solvents. Factors such as temperature, solvent polarity, exposure duration, and concentration significantly affect solvent resistance, while cross-linking density and degree of polymerization also play crucial roles. Understanding these parameters enables you to select materials with optimal solvent resistance for applications requiring robust chemical exposure protection.

Common Materials with High Chemical Resistance

Common materials with high chemical resistance include polytetrafluoroethylene (PTFE), polyethylene (PE), and stainless steel, which effectively withstand corrosive substances and aggressive chemicals. PTFE exhibits exceptional resistance to acids, bases, and organic solvents, making it ideal for chemical processing equipment. Stainless steel offers durability and resistance against oxidizers and solvents, while polyethylene resists alkalis and many solvents, used broadly in storage containers and piping systems.

Solvent Resistance in Industrial Applications

Solvent resistance in industrial applications refers to a material's ability to withstand degradation or dissolution when exposed to various organic solvents such as acetone, alcohols, and hydrocarbons. This property is critical for coatings, adhesives, and sealants used in chemical processing, automotive, and pharmaceutical industries where frequent solvent exposure can compromise performance and durability. Selecting materials with high solvent resistance ensures longevity, maintains structural integrity, and prevents contamination or failure in harsh industrial environments.

Testing Methods for Resistance Performance

Testing methods for chemical resistance and solvent resistance primarily involve standardized procedures such as ASTM D543 and ISO 175, which expose materials to specific chemicals or solvents under controlled conditions to evaluate degradation, swelling, and weight loss. Immersion testing, spot testing, and dynamic exposure simulate real-world scenarios, assessing the durability and compatibility of polymers, coatings, and elastomers with aggressive substances. Quantitative analysis using spectroscopic techniques, mechanical testing, and visual inspections ensures accurate measurement of resistance performance critical for industrial applications.

Importance in Material Selection

Chemical resistance determines how well a material withstands exposure to various chemicals without degrading, while solvent resistance specifically refers to a material's ability to resist organic solvents. Understanding these properties is crucial in material selection to ensure durability and safety in environments involving aggressive substances. Choosing materials with appropriate chemical and solvent resistance protects Your equipment from corrosion and extends its operational lifespan.

Future Trends in Resistance Technology

Future trends in chemical resistance and solvent resistance technology emphasize the development of advanced polymer composites and nanomaterials that enhance durability and performance under extreme conditions. Innovations in smart coatings incorporating self-healing and adaptive properties enable surfaces to withstand a broader spectrum of aggressive chemicals and solvents. Your industrial applications will benefit from these breakthroughs by achieving longer service life, reduced maintenance costs, and improved safety standards.

Chemical resistance vs solvent resistance Infographic

libmatt.com

libmatt.com