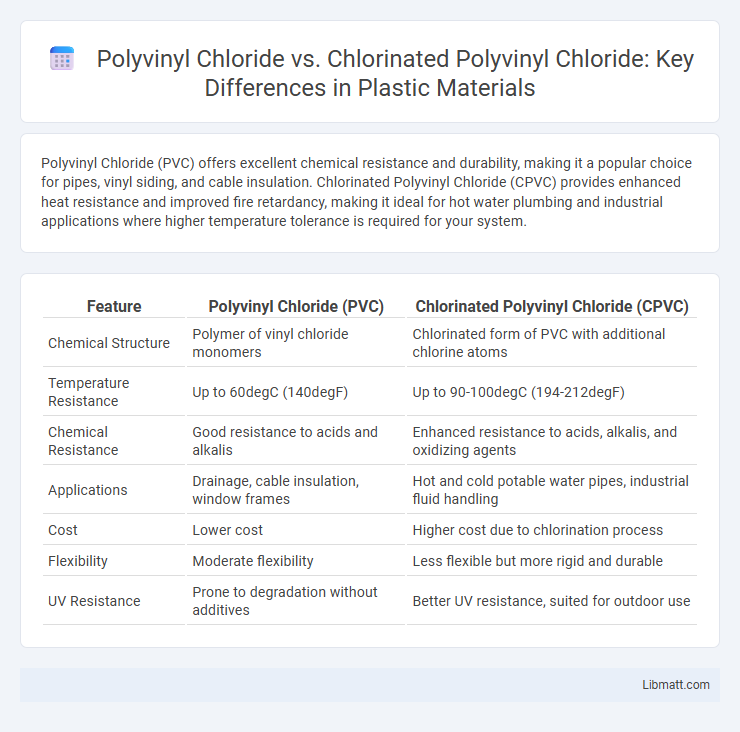

Polyvinyl Chloride (PVC) offers excellent chemical resistance and durability, making it a popular choice for pipes, vinyl siding, and cable insulation. Chlorinated Polyvinyl Chloride (CPVC) provides enhanced heat resistance and improved fire retardancy, making it ideal for hot water plumbing and industrial applications where higher temperature tolerance is required for your system.

Table of Comparison

| Feature | Polyvinyl Chloride (PVC) | Chlorinated Polyvinyl Chloride (CPVC) |

|---|---|---|

| Chemical Structure | Polymer of vinyl chloride monomers | Chlorinated form of PVC with additional chlorine atoms |

| Temperature Resistance | Up to 60degC (140degF) | Up to 90-100degC (194-212degF) |

| Chemical Resistance | Good resistance to acids and alkalis | Enhanced resistance to acids, alkalis, and oxidizing agents |

| Applications | Drainage, cable insulation, window frames | Hot and cold potable water pipes, industrial fluid handling |

| Cost | Lower cost | Higher cost due to chlorination process |

| Flexibility | Moderate flexibility | Less flexible but more rigid and durable |

| UV Resistance | Prone to degradation without additives | Better UV resistance, suited for outdoor use |

Introduction to PVC and CPVC

Polyvinyl Chloride (PVC) is a versatile thermoplastic widely used in plumbing, construction, and electrical insulation due to its durability and cost-effectiveness. Chlorinated Polyvinyl Chloride (CPVC) is a chemically modified version of PVC with added chlorine, enhancing its heat resistance and making it suitable for hot water applications. Understanding the differences between PVC and CPVC can help you choose the right material for your specific needs, especially in temperature-sensitive environments.

Chemical Composition and Structure

Polyvinyl Chloride (PVC) consists of repeating vinyl chloride monomers, characterized by a carbon backbone with chlorine atoms attached, providing rigidity and chemical resistance. Chlorinated Polyvinyl Chloride (CPVC) is produced by chlorinating PVC, increasing its chlorine content and enhancing thermal stability and corrosion resistance. Your choice between PVC and CPVC depends on the required chemical composition and structural attributes for applications like piping or industrial uses.

Manufacturing Processes

Polyvinyl Chloride (PVC) is produced through the polymerization of vinyl chloride monomers using suspension, emulsion, or bulk polymerization methods, resulting in a versatile plastic used in construction and piping. Chlorinated Polyvinyl Chloride (CPVC) is manufactured by chlorinating PVC resin in a post-polymerization process, enhancing its thermal and chemical resistance for applications in hot water systems. Your choice between PVC and CPVC depends on the specific manufacturing differences that impact material properties and performance requirements.

Physical and Mechanical Properties

Polyvinyl Chloride (PVC) exhibits high tensile strength, rigidity, and resistance to abrasion, making it suitable for construction and piping applications. Chlorinated Polyvinyl Chloride (CPVC) offers enhanced thermal stability and chemical resistance compared to PVC, allowing for use in higher temperature environments and aggressive chemical handling. CPVC's improved mechanical properties include better impact resistance and flexibility, which extend its application range beyond that of standard PVC in industrial settings.

Thermal Resistance and Performance

Polyvinyl Chloride (PVC) offers moderate thermal resistance with a maximum operating temperature around 60degC, making it suitable for general applications but limiting performance under high heat. Chlorinated Polyvinyl Chloride (CPVC) enhances thermal resistance significantly, tolerating temperatures up to 90degC or higher, which improves durability and performance in hot water and industrial environments. Your choice between PVC and CPVC should consider temperature demands to ensure optimal long-term performance and reliability.

Corrosion and Chemical Resistance

Polyvinyl chloride (PVC) offers good corrosion resistance against a wide range of acids, alkalis, and salts, making it suitable for general chemical applications. Chlorinated polyvinyl chloride (CPVC) provides enhanced chemical resistance and superior performance in higher temperature environments, particularly against stronger acids, bases, and oxidizing agents. Your choice between PVC and CPVC should consider the specific corrosive chemicals and operating temperatures encountered in your application to ensure optimal durability and safety.

Applications and Industry Usage

Polyvinyl Chloride (PVC) is widely used in construction for pipes, window frames, and electrical cable insulation due to its durability and cost-effectiveness. Chlorinated Polyvinyl Chloride (CPVC) offers enhanced heat resistance, making it ideal for hot water plumbing, industrial fluid handling, and fire sprinkler systems. Your choice between PVC and CPVC depends on application temperature requirements and chemical exposure in industries like residential, commercial, and chemical processing.

Cost Comparison and Economic Considerations

Polyvinyl Chloride (PVC) is generally less expensive than Chlorinated Polyvinyl Chloride (CPVC) due to simpler manufacturing processes and lower raw material costs. CPVC commands a higher price because of additional chlorination steps that enhance its heat resistance and chemical durability, making it suitable for specialized applications such as hot water piping. Economic considerations favor PVC for budget-sensitive projects, while CPVC justifies its premium cost through extended lifespan and performance in high-temperature environments.

Installation, Maintenance, and Lifespan

Polyvinyl Chloride (PVC) offers easy installation due to its lightweight and flexible nature, while Chlorinated Polyvinyl Chloride (CPVC) requires more precise handling because of its increased rigidity and thermal resistance. Maintenance of CPVC is generally lower as it resists corrosion and chemical degradation better than PVC, which may require more frequent inspections for wear and tear in harsh environments. Lifespan of CPVC typically exceeds that of PVC, often lasting 50 years or more in plumbing applications due to its enhanced durability and heat tolerance.

Environmental Impact and Sustainability

Polyvinyl Chloride (PVC) production and disposal generate toxic chemicals, including dioxins and phthalates, raising significant environmental and health concerns, whereas Chlorinated Polyvinyl Chloride (CPVC) offers improved chemical resistance but involves higher chlorine content, increasing potential environmental hazards during incineration. PVC recycling is limited due to additives and contamination, while CPVC recycling is even less established, intensifying sustainability challenges for both materials. Green alternatives and enhanced waste management practices are critical to reducing the carbon footprint and ecological risks associated with PVC and CPVC products.

Polyvinyl Chloride vs Chlorinated Polyvinyl Chloride Infographic

libmatt.com

libmatt.com