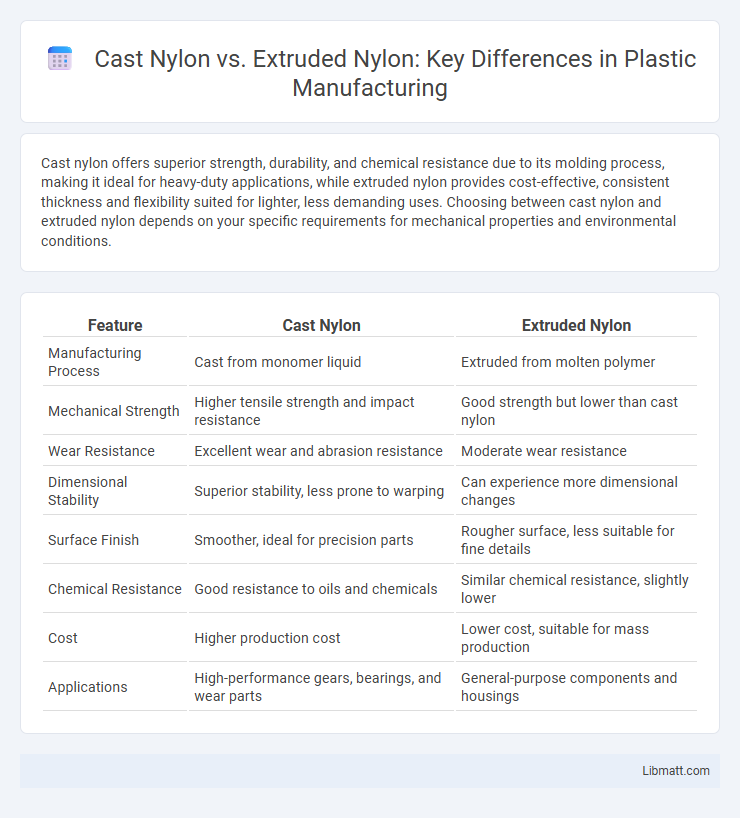

Cast nylon offers superior strength, durability, and chemical resistance due to its molding process, making it ideal for heavy-duty applications, while extruded nylon provides cost-effective, consistent thickness and flexibility suited for lighter, less demanding uses. Choosing between cast nylon and extruded nylon depends on your specific requirements for mechanical properties and environmental conditions.

Table of Comparison

| Feature | Cast Nylon | Extruded Nylon |

|---|---|---|

| Manufacturing Process | Cast from monomer liquid | Extruded from molten polymer |

| Mechanical Strength | Higher tensile strength and impact resistance | Good strength but lower than cast nylon |

| Wear Resistance | Excellent wear and abrasion resistance | Moderate wear resistance |

| Dimensional Stability | Superior stability, less prone to warping | Can experience more dimensional changes |

| Surface Finish | Smoother, ideal for precision parts | Rougher surface, less suitable for fine details |

| Chemical Resistance | Good resistance to oils and chemicals | Similar chemical resistance, slightly lower |

| Cost | Higher production cost | Lower cost, suitable for mass production |

| Applications | High-performance gears, bearings, and wear parts | General-purpose components and housings |

Introduction to Cast Nylon and Extruded Nylon

Cast Nylon is produced by polymerizing caprolactam in a mold, resulting in a dense, strong material with excellent wear resistance and low friction properties. Extruded Nylon is made by melting and forcing nylon pellets through a die to form continuous shapes, providing uniform strength and smooth surfaces ideal for various machining applications. Your choice between cast and extruded nylon depends on the required mechanical properties and manufacturing process suited to your project needs.

Manufacturing Processes Overview

Cast nylon is produced by polymerizing nylon monomers in a mold, resulting in a denser, more uniform material with enhanced mechanical properties and better fatigue resistance. Extruded nylon is made by melting nylon pellets and forcing them through a shaped die, creating consistent shapes with good surface finish but slightly less strength compared to cast nylon. Understanding these manufacturing processes helps you select the right nylon type for applications requiring specific durability and precision.

Material Properties Comparison

Cast nylon exhibits superior mechanical strength, better wear resistance, and higher impact toughness compared to extruded nylon, making it ideal for heavy-duty applications. Extruded nylon offers tighter dimensional tolerances and a smoother surface finish, which suits precision components requiring consistent geometry. Understanding these material properties helps you select the optimal nylon type for your specific engineering requirements.

Strength and Durability Differences

Cast nylon offers superior strength and durability due to its denser molecular structure, resulting in enhanced impact resistance and wear properties compared to extruded nylon. The casting process creates fewer internal stresses, making cast nylon more resistant to fatigue and cracking under heavy loads. Extruded nylon, while still strong, typically exhibits lower mechanical strength and is more prone to moisture absorption, which can reduce its long-term durability.

Thermal and Chemical Resistance

Cast nylon exhibits superior thermal resistance, maintaining stability at higher temperatures up to 260degC, compared to extruded nylon, which typically withstands temperatures around 220degC. Chemically, cast nylon offers enhanced resistance to oils, fuels, and solvents due to its denser molecular structure, while extruded nylon is more susceptible to chemical degradation and moisture absorption. These properties make cast nylon preferable in high-temperature, chemically aggressive environments requiring durability and longevity.

Applications and Industry Uses

Cast Nylon offers superior strength and durability, making it ideal for heavy-duty applications in industries such as automotive, aerospace, and industrial machinery where wear resistance is critical. Extruded Nylon provides better dimensional stability and is commonly used in consumer goods, electrical components, and packaging due to its cost-effectiveness and ease of fabrication. Your choice between Cast Nylon and Extruded Nylon depends on specific application requirements like load-bearing capacity, wear resistance, and manufacturing precision.

Machinability and Fabrication

Cast nylon offers superior machinability due to its uniform molecular structure, allowing for smoother cuts, tighter tolerances, and reduced tool wear compared to extruded nylon. Your fabrication process may benefit from cast nylon's ability to maintain dimensional stability during machining, which minimizes distortion and improves the overall quality of precision components. Extruded nylon, while easier to produce in large volumes, tends to have variable density that can affect machining consistency and surface finish.

Cost Implications

Cast nylon typically incurs higher production costs due to its complex molding process and superior mechanical properties, making it ideal for high-performance applications with demanding strength and wear resistance requirements. Extruded nylon, being produced through a continuous extrusion process, tends to be more cost-effective and suitable for large-scale manufacturing of standard profiles and components with moderate performance needs. Your selection between cast and extruded nylon will largely depend on balancing budget constraints against the required material performance and production volume.

Environmental Impact and Sustainability

Cast nylon manufacturing generates less environmental waste due to its precise molding process, reducing scrap and energy consumption compared to extruded nylon. Extruded nylon production involves melting and reforming polymers, which typically consumes more energy and produces higher carbon emissions. Cast nylon's chemical resistance and durability contribute to longer product lifespans, lowering material replacement frequency and supporting sustainability goals.

Choosing the Right Nylon for Your Needs

Cast nylon offers superior toughness and wear resistance, making it ideal for heavy-duty applications that require high impact strength and chemical stability. Extruded nylon provides greater dimensional accuracy and smoother surface finishes, suitable for components demanding precise tolerances and consistent material properties. Selecting the right nylon depends on factors such as load-bearing requirements, environmental exposure, and mechanical stress tolerance in your specific application.

Cast Nylon vs Extruded Nylon Infographic

libmatt.com

libmatt.com