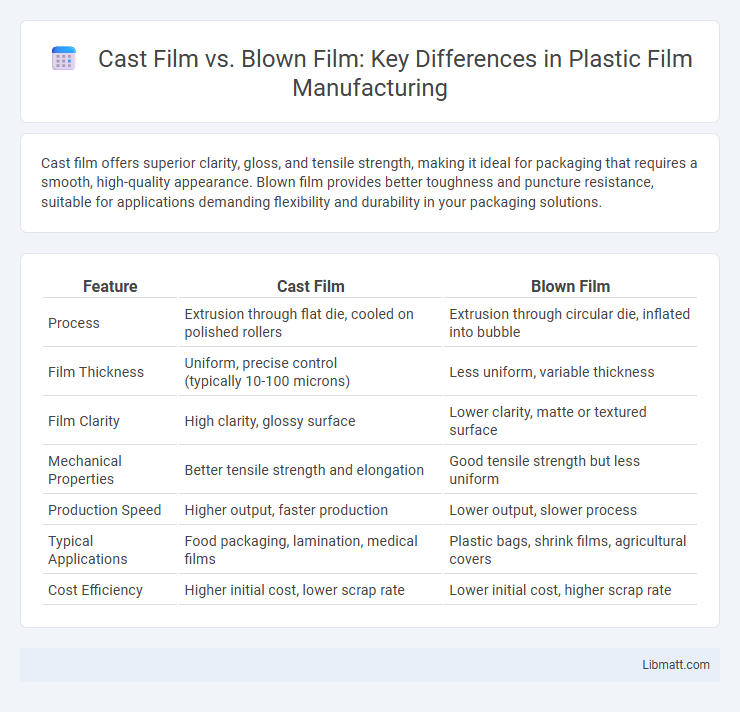

Cast film offers superior clarity, gloss, and tensile strength, making it ideal for packaging that requires a smooth, high-quality appearance. Blown film provides better toughness and puncture resistance, suitable for applications demanding flexibility and durability in your packaging solutions.

Table of Comparison

| Feature | Cast Film | Blown Film |

|---|---|---|

| Process | Extrusion through flat die, cooled on polished rollers | Extrusion through circular die, inflated into bubble |

| Film Thickness | Uniform, precise control (typically 10-100 microns) |

Less uniform, variable thickness |

| Film Clarity | High clarity, glossy surface | Lower clarity, matte or textured surface |

| Mechanical Properties | Better tensile strength and elongation | Good tensile strength but less uniform |

| Production Speed | Higher output, faster production | Lower output, slower process |

| Typical Applications | Food packaging, lamination, medical films | Plastic bags, shrink films, agricultural covers |

| Cost Efficiency | Higher initial cost, lower scrap rate | Lower initial cost, higher scrap rate |

Introduction to Cast Film and Blown Film

Cast film involves extruding molten polymer through a flat die onto a chilled roller, producing thin, uniform films with excellent clarity and surface finish ideal for packaging applications. Blown film is created by extruding polymer through a circular die, inflating it into a bubble, which cools to form a tube-shaped film known for superior strength and versatility in bags and stretch wrap. Understanding the differences between cast film and blown film helps you select the right film type based on desired mechanical properties and end-use requirements.

Overview of Film Extrusion Processes

Cast film extrusion involves melting polymer resin and extruding it through a flat die, forming a thin, uniform sheet rapidly cooled on chilled rollers, producing films with excellent clarity and smooth surfaces. Blown film extrusion melts resin and extrudes it through a circular die, inflating the molten tube with air to create bubbles that expand and cool, resulting in films with superior tensile strength and uniform thickness. Both processes are essential in packaging and plastic manufacturing, with cast film favored for high clarity and blown film preferred for strength and flexibility.

Material Compatibility and Selection

Cast film production offers superior compatibility with a wide variety of materials including polyethylene, polypropylene, and specialty resins, allowing precise control over film properties such as clarity and thickness. Blown film excels in flexibility and impact resistance, making it an ideal choice for applications needing stretchability and toughness, especially with materials like LDPE and LLDPE. Understanding your product requirements will guide the selection between cast and blown film processes to optimize material performance and cost-efficiency.

Production Speed and Efficiency Comparison

Cast film production offers higher efficiency with faster line speeds, typically reaching up to 500 meters per minute, ideal for continuous, uniform sheets. Blown film lines operate at slower speeds, generally between 150 to 300 meters per minute, due to the complex cooling and blowing process required. Your choice impacts overall production speed, with cast film favored for rapid output and blown film preferred when enhanced mechanical properties are essential.

Film Thickness and Uniformity

Cast film offers superior thickness control and uniformity due to the precise cooling process immediately after extrusion, resulting in films with consistent gauge and smooth surface. Blown film tends to have more variability in thickness because of the inflation bubble dynamics, causing fluctuations in gauge across the film width. Choosing cast film ensures your packaging applications benefit from enhanced film clarity and reliable thickness uniformity essential for performance-sensitive products.

Optical Properties: Clarity and Haze

Cast film demonstrates superior optical properties with higher clarity and lower haze, making it ideal for applications requiring transparent packaging. Blown film typically exhibits increased haze due to its cooling process, resulting in less transparency and a slightly frosted appearance. Choosing cast film enhances your product's visual appeal with crisp, clear presentation and reduced distortion.

Mechanical Strength and Durability

Cast film offers superior mechanical strength and durability due to its uniform thickness and smooth molecular alignment, making it ideal for applications requiring high tensile strength and puncture resistance. Blown film, while more flexible and cost-effective, typically exhibits lower mechanical strength and durability because of its variable thickness and uneven molecular orientation. Your choice between the two should consider the balance between strength requirements and production efficiency for optimal performance.

Cost Implications and Scalability

Cast film production generally incurs higher initial equipment costs but offers faster production speeds, leading to lower per-unit costs at scale compared to blown film. Blown film processes require less expensive machinery and offer greater flexibility for small batch sizes, making it more cost-effective for lower volume production. Scalability for cast film is typically superior due to higher throughput and better film homogeneity, while blown film scales more incrementally with added extruder capacity.

Typical Applications and End-Use Markets

Cast film is typically used in applications requiring high clarity and gloss, such as food packaging, labels, and lamination films, favored in markets like retail packaging and medical industries. Blown film excels in durability and elasticity, making it ideal for heavy-duty sacks, agricultural films, and stretch wrap found in construction, agriculture, and industrial sectors. Your choice between cast and blown film depends on the specific end-use market demands for optical properties versus mechanical strength.

Choosing the Right Film Process for Your Needs

Cast film offers superior clarity, uniform thickness, and better tensile strength, making it ideal for applications requiring precision and high-quality printability, such as food packaging and technical laminations. Blown film provides excellent impact resistance, stretchability, and cost efficiency, suitable for products like agricultural films, shopping bags, and heavy-duty packaging. Selecting the right film process depends on factors like desired film properties, production speed, budget constraints, and end-use application requirements.

Cast Film vs Blown Film Infographic

libmatt.com

libmatt.com