Polyamide offers excellent mechanical strength, flexibility, and chemical resistance, making it ideal for textile fibers and engineering plastics, while polyimide excels in high-temperature stability, electrical insulation, and chemical durability, often used in aerospace and electronics. Your choice depends on the application's thermal requirements and mechanical demands, with polyimide preferred for extreme heat and polyamide for versatile, durable everyday uses.

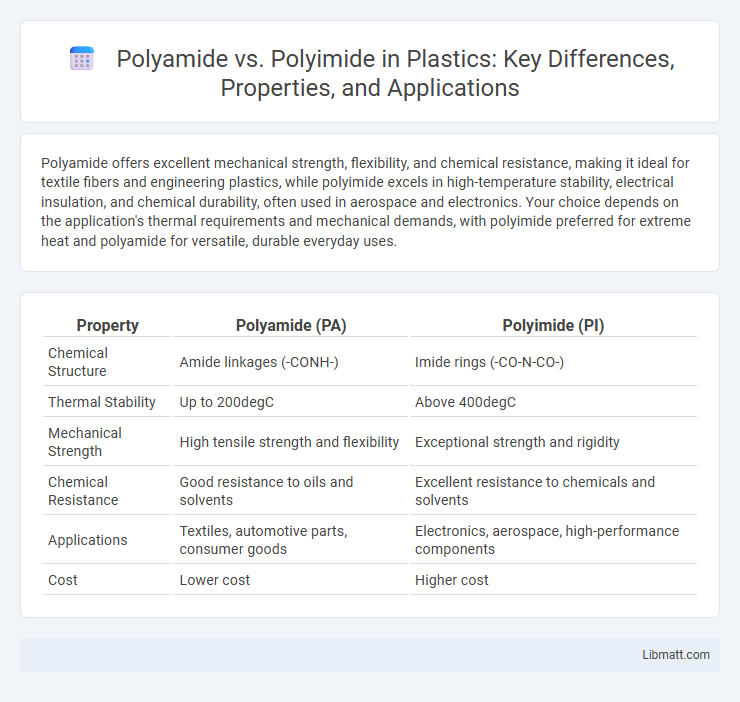

Table of Comparison

| Property | Polyamide (PA) | Polyimide (PI) |

|---|---|---|

| Chemical Structure | Amide linkages (-CONH-) | Imide rings (-CO-N-CO-) |

| Thermal Stability | Up to 200degC | Above 400degC |

| Mechanical Strength | High tensile strength and flexibility | Exceptional strength and rigidity |

| Chemical Resistance | Good resistance to oils and solvents | Excellent resistance to chemicals and solvents |

| Applications | Textiles, automotive parts, consumer goods | Electronics, aerospace, high-performance components |

| Cost | Lower cost | Higher cost |

Introduction to Polyamide and Polyimide

Polyamide and polyimide are high-performance polymers used in various industrial applications due to their exceptional thermal stability and mechanical strength. Polyamide, commonly known as nylon, excels in flexibility and chemical resistance, making it ideal for textiles and engineering plastics. Polyimide offers superior heat resistance and electrical insulating properties, often employed in aerospace, electronics, and advanced composites that demand durability under extreme conditions.

Chemical Structure Differences

Polyamide consists of repeating amide bonds (-CONH-) between carbonyl and amine groups, forming flexible, linear chains ideal for fibers and plastics. Polyimide features imide groups with two carbonyls bonded to a nitrogen atom in a cyclic ring structure, providing exceptional thermal stability and chemical resistance. The difference in ring versus linear structures results in distinct mechanical and thermal properties suitable for different high-performance applications.

Key Physical Properties

Polyamide exhibits excellent tensile strength, flexibility, and chemical resistance, making it suitable for applications requiring durability and impact resistance. Polyimide stands out with exceptional thermal stability, maintaining integrity at temperatures above 400degC, and outstanding electrical insulation properties. Both polymers differ significantly in moisture absorption, with polyamide being more hygroscopic, which can affect dimensional stability in humid environments.

Thermal Stability Comparison

Polyimide exhibits superior thermal stability compared to polyamide, maintaining structural integrity at temperatures above 400degC, while polyamide typically degrades around 200-300degC. The aromatic backbone and imide groups in polyimides contribute to enhanced heat resistance and dimensional stability under extreme conditions. This makes polyimide ideal for high-temperature applications such as aerospace and electronic insulation, whereas polyamide is better suited for moderate temperature environments.

Mechanical Strength and Flexibility

Polyimide exhibits superior mechanical strength compared to polyamide, delivering higher tensile strength and excellent thermal resistance that make it ideal for demanding engineering applications. Polyamide offers greater flexibility and impact resistance, making it suitable for applications requiring more elasticity and toughness in dynamic environments. Both materials have distinct performance profiles, with polyimide favoring rigidity and durability, while polyamide excels in flexibility and resilience.

Electrical Insulation Capabilities

Polyimide offers superior electrical insulation capabilities compared to polyamide due to its high dielectric strength and thermal stability, making it ideal for demanding electronic applications. Polyamide provides good insulation but tends to degrade under high temperatures and prolonged electrical stress. You should consider polyimide for applications requiring reliable performance in extreme electrical and thermal environments.

Common Applications and Industries

Polyamide, known for its strength and flexibility, is widely used in textiles, automotive parts, and consumer goods due to its durability and resistance to abrasion. Polyimide excels in high-temperature environments, making it essential in electronics, aerospace, and industrial insulation applications where thermal stability is critical. Choosing between these polymers depends on your specific industry needs, balancing polyamide's mechanical resilience with polyimide's thermal and chemical resistance.

Processing and Manufacturing Techniques

Polyamide offers versatile processing options including injection molding, extrusion, and blow molding, enabling efficient mass production with relatively low temperatures ranging from 220degC to 320degC. Polyimide requires more specialized manufacturing techniques such as film casting, spin coating, and high-temperature curing processes typically above 350degC, due to its thermosetting nature and superior thermal stability. The distinct processing conditions make polyamide ideal for standard plastic applications, while polyimide suits high-performance industries requiring robust thermal and chemical resistance.

Cost and Availability Factors

Polyamide typically offers lower production costs and greater availability due to its widespread use in textiles and plastics, making it a cost-effective choice for many applications. Polyimide, while more expensive, provides superior thermal stability and chemical resistance, but its specialized manufacturing limits availability and drives higher prices. When evaluating materials for your project, balancing the budget constraints with performance requirements is essential.

Choosing Between Polyamide and Polyimide

Choosing between polyamide and polyimide depends on temperature resistance, mechanical strength, and chemical stability requirements. Polyamide offers excellent toughness and flexibility for applications below 150degC, while polyimide provides superior thermal stability up to 400degC and exceptional dielectric properties. Industries demanding high-performance insulation or extreme environment durability typically prefer polyimide for its unmatched resilience.

Polyamide vs Polyimide Infographic

libmatt.com

libmatt.com