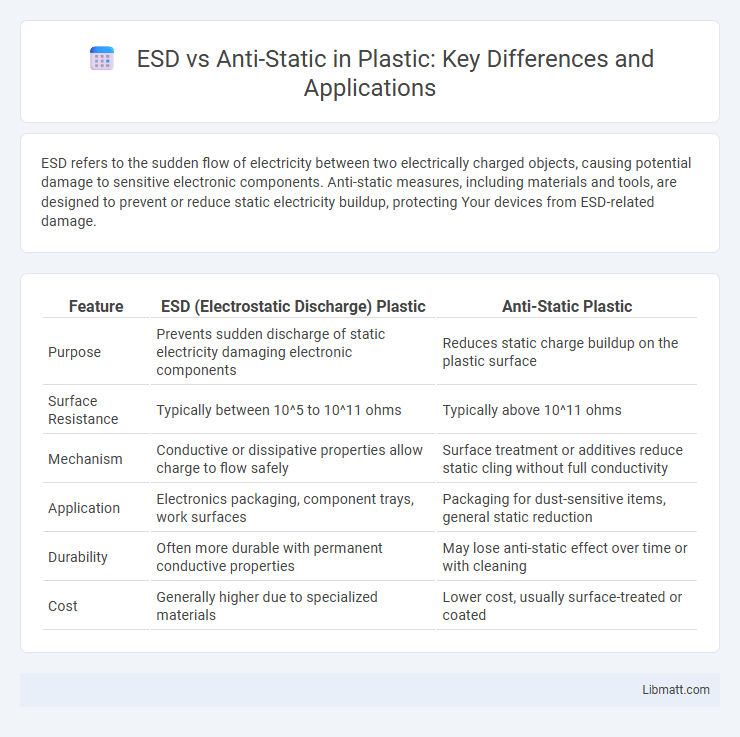

ESD refers to the sudden flow of electricity between two electrically charged objects, causing potential damage to sensitive electronic components. Anti-static measures, including materials and tools, are designed to prevent or reduce static electricity buildup, protecting Your devices from ESD-related damage.

Table of Comparison

| Feature | ESD (Electrostatic Discharge) Plastic | Anti-Static Plastic |

|---|---|---|

| Purpose | Prevents sudden discharge of static electricity damaging electronic components | Reduces static charge buildup on the plastic surface |

| Surface Resistance | Typically between 10^5 to 10^11 ohms | Typically above 10^11 ohms |

| Mechanism | Conductive or dissipative properties allow charge to flow safely | Surface treatment or additives reduce static cling without full conductivity |

| Application | Electronics packaging, component trays, work surfaces | Packaging for dust-sensitive items, general static reduction |

| Durability | Often more durable with permanent conductive properties | May lose anti-static effect over time or with cleaning |

| Cost | Generally higher due to specialized materials | Lower cost, usually surface-treated or coated |

Understanding ESD and Anti-Static: Key Definitions

ESD (Electrostatic Discharge) refers to the sudden flow of electricity between two electrically charged objects, which can damage sensitive electronic components. Anti-static describes materials or measures designed to prevent the buildup of static electricity, minimizing the risk of ESD. Understanding these key definitions helps you protect electronic devices and maintain their longevity in environments prone to static electricity.

How ESD and Anti-Static Concepts Differ

ESD (Electrostatic Discharge) refers to the sudden flow of electricity between two electrically charged objects, which can damage sensitive electronic components. Anti-static measures involve techniques or materials designed to prevent the buildup of static electricity, reducing the risk of ESD events. Understanding the difference helps you implement appropriate solutions to protect devices from electrostatic damage effectively.

The Science Behind Electrostatic Discharge (ESD)

Electrostatic Discharge (ESD) occurs when two objects with different electrical potentials come into contact, causing a sudden flow of electricity that can damage sensitive electronic components. The science behind ESD involves the buildup of static electricity through contact and separation of materials, leading to an imbalance of charges that seeks to equalize quickly. Understanding ESD is crucial for implementing anti-static measures that protect your devices from unexpected electrical surges.

Anti-Static Solutions: Materials and Methods

Anti-static solutions involve materials designed to reduce or eliminate static electricity build-up, including conductive polymers, carbon-loaded plastics, and metal-coated fabrics that safely dissipate charges. Common methods use ionizing bars, anti-static sprays, and grounding techniques to prevent electrostatic discharge (ESD) that can damage sensitive electronics. Your workspace can benefit from these materials and methods by minimizing static risks through controlled humidity, proper grounding, and the use of anti-static mats or wrist straps.

ESD Protection: Components and Practices

ESD protection involves the use of specialized components such as transient voltage suppressors (TVS), electrostatic discharge diodes, and grounding wrist straps to prevent damage caused by electrostatic discharge events. Key practices include proper grounding techniques, the use of conductive mats, and controlled humidity environments to minimize static buildup and safely dissipate charge. Implementing ESD-safe workstations and packaging materials is critical to maintaining the integrity of sensitive electronic components during handling and assembly.

Common Applications of ESD and Anti-Static Measures

ESD (Electrostatic Discharge) and anti-static measures are critical in electronics manufacturing, semiconductor production, and cleanroom environments where static charge can damage sensitive components. Common applications include using ESD wrist straps, mats, and ionizers to neutralize static electricity during assembly and testing of circuit boards and microchips. In semiconductor fabs and data centers, anti-static flooring and packaging materials help prevent electrostatic buildup, ensuring device reliability and longevity.

Risks and Consequences of ESD Events

Electrostatic discharge (ESD) events pose significant risks including damage to sensitive electronic components, leading to device malfunction or complete failure. The consequences of ESD can result in costly repairs, data loss, and reduced product reliability in industries such as semiconductor manufacturing and electronics assembly. Effective anti-static measures are essential to minimize static buildup and prevent ESD occurrences that compromise equipment performance and safety.

Choosing Between ESD and Anti-Static Products

When choosing between ESD and anti-static products, prioritize ESD protection for environments with sensitive electronic components, as these products actively dissipate electrostatic charges to prevent damage. Anti-static products reduce static buildup but do not control the discharge, making them suitable for less sensitive applications where static prevention is sufficient. Understanding the required level of static control in specific settings guides the selection of appropriate materials such as ESD flooring, wrist straps, or anti-static packaging.

Industry Standards and Compliance for ESD Safety

Industry standards such as ANSI/ESD S20.20 and IEC 61340-5-1 establish stringent guidelines for ESD control to ensure product safety and reliability in electronic manufacturing. Compliance with these standards involves implementing comprehensive ESD prevention programs, including proper grounding, use of ESD-safe materials, and regular employee training. Your adherence to recognized standards minimizes risk of electrostatic discharge damage, safeguarding sensitive components throughout production and handling processes.

Best Practices for ESD and Anti-Static Management

Effective ESD and anti-static management involves grounding personnel and equipment, using ESD-safe work surfaces, and implementing humidity control to reduce static charge buildup. Regular training on proper handling of sensitive components and use of personal protective equipment such as wrist straps and heel grounders ensure compliance with ESD control standards like ANSI/ESD S20.20. Monitoring tools like static field meters and ionizers further enhance protection by neutralizing static charges in critical environments.

ESD vs Anti-static Infographic

libmatt.com

libmatt.com