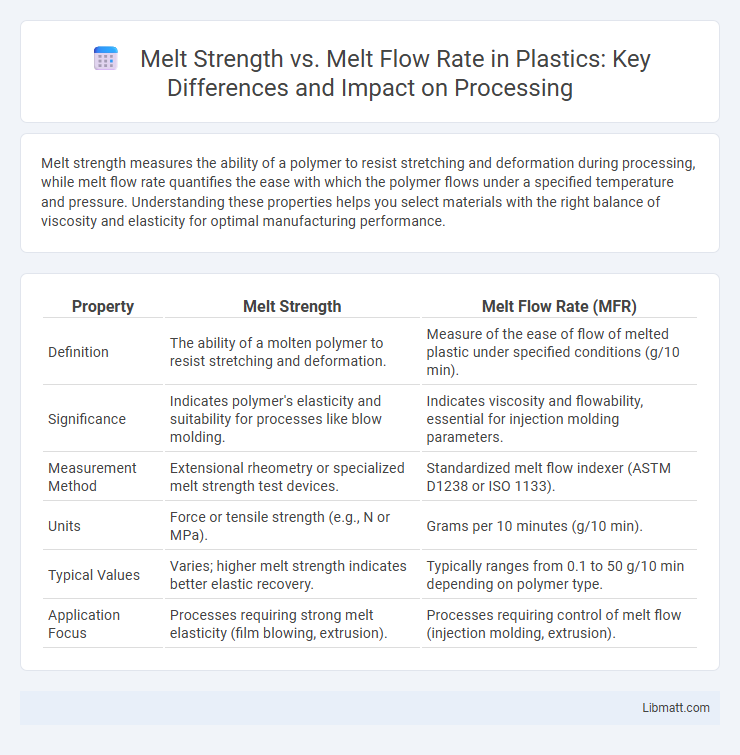

Melt strength measures the ability of a polymer to resist stretching and deformation during processing, while melt flow rate quantifies the ease with which the polymer flows under a specified temperature and pressure. Understanding these properties helps you select materials with the right balance of viscosity and elasticity for optimal manufacturing performance.

Table of Comparison

| Property | Melt Strength | Melt Flow Rate (MFR) |

|---|---|---|

| Definition | The ability of a molten polymer to resist stretching and deformation. | Measure of the ease of flow of melted plastic under specified conditions (g/10 min). |

| Significance | Indicates polymer's elasticity and suitability for processes like blow molding. | Indicates viscosity and flowability, essential for injection molding parameters. |

| Measurement Method | Extensional rheometry or specialized melt strength test devices. | Standardized melt flow indexer (ASTM D1238 or ISO 1133). |

| Units | Force or tensile strength (e.g., N or MPa). | Grams per 10 minutes (g/10 min). |

| Typical Values | Varies; higher melt strength indicates better elastic recovery. | Typically ranges from 0.1 to 50 g/10 min depending on polymer type. |

| Application Focus | Processes requiring strong melt elasticity (film blowing, extrusion). | Processes requiring control of melt flow (injection molding, extrusion). |

Introduction to Melt Strength and Melt Flow Rate

Melt Strength measures a polymer's ability to resist stretching under heat, crucial for processes like film blowing and extrusion. Melt Flow Rate quantifies the ease of polymer flow under a specific temperature and pressure, indicating viscosity and processability. Understanding both properties helps you optimize polymer selection for manufacturing efficiency and product quality.

Defining Melt Strength: Importance in Polymer Processing

Melt strength refers to the polymer's resistance to deformation and breaking under tensile stress when in a molten state, playing a critical role in polymer processing techniques like extrusion and blow molding. High melt strength ensures stable shaping and prevents defects such as sagging or uneven thickness, directly impacting the quality and performance of the final product. Understanding your material's melt strength helps optimize processing parameters and achieve consistent results.

What is Melt Flow Rate? Key Characteristics

Melt Flow Rate (MFR) measures the ease of flow of melted thermoplastic materials under specific conditions, expressed in grams per 10 minutes. Key characteristics include its dependency on temperature and load, providing insight into polymer viscosity, processability, and molecular weight distribution. Your understanding of MFR helps optimize manufacturing processes like injection molding and extrusion by predicting how the material will behave during melting.

Relationship Between Melt Strength and Melt Flow Rate

Melt strength inversely correlates with melt flow rate, where a higher melt flow rate typically indicates lower melt strength due to reduced polymer chain entanglement. Polymers with high melt strength exhibit greater elasticity and resistance to deformation during processing, essential for applications like film blowing or extrusion. Understanding this relationship aids in selecting materials tailored to specific manufacturing processes requiring balanced flowability and mechanical stability.

Factors Affecting Melt Strength in Polymers

Melt strength in polymers is influenced by molecular weight, polymer branching, and temperature, where higher molecular weight and increased branching typically enhance the melt strength by improving chain entanglement. Temperature affects viscosity and flexibility, with elevated temperatures reducing melt strength due to decreased intermolecular forces. Processing conditions such as shear rate and cooling rate also impact melt strength by altering the polymer's microstructure and crystallinity.

Variables Influencing Melt Flow Rate

Melt Flow Rate (MFR) is influenced by variables such as temperature, applied pressure, and polymer molecular weight. Higher temperatures decrease polymer viscosity, increasing the MFR, while elevated molecular weight polymers exhibit lower MFR due to longer chain entanglements. Additionally, screw speed and material additives also impact the measured melt flow rate, affecting polymer processing and end-use performance.

Applications Requiring High Melt Strength

Applications requiring high melt strength, such as blow molding, thermoforming, and film extrusion, demand polymers that can withstand stretching without breaking. High melt strength ensures better bubble stability and uniform wall thickness in blown films, enhancing product durability and clarity. Materials like polypropylene and polyethylene are often selected for these uses due to their superior melt elasticity and controlled melt flow rates.

Applications Leveraging Melt Flow Rate

Melt Flow Rate (MFR) is crucial in applications such as injection molding and extrusion where precise flow characteristics determine part quality and processing speed. High MFR resins enable faster cycle times and finer detail in complex geometries, making them ideal for thin-walled containers and intricate automotive components. Low MFR materials provide better mechanical strength, suitable for blow molding and large structural parts requiring enhanced durability.

Measuring Techniques: Melt Strength vs. Melt Flow Rate

Melt strength is measured using extensional rheometers that stretch a polymer melt to evaluate its resistance to deformation under tensile stress. Melt flow rate (MFR) is determined by extruding a polymer melt through a standardized capillary die under a specified load and recording the mass of polymer flow per unit time, typically expressed in grams per 10 minutes. These contrasting measuring techniques provide critical insights into a polymer's viscoelastic behavior and processability, with melt strength focusing on tensile properties and melt flow rate emphasizing viscosity under shear conditions.

Choosing the Right Property for Your Application

Melt strength indicates a polymer's ability to maintain its structure during processing, crucial for applications requiring form stability such as blow molding or film extrusion. Melt flow rate (MFR) measures the ease of polymer flow under specific conditions, helping to predict processing speed and suitability for injection molding or extrusion. Selecting the right property depends on balancing melt strength for structural integrity and melt flow rate for processing efficiency tailored to the specific manufacturing method.

Melt Strength vs Melt Flow Rate Infographic

libmatt.com

libmatt.com