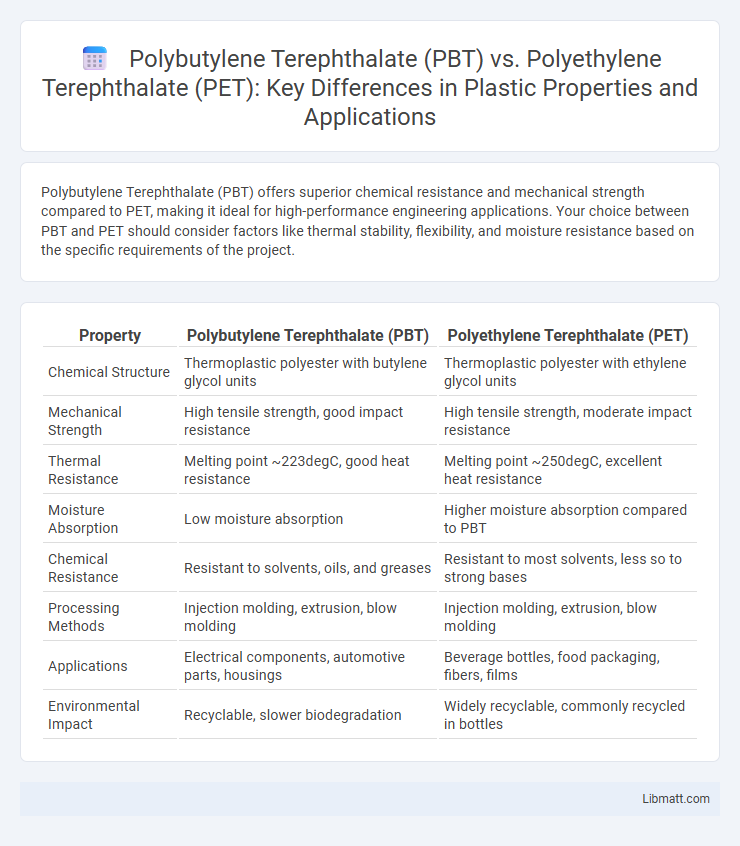

Polybutylene Terephthalate (PBT) offers superior chemical resistance and mechanical strength compared to PET, making it ideal for high-performance engineering applications. Your choice between PBT and PET should consider factors like thermal stability, flexibility, and moisture resistance based on the specific requirements of the project.

Table of Comparison

| Property | Polybutylene Terephthalate (PBT) | Polyethylene Terephthalate (PET) |

|---|---|---|

| Chemical Structure | Thermoplastic polyester with butylene glycol units | Thermoplastic polyester with ethylene glycol units |

| Mechanical Strength | High tensile strength, good impact resistance | High tensile strength, moderate impact resistance |

| Thermal Resistance | Melting point ~223degC, good heat resistance | Melting point ~250degC, excellent heat resistance |

| Moisture Absorption | Low moisture absorption | Higher moisture absorption compared to PBT |

| Chemical Resistance | Resistant to solvents, oils, and greases | Resistant to most solvents, less so to strong bases |

| Processing Methods | Injection molding, extrusion, blow molding | Injection molding, extrusion, blow molding |

| Applications | Electrical components, automotive parts, housings | Beverage bottles, food packaging, fibers, films |

| Environmental Impact | Recyclable, slower biodegradation | Widely recyclable, commonly recycled in bottles |

Introduction to Polybutylene Terephthalate (PBT) and Polyethylene Terephthalate (PET)

Polybutylene Terephthalate (PBT) is a thermoplastic polymer known for its high impact resistance, excellent electrical insulation properties, and chemical stability, making it ideal for automotive components and electrical applications. Polyethylene Terephthalate (PET) is another widely used thermoplastic polymer, valued for its strength, clarity, and moisture resistance, commonly found in packaging materials, beverage bottles, and textile fibers. Understanding the distinct characteristics of PBT and PET helps you choose the right polymer based on mechanical performance, environmental resistance, and end-use requirements.

Chemical Structure and Composition: PBT vs PET

Polybutylene Terephthalate (PBT) and Polyethylene Terephthalate (PET) share a similar aromatic polyester backbone derived from terephthalic acid, but differ in their glycol components--PBT incorporates 1,4-butanediol, while PET contains ethylene glycol. This variation influences their chemical structure, with PBT having a longer alkyl chain leading to increased flexibility and faster crystallization compared to PET. Your choice between PBT and PET will depend on the desired balance of mechanical properties and thermal resistance driven by these compositional differences.

Manufacturing Processes: How PBT and PET Are Made

Polybutylene Terephthalate (PBT) is produced through polycondensation of 1,4-butanediol with terephthalic acid or dimethyl terephthalate, involving melt polymerization under controlled conditions to achieve high molecular weight. Polyethylene Terephthalate (PET) is manufactured via a similar polycondensation reaction between ethylene glycol and terephthalic acid, typically followed by solid-state polymerization to enhance crystallinity and mechanical properties. Understanding these distinct manufacturing processes helps you select the appropriate polymer for applications requiring specific thermal stability and mechanical strength.

Mechanical Properties Comparison

Polybutylene Terephthalate (PBT) exhibits higher impact resistance and superior dimensional stability compared to Polyethylene Terephthalate (PET), making it ideal for applications requiring toughness and heat resistance. PBT's tensile strength ranges between 50-70 MPa, slightly lower than PET's 55-80 MPa, but PBT offers better fatigue resistance and flexibility under stress. PET generally provides higher stiffness and better chemical resistance, often preferred for rigid components and packaging, while PBT's balanced mechanical properties suit electrical housings and automotive parts.

Thermal Stability and Heat Resistance

Polybutylene Terephthalate (PBT) offers superior thermal stability and heat resistance compared to Polyethylene Terephthalate (PET), with a higher melting point around 223degC versus PET's 260degC, making PBT ideal for applications involving prolonged exposure to elevated temperatures. PBT's enhanced crystallinity provides better dimensional stability and reduced warpage under thermal stress, while PET tends to soften and deform more quickly under similar conditions. When selecting materials for heat-sensitive applications, consider how your choice impacts product durability and performance under thermal cycles.

Applications and Uses in Industry

Polybutylene Terephthalate (PBT) is widely used in electrical and automotive industries due to its excellent dimensional stability and resistance to heat and chemicals, making it ideal for connectors, housings, and under-the-hood components. Polyethylene Terephthalate (PET) is predominantly utilized in packaging, particularly for beverage bottles and food containers, due to its clarity, strength, and barrier properties. Your choice between PBT and PET will depend on whether you need high mechanical and thermal performance for industrial parts or superior transparency and recyclability for consumer packaging.

Environmental Impact and Recyclability

Polybutylene Terephthalate (PBT) exhibits a lower carbon footprint compared to Polyethylene Terephthalate (PET) due to its higher durability and resistance to degradation, which extends product life cycles. Both PBT and PET are recyclable, but PET's established global recycling infrastructure leads to higher collection and reprocessing rates, contributing more effectively to reducing plastic waste. Your choice between PBT and PET should consider the availability of local recycling programs to maximize environmental benefits.

Cost and Availability Analysis

Polybutylene Terephthalate (PBT) typically incurs higher production costs compared to Polyethylene Terephthalate (PET) due to its more complex synthesis process and specialized applications. PET benefits from widespread industrial use, resulting in greater availability and lower material costs driven by large-scale manufacturing and recycling infrastructure. Cost-efficiency and accessibility of PET often make it the preferred choice for mass-market applications, while PBT, despite higher costs, is favored for niche uses requiring superior mechanical and thermal properties.

Advantages and Disadvantages of PBT and PET

Polybutylene Terephthalate (PBT) offers superior impact resistance, chemical stability, and fast crystallization compared to Polyethylene Terephthalate (PET), making it ideal for electrical components and automotive parts. PET excels in transparency, moisture barrier properties, and environmental recyclability, widely used in packaging and textile fibers. However, PBT's higher cost and lower UV resistance limit outdoor applications, while PET's lower thermal stability and impact strength restrict use in high-performance engineering parts.

Choosing Between PBT and PET: Key Considerations

When choosing between Polybutylene Terephthalate (PBT) and Polyethylene Terephthalate (PET), key considerations include thermal resistance, mechanical strength, and chemical stability. PBT offers superior electrical insulation and better dimensional stability at elevated temperatures, making it ideal for automotive and electrical applications, while PET provides higher tensile strength and is widely used in packaging and fibers. Your decision should factor in the specific performance requirements, processing conditions, and environmental exposure of your application.

Polybutylene Terephthalate (PBT) vs PET Infographic

libmatt.com

libmatt.com