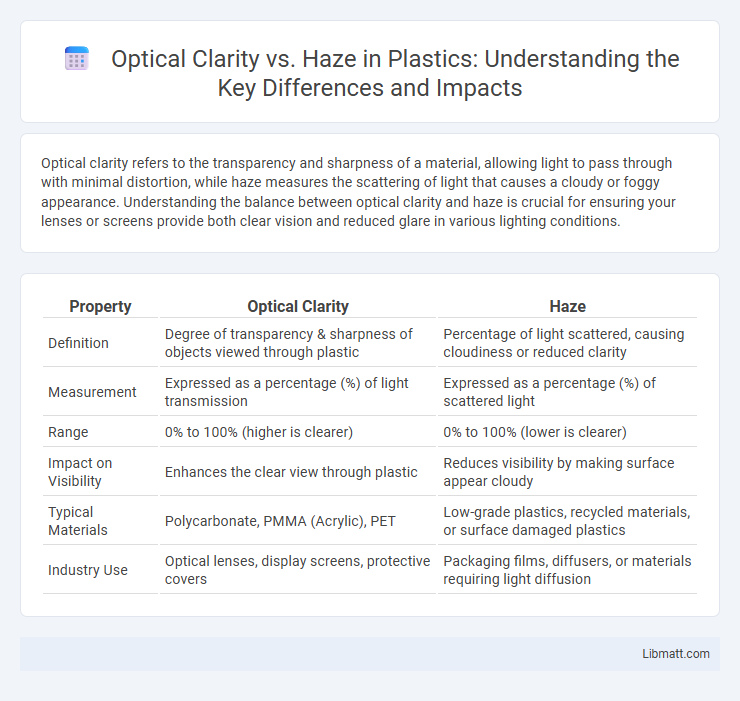

Optical clarity refers to the transparency and sharpness of a material, allowing light to pass through with minimal distortion, while haze measures the scattering of light that causes a cloudy or foggy appearance. Understanding the balance between optical clarity and haze is crucial for ensuring your lenses or screens provide both clear vision and reduced glare in various lighting conditions.

Table of Comparison

| Property | Optical Clarity | Haze |

|---|---|---|

| Definition | Degree of transparency & sharpness of objects viewed through plastic | Percentage of light scattered, causing cloudiness or reduced clarity |

| Measurement | Expressed as a percentage (%) of light transmission | Expressed as a percentage (%) of scattered light |

| Range | 0% to 100% (higher is clearer) | 0% to 100% (lower is clearer) |

| Impact on Visibility | Enhances the clear view through plastic | Reduces visibility by making surface appear cloudy |

| Typical Materials | Polycarbonate, PMMA (Acrylic), PET | Low-grade plastics, recycled materials, or surface damaged plastics |

| Industry Use | Optical lenses, display screens, protective covers | Packaging films, diffusers, or materials requiring light diffusion |

Understanding Optical Clarity

Optical clarity refers to the measure of transparency in a material, indicating how clearly objects can be seen through it without distortion. It is quantitatively assessed by evaluating light transmission and scatter, with higher optical clarity indicating minimal light diffusion. Understanding optical clarity is crucial in industries like eyewear, automotive glass, and display technologies, where visual precision and material quality directly impact user experience.

Defining Haze in Materials

Haze in materials refers to the optical phenomenon where light scattering within the material causes a cloudy or milky appearance, reducing transparency and sharpness. It is quantified by measuring the percentage of light diffused as it passes through a sample, impacting the visual quality of optical components and packaging films. Unlike optical clarity, which denotes the material's ability to transmit light with minimal distortion, haze specifically indicates light scattering that diminishes image crispness and detail visibility.

The Science Behind Light Transmission

Optical clarity refers to the measure of how clearly a material transmits light without distortion, crucial for applications requiring high visibility and precision. Haze quantifies the scattering of light as it passes through a material, causing a milky or foggy appearance that reduces visual sharpness. The science behind light transmission involves understanding how light interacts with a material's surface and internal structure, where minimal scattering and absorption yield high optical clarity, while increased scattering results in greater haze.

Optical Clarity vs Haze: Key Differences

Optical clarity refers to the transparency and clearness of a material, indicating how well it transmits light without distortion, while haze describes the scattering of light that causes a milky or foggy appearance, reducing visibility. High optical clarity materials are essential in applications requiring precise visual performance, such as lenses and display screens. Conversely, high haze values are often controlled to prevent diminished image quality and ensure accurate color representation.

Measuring Optical Clarity and Haze

Optical clarity is measured by the amount of light transmitted through a material without distortion, quantified using a haze meter that evaluates light diffusion. Haze is determined by the percentage of scattered light deviating from the transmitted beam, indicating the cloudiness or fogginess in a material. Accurate measurement of both optical clarity and haze is essential for quality control in industries such as packaging, automotive, and display manufacturing.

Factors Affecting Clarity and Haze

Optical clarity and haze are influenced by surface texture, material composition, and thickness variations that scatter light, reducing transparency. Impurities, microscopic defects, and processing conditions such as temperature and cooling rate also impact haze levels, directly affecting the visual quality of materials like plastics and glass. Your choice of manufacturing techniques and material quality plays a crucial role in achieving optimal clarity with minimal haze for a crisp, clear appearance.

Industrial Applications: Where Clarity or Haze Matters

In industrial applications, optical clarity ensures precision in tasks such as quality control and inspection, where clear visibility is critical for detecting defects and ensuring product integrity. Haze, often preferred in diffusers or safety glass, helps scatter light to reduce glare and improve diffuse illumination in environments like automotive lighting and architectural glazing. You should choose materials with optimal clarity or haze depending on whether transparency or light diffusion better serves your specific manufacturing needs.

Material Choices for Enhanced Optical Performance

Material choices significantly influence optical clarity and haze levels in products such as lenses, displays, and protective screens. High-quality polycarbonate and acrylic materials offer excellent optical clarity with minimal haze, ensuring sharp and clear vision or display performance. Advanced polymer coatings and additives can further reduce haze by optimizing light transmission and scattering properties, resulting in enhanced optical performance.

Testing Standards for Clarity and Haze

Testing standards for optical clarity and haze primarily follow ASTM D1003, which measures total transmittance, haze, and clarity of transparent plastics. Clarity testing quantifies the sharpness of objects viewed through a material, while haze testing assesses the light scattering that causes a milky or foggy appearance. Industry-specific standards may also apply, but ASTM D1003 remains the most widely adopted method for consistent and reliable measurements.

Optimizing Products for Desired Visual Effects

Optimizing products for desired visual effects requires balancing optical clarity and haze to achieve specific visual outcomes. Optical clarity measures the transparency and sharpness of an object, while haze refers to the light scattering that causes a milky or foggy appearance. Precise control of these factors is essential in industries like automotive glazing, display screens, and packaging, where clear visibility or diffused light effects influence user experience and product performance.

Optical Clarity vs Haze Infographic

libmatt.com

libmatt.com