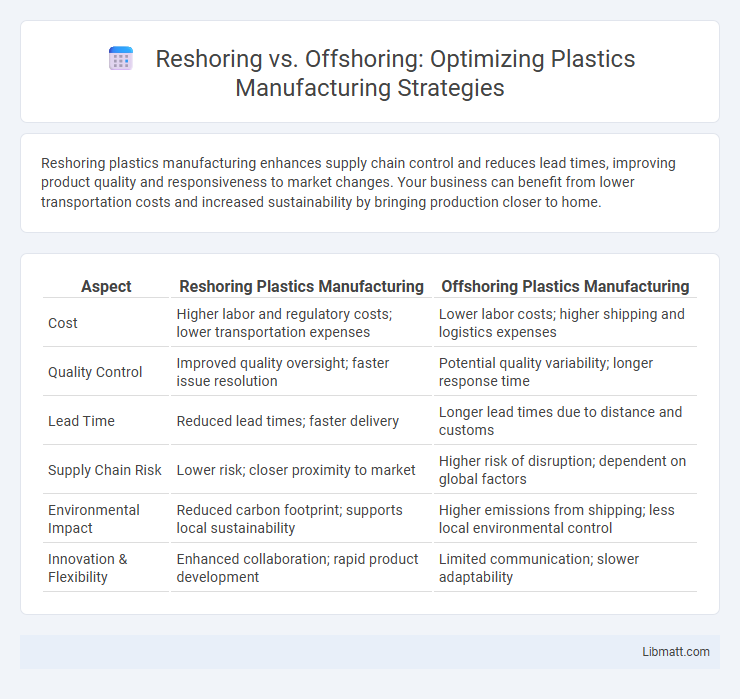

Reshoring plastics manufacturing enhances supply chain control and reduces lead times, improving product quality and responsiveness to market changes. Your business can benefit from lower transportation costs and increased sustainability by bringing production closer to home.

Table of Comparison

| Aspect | Reshoring Plastics Manufacturing | Offshoring Plastics Manufacturing |

|---|---|---|

| Cost | Higher labor and regulatory costs; lower transportation expenses | Lower labor costs; higher shipping and logistics expenses |

| Quality Control | Improved quality oversight; faster issue resolution | Potential quality variability; longer response time |

| Lead Time | Reduced lead times; faster delivery | Longer lead times due to distance and customs |

| Supply Chain Risk | Lower risk; closer proximity to market | Higher risk of disruption; dependent on global factors |

| Environmental Impact | Reduced carbon footprint; supports local sustainability | Higher emissions from shipping; less local environmental control |

| Innovation & Flexibility | Enhanced collaboration; rapid product development | Limited communication; slower adaptability |

Introduction to Plastics Manufacturing Strategies

Plastics manufacturing strategies encompass reshoring and offshoring as primary approaches to optimize production efficiency and cost. Reshoring involves relocating manufacturing operations back to the domestic market to enhance supply chain control, reduce lead times, and support local economies. Offshoring focuses on producing plastics in countries with lower labor and operational costs, leveraging global resource availability and economies of scale to maximize profitability.

Defining Reshoring and Offshoring in Manufacturing

Reshoring in plastics manufacturing refers to the process of bringing production operations back to the company's original country, aiming to enhance supply chain control, reduce lead times, and improve quality assurance. Offshoring involves relocating manufacturing processes to foreign countries, typically to capitalize on lower labor costs, favorable trade policies, and access to emerging markets. Both strategies impact cost structures, logistical complexities, and competitive positioning within the global plastics industry.

Key Drivers Behind Reshoring Plastics Production

Rising transportation costs, supply chain disruptions, and increasing demand for faster product delivery are key drivers behind reshoring plastics manufacturing. Advances in automation and increased focus on sustainability encourage companies to bring production closer to their customer base. You can benefit from improved quality control and reduced environmental impact by choosing reshoring for your plastics production.

Advantages of Offshoring Plastics Manufacturing

Offshoring plastics manufacturing offers significant cost savings due to lower labor and production expenses in countries with cheaper workforce and materials. Access to specialized expertise and advanced manufacturing technologies in established offshore hubs enhances product quality and innovation. Furthermore, offshoring allows companies to scale production quickly and enter emerging international markets more effectively, boosting global supply chain flexibility.

Cost Analysis: Reshoring vs Offshoring

Reshoring plastics manufacturing often reduces transportation expenses, import tariffs, and supply chain disruptions, leading to more predictable overall costs compared to offshoring. Offshoring may offer lower labor rates but incurs hidden expenses such as longer lead times, quality control challenges, and increased inventory carrying costs. Your cost analysis should weigh these factors alongside potential risks to determine the most financially viable manufacturing strategy.

Supply Chain Resilience and Risk Management

Reshoring plastics manufacturing enhances supply chain resilience by reducing dependency on distant suppliers and minimizing lead times, which ensures quicker response to market fluctuations and disruptions. Offshoring, while cost-effective, exposes your supply chain to risks such as geopolitical tensions, transportation delays, and quality control challenges. Prioritizing reshoring can significantly strengthen risk management strategies by improving oversight and fostering closer collaboration with manufacturers.

Impacts on Quality Control and Product Innovation

Reshoring plastics manufacturing enhances quality control by enabling closer oversight, reducing defects, and facilitating rapid adjustments in production processes. Proximity to research and development teams accelerates product innovation, allowing manufacturers to respond swiftly to market demands and integrate advanced materials or technologies. Offshoring often risks communication delays and inconsistent quality standards, hindering innovation and increasing the likelihood of production errors.

Environmental and Sustainability Considerations

Reshoring plastics manufacturing reduces carbon emissions and transportation-related pollution by shortening supply chains, enhancing your company's environmental footprint. Offshoring often relies on regions with less stringent environmental regulations, increasing risks of pollution and waste mismanagement. Prioritizing reshoring supports sustainable practices, regulatory compliance, and improves your brand's commitment to eco-friendly manufacturing.

Workforce and Skills Implications

Reshoring plastics manufacturing requires investing in advanced workforce training to address skill gaps in automation and sustainable production technologies. Offshoring often offers access to lower labor costs but may compromise quality control and lead to challenges in managing skilled labor standards remotely. Companies must weigh the benefits of a highly skilled domestic workforce against the cost advantages of international labor markets when deciding between reshoring and offshoring.

Future Trends in Global Plastics Manufacturing

Future trends in global plastics manufacturing indicate a growing preference for reshoring due to rising labor costs and supply chain disruptions in offshore locations. Advances in automation and sustainable technologies are enabling manufacturers to reduce production costs and environmental impact domestically. Market demand for faster delivery times and compliance with stringent environmental regulations further drive the shift towards reshoring plastics manufacturing.

Reshoring vs Offshoring Plastics Manufacturing Infographic

libmatt.com

libmatt.com