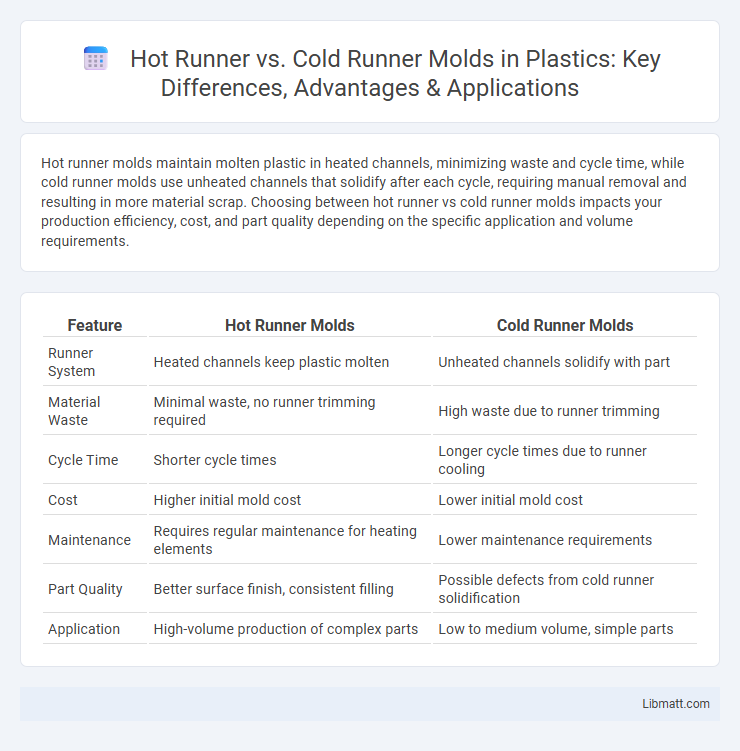

Hot runner molds maintain molten plastic in heated channels, minimizing waste and cycle time, while cold runner molds use unheated channels that solidify after each cycle, requiring manual removal and resulting in more material scrap. Choosing between hot runner vs cold runner molds impacts your production efficiency, cost, and part quality depending on the specific application and volume requirements.

Table of Comparison

| Feature | Hot Runner Molds | Cold Runner Molds |

|---|---|---|

| Runner System | Heated channels keep plastic molten | Unheated channels solidify with part |

| Material Waste | Minimal waste, no runner trimming required | High waste due to runner trimming |

| Cycle Time | Shorter cycle times | Longer cycle times due to runner cooling |

| Cost | Higher initial mold cost | Lower initial mold cost |

| Maintenance | Requires regular maintenance for heating elements | Lower maintenance requirements |

| Part Quality | Better surface finish, consistent filling | Possible defects from cold runner solidification |

| Application | High-volume production of complex parts | Low to medium volume, simple parts |

Introduction to Runner Systems in Injection Molding

Runner systems in injection molding channel molten plastic from the injection unit to the mold cavities, crucially affecting cycle time, material usage, and product quality. Hot runner molds feature heated channels that keep the plastic in a molten state, minimizing waste and improving cycle efficiency. Cold runner molds use unheated channels where the plastic solidifies, often requiring post-cycle removal and recycling of runner scraps.

What is a Hot Runner Mold?

A Hot Runner Mold is an injection molding system that uses heated components to keep the plastic in a molten state within the mold's runner, eliminating waste and reducing cycle times. This technology enhances precision and efficiency by delivering consistent melt flow directly into the mold cavities. Your manufacturing process benefits from reduced material usage and improved product quality with a Hot Runner Mold.

What is a Cold Runner Mold?

A Cold Runner Mold features a channel system that cools and solidifies the plastic before ejecting it as a separate piece, unlike hot runner molds that keep the plastic molten. This type of mold offers cost-effective tooling, easier maintenance, and lower upfront investment, making it suitable for short production runs or prototyping. Your choice of cold runner mold can significantly impact waste management and cycle time efficiency in injection molding processes.

Key Differences Between Hot and Cold Runner Molds

Hot runner molds maintain molten plastic within heated channels, enabling faster cycles and reduced waste, while cold runner molds use unheated channels that solidify along with the part, increasing material waste and cycle time. Hot runner systems offer more precise temperature control for improved part quality and less post-processing, whereas cold runner molds are simpler and less expensive but less efficient for high-volume production. You can optimize manufacturing efficiency and product consistency by selecting the appropriate runner system based on your production scale and material requirements.

Advantages of Hot Runner Molds

Hot runner molds enhance production efficiency by significantly reducing material waste and cycle times compared to cold runner systems. They provide superior temperature control and consistent melt flow, resulting in higher-quality parts with improved surface finishes. The ability to eliminate runner scrap also lowers overall manufacturing costs and supports sustainable production processes.

Advantages of Cold Runner Molds

Cold runner molds offer the advantage of lower initial tooling costs compared to hot runner systems, making them ideal for small production runs or prototyping. These molds provide greater flexibility in material selection and ease of maintenance since there are no complex heating elements involved. Additionally, cold runner molds eliminate the risk of material degradation caused by prolonged exposure to heat, ensuring consistent part quality.

Disadvantages of Hot Runner Molds

Hot runner molds present challenges such as higher initial investment costs and increased maintenance complexity due to intricate heating systems. Their thermal management requires precise control to prevent material degradation, which can lead to inconsistent part quality. You may also face longer setup times and potential difficulties in troubleshooting compared to cold runner molds.

Disadvantages of Cold Runner Molds

Cold runner molds present challenges such as increased material waste due to the need to trim and recycle solidified runners, leading to higher production costs. They often cause longer cycle times because of the cooling and removal process of the runners, reducing overall efficiency. Your production may also face limitations in design flexibility and potential inconsistencies in part quality compared to hot runner systems.

Applications Suited for Each Runner System

Hot runner molds are ideal for complex, high-volume plastic injection molding applications requiring intricate designs and minimal waste, such as automotive components, medical devices, and consumer electronics. Cold runner molds suit simpler, low-to-medium volume production where cost efficiency and ease of maintenance matter, commonly used for packaging, toys, and household items. Your choice depends on production scale, part complexity, and budget constraints to ensure optimal manufacturing efficiency.

How to Choose Between Hot Runner and Cold Runner Molds

Choosing between hot runner and cold runner molds depends on factors like production volume, material type, and cost efficiency. Hot runner molds reduce waste and cycle times, making them ideal for high-volume manufacturing and complex parts, while cold runner molds offer lower initial costs and simpler maintenance for smaller production runs. Consider the balance between upfront investment and long-term savings based on specific project requirements and budget constraints.

Hot Runner vs Cold Runner Molds Infographic

libmatt.com

libmatt.com