Microcellular foam injection molding reduces material usage and cycle times by introducing tiny gas bubbles into the polymer, resulting in lighter, stronger parts with improved dimensional stability compared to conventional foam molding. Your production efficiency benefits from enhanced mechanical properties and lower warpage, making microcellular foam a superior choice for complex or high-performance applications.

Table of Comparison

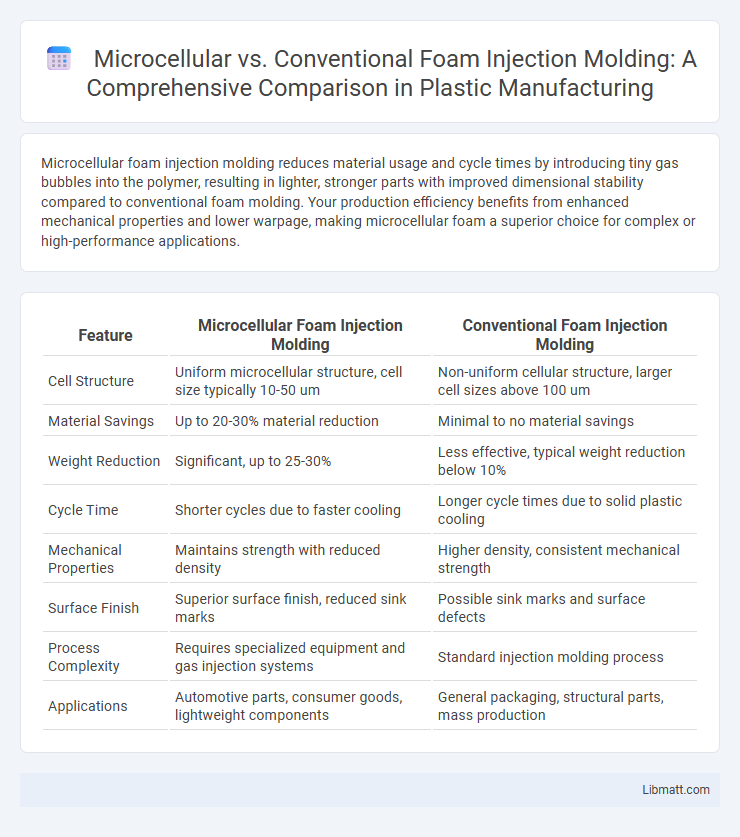

| Feature | Microcellular Foam Injection Molding | Conventional Foam Injection Molding |

|---|---|---|

| Cell Structure | Uniform microcellular structure, cell size typically 10-50 um | Non-uniform cellular structure, larger cell sizes above 100 um |

| Material Savings | Up to 20-30% material reduction | Minimal to no material savings |

| Weight Reduction | Significant, up to 25-30% | Less effective, typical weight reduction below 10% |

| Cycle Time | Shorter cycles due to faster cooling | Longer cycle times due to solid plastic cooling |

| Mechanical Properties | Maintains strength with reduced density | Higher density, consistent mechanical strength |

| Surface Finish | Superior surface finish, reduced sink marks | Possible sink marks and surface defects |

| Process Complexity | Requires specialized equipment and gas injection systems | Standard injection molding process |

| Applications | Automotive parts, consumer goods, lightweight components | General packaging, structural parts, mass production |

Introduction to Foam Injection Molding

Foam injection molding is a manufacturing process that introduces gas or chemical foaming agents into the molten plastic to create lightweight, cellular structures. Microcellular foam injection molding produces ultra-fine cells typically less than 50 microns, resulting in improved material properties such as enhanced strength-to-weight ratio, reduced warpage, and better surface finish compared to conventional foam molding with larger cells. You can benefit from microcellular foam techniques by achieving higher product performance and material savings in applications requiring precision and durability.

Overview of Microcellular Injection Molding

Microcellular injection molding uses a polymer and gas mixture to create fine, uniformly distributed cells within the molded part, reducing material usage and weight without compromising structural integrity. This process improves thermal insulation, dimensional stability, and surface finish compared to conventional foam injection molding, which relies on larger, less uniform bubbles. Your manufacturing can benefit from enhanced cycle times and lower costs with the precise microcellular technology.

Conventional Foam Injection Molding Explained

Conventional foam injection molding involves injecting a polymer melt mixed with a physical or chemical blowing agent into a mold, where it expands to form a cellular core and solid outer skin. This process enhances material properties such as reduced weight and improved dimensional stability while maintaining structural integrity. You can achieve cost-effective production with better insulation and reduced cycle times compared to solid injection molding.

Key Differences Between Microcellular and Conventional Methods

Microcellular foam injection molding uses nitrogen or carbon dioxide to create tiny, uniform cells within the polymer, resulting in lightweight parts with improved dimensional stability and reduced material usage compared to conventional foam molding. Conventional injection molding produces solid parts without internal cell structures, leading to higher material costs and increased weight. Your choice between these methods impacts product strength, cycle time, and environmental sustainability.

Material Selection and Compatibility

Microcellular foam injection molding uses materials with nucleating agents or specialized grades of polymers like ABS, PC, or PPS to enable uniform cell formation, whereas conventional foam molding often relies on standard polymers susceptible to variable expansion. Material selection in microcellular processes requires compatibility with supercritical fluids such as nitrogen or CO2, which act as physical foaming agents to create precisely controlled microcells. Conventional foam injection molding materials prioritize thermal stability and flow properties to accommodate chemical blowing agents, making them less compatible with the low-density, fine-cell structures produced in microcellular molding.

Processing Techniques and Parameters

Microcellular foam injection molding utilizes advanced nucleation and cell growth control to create uniform microcells, reducing material density and warpage compared to conventional foam injection molding which relies on traditional melt and pressure control parameters. Processing parameters such as injection speed, melt temperature, and the use of physical or chemical foaming agents are precisely adjusted in microcellular molding to optimize cell size and distribution, while conventional methods focus mainly on maintaining steady melt flow and cooling rates. Your production efficiency can improve with microcellular foam injection molding due to shorter cycle times and reduced material usage driven by these enhanced processing techniques.

Surface Quality and Part Properties

Microcellular foam injection molding produces parts with finer surface finishes and reduced sink marks compared to conventional foam molding, enhancing aesthetic quality and dimensional stability. The microcellular process introduces uniform microcells within the polymer matrix, resulting in lighter parts with improved impact resistance and reduced warpage. Your choice between these methods should consider the specific surface quality requirements and mechanical property demands of the final application.

Environmental and Cost Considerations

Microcellular foam injection molding reduces material usage by incorporating tiny gas bubbles, significantly lowering raw material costs and decreasing environmental impact through less plastic consumption and reduced weight, which leads to energy savings in transportation. Conventional foam injection molding often requires more polymer and energy, increasing costs and carbon footprint due to denser products and longer cooling times. Your choice of microcellular technology enhances sustainability while optimizing production expenses, making it ideal for eco-conscious and cost-sensitive manufacturing.

Common Applications and Industries

Microcellular foam injection molding is widely utilized in automotive components, electronics housings, and medical device casings due to its lightweight and high-strength properties. Conventional foam injection molding finds common applications in packaging materials, consumer goods, and insulation products, where cost-effectiveness and structural integrity are essential. You can optimize production efficiency and material usage by selecting the appropriate foam molding technique based on industry-specific requirements.

Future Trends in Foam Injection Molding

Future trends in foam injection molding emphasize increased adoption of microcellular foaming technology due to its ability to reduce material usage and enhance product strength without sacrificing quality. Advances in smart process controls and sustainable materials are set to optimize cycle times and reduce environmental impact, making foam injection molding more efficient and eco-friendly. Your manufacturing processes can benefit from integrating these innovations to stay competitive in a market demanding lightweight, durable, and sustainable plastic components.

Microcellular vs Conventional Foam Injection Molding Infographic

libmatt.com

libmatt.com