Tackifiers increase the stickiness and adhesion of adhesives, improving their ability to bond surfaces without altering their flexibility. Plasticizers, on the other hand, make materials more flexible and softer by reducing brittleness, enhancing your product's durability and workability.

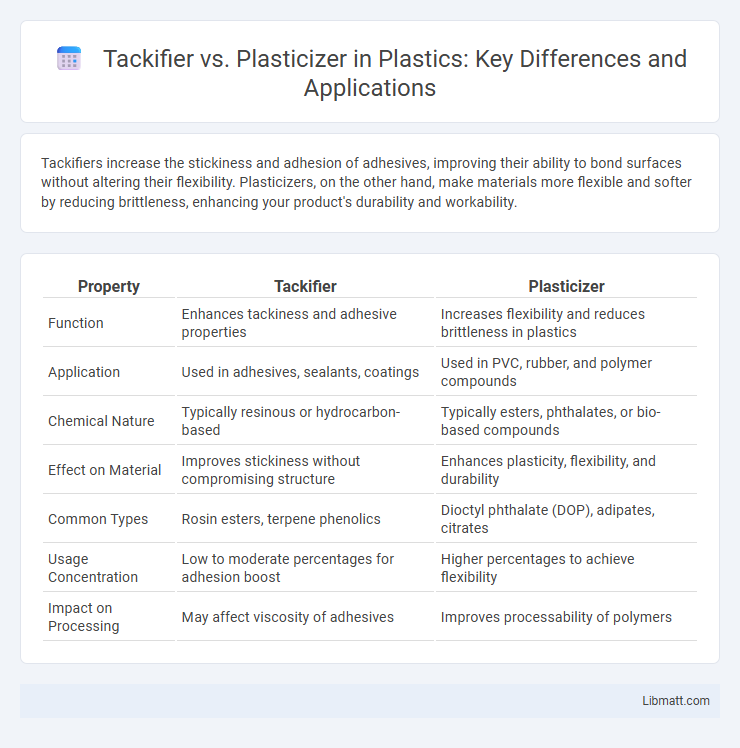

Table of Comparison

| Property | Tackifier | Plasticizer |

|---|---|---|

| Function | Enhances tackiness and adhesive properties | Increases flexibility and reduces brittleness in plastics |

| Application | Used in adhesives, sealants, coatings | Used in PVC, rubber, and polymer compounds |

| Chemical Nature | Typically resinous or hydrocarbon-based | Typically esters, phthalates, or bio-based compounds |

| Effect on Material | Improves stickiness without compromising structure | Enhances plasticity, flexibility, and durability |

| Common Types | Rosin esters, terpene phenolics | Dioctyl phthalate (DOP), adipates, citrates |

| Usage Concentration | Low to moderate percentages for adhesion boost | Higher percentages to achieve flexibility |

| Impact on Processing | May affect viscosity of adhesives | Improves processability of polymers |

Introduction to Tackifiers and Plasticizers

Tackifiers are specialized additives that increase adhesion in products like adhesives, enhancing tackiness without affecting flexibility. Plasticizers improve the flexibility and durability of polymers by reducing brittleness, making materials softer and easier to process. Understanding the distinct roles of tackifiers and plasticizers helps you optimize performance in formulations requiring specific adhesive or flexible properties.

Defining Tackifiers: Role and Applications

Tackifiers are specialized adhesives additives that enhance the stickiness and bond strength of pressure-sensitive adhesives (PSAs) by increasing their tack or initial adhesion. These resins, typically derived from rosin, hydrocarbon, or terpene sources, are crucial in applications such as labels, tapes, and coatings where immediate adhesion is required. Unlike plasticizers, which primarily improve flexibility and durability, tackifiers specifically target surface tack and adhesive performance in products like medical dressings and packaging materials.

Understanding Plasticizers: Functions and Uses

Plasticizers enhance the flexibility and workability of polymers by reducing intermolecular forces, which improves material softness and durability. They are commonly used in PVC formulations to produce flexible products like cables, flooring, and medical devices. Unlike tackifiers that increase stickiness, plasticizers primarily act to improve polymer elasticity and processability.

Key Chemical Differences

Tackifiers are high molecular weight resins used primarily to enhance adhesion by increasing the stickiness of adhesives, whereas plasticizers are low molecular weight compounds designed to improve flexibility and reduce brittleness in polymers. Chemically, tackifiers typically consist of hydrocarbon resins or rosin derivatives with polar functional groups that promote intermolecular bonding, while plasticizers are often phthalates, citrates, or adipates that insert between polymer chains to increase free volume and mobility. The distinct molecular weight and polarity differences directly influence their roles in modifying material properties such as tackiness versus elasticity.

Impact on Material Properties

Tackifiers enhance adhesive strength and improve the stickiness of materials without significantly increasing flexibility, making them ideal for pressure-sensitive adhesives. Plasticizers, in contrast, increase the flexibility and elongation of polymers by reducing intermolecular forces, which can decrease hardness and tensile strength. Your choice between tackifiers and plasticizers fundamentally impacts the balance between adhesion and flexibility in the final product.

Selection Criteria for Formulations

Tackifier and plasticizer selection criteria for formulations depend on the desired adhesive properties and flexibility requirements. Tackifiers enhance stickiness and improve adhesion strength, while plasticizers increase flexibility and reduce brittleness in polymer matrices. Your formulation should balance tackifier concentration to achieve optimal tack without compromising flexibility, and incorporate plasticizers to maintain softness and elongation.

Common Industries Utilizing Tackifiers and Plasticizers

Tackifiers are extensively used in the adhesives industry to enhance tack and stickiness in products like pressure-sensitive tapes and labels. Plasticizers find broad application in the plastics and rubber industries, improving flexibility and durability in items such as PVC flooring, automotive parts, and wire coatings. Both additives are critical in packaging, construction, and automotive sectors for optimizing material performance.

Compatibility with Polymers and Resins

Tackifiers exhibit high compatibility with natural and synthetic polymers such as ethylene-vinyl acetate (EVA) and styrene-butadiene rubber (SBR), enhancing adhesive properties by improving tack and cohesion. Plasticizers are compatible with flexible polymers like polyvinyl chloride (PVC) and polyurethane, optimizing flexibility and processability without significantly altering adhesive strength. The choice between tackifier and plasticizer depends on the target polymer system and desired balance of adhesion versus flexibility.

Environmental and Safety Considerations

Tackifiers generally have lower volatility and reduced emission of harmful fumes compared to plasticizers, making them safer for indoor use and less impactful on air quality. Plasticizers may contain phthalates or other toxic compounds that pose risks to human health and the environment through leaching and persistence in ecosystems. Choosing tackifiers over plasticizers can enhance your product's environmental profile and reduce potential hazards during handling and disposal.

Future Trends in Tackifier and Plasticizer Technologies

Future trends in tackifier and plasticizer technologies emphasize the development of bio-based and sustainable materials to reduce environmental impact while maintaining performance. Innovations in polymer chemistry enable enhanced compatibility and improved mechanical properties, addressing industry demands for safer, non-toxic additives in adhesives and plastics. Advanced formulations focus on increasing thermal stability and durability, supporting applications in automotive, packaging, and electronics sectors.

Tackifier vs Plasticizer Infographic

libmatt.com

libmatt.com