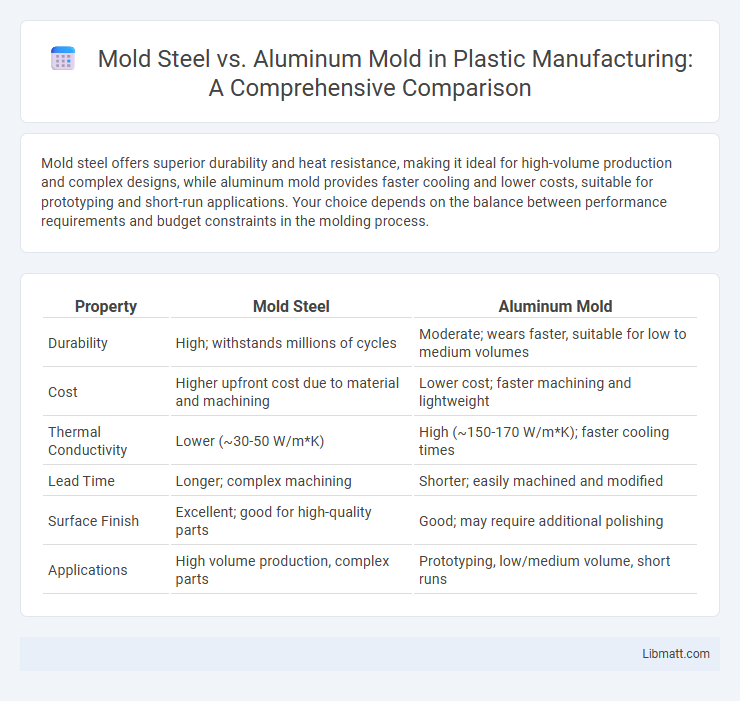

Mold steel offers superior durability and heat resistance, making it ideal for high-volume production and complex designs, while aluminum mold provides faster cooling and lower costs, suitable for prototyping and short-run applications. Your choice depends on the balance between performance requirements and budget constraints in the molding process.

Table of Comparison

| Property | Mold Steel | Aluminum Mold |

|---|---|---|

| Durability | High; withstands millions of cycles | Moderate; wears faster, suitable for low to medium volumes |

| Cost | Higher upfront cost due to material and machining | Lower cost; faster machining and lightweight |

| Thermal Conductivity | Lower (~30-50 W/m*K) | High (~150-170 W/m*K); faster cooling times |

| Lead Time | Longer; complex machining | Shorter; easily machined and modified |

| Surface Finish | Excellent; good for high-quality parts | Good; may require additional polishing |

| Applications | High volume production, complex parts | Prototyping, low/medium volume, short runs |

Introduction to Mold Steel and Aluminum Mold

Mold steel offers superior durability, high wear resistance, and excellent dimensional stability, making it ideal for high-volume injection molding applications requiring precision and longevity. Aluminum molds excel in rapid prototyping and low-volume production due to their lightweight nature and faster heat dissipation, enabling shorter cycle times and lower initial costs. Both materials serve specific manufacturing needs; mold steel suits complex, long-run mold production, while aluminum provides cost-effective solutions for quicker turnaround and less demanding molds.

Material Properties: Steel vs Aluminum

Steel molds offer superior hardness and wear resistance, making them ideal for high-volume production requiring durability and precision. Aluminum molds provide excellent thermal conductivity and lightweight properties, which reduce cycle times and improve cooling efficiency but are less durable under heavy stress. Your choice depends on balancing these material properties with production demands and budget constraints.

Durability and Lifespan Comparison

Mold steel offers superior durability and a longer lifespan compared to aluminum molds, making it ideal for high-volume production runs and complex parts. Aluminum molds wear faster due to their softer nature, which can lead to increased maintenance and shorter overall service life. Your choice should consider production scale and budget, as mold steel ensures consistent performance and longevity under demanding manufacturing conditions.

Cost Differences in Mold Manufacturing

Mold steel typically incurs higher costs in mold manufacturing due to its superior durability, heat resistance, and longevity, which extend the tool's life and reduce long-term maintenance expenses. Aluminum molds are less expensive initially because of lower material and machining costs, making them ideal for short production runs or prototyping. Your choice between mold steel and aluminum will depend on budget constraints and production volume requirements, balancing upfront investment against overall mold performance and lifespan.

Cycle Time and Production Speed

Mold steel offers superior durability and can withstand higher injection pressures, enabling faster cycle times and more consistent production speed in high-volume manufacturing. Aluminum molds provide faster initial cooling, reducing cycle time for short-run or prototype production but wear out quicker under continuous high-speed use. Choosing mold steel improves long-term production efficiency, while aluminum molds optimize speed for limited runs with less mechanical strain.

Surface Finish and Product Quality

Mold steel provides superior surface finish quality due to its hardness and wear resistance, resulting in products with finer details and smoother textures. Aluminum molds tend to have lower durability, which can lead to quicker surface degradation and reduced product consistency over time. The choice between mold steel and aluminum directly impacts the longevity of surface finish quality and overall product precision in manufacturing.

Maintenance and Repair Considerations

Mold steel requires regular maintenance to prevent corrosion and maintain surface hardness, with repairs often involving specialized welding and heat treatment to restore wear resistance. Aluminum molds offer easier maintenance due to their corrosion-resistant properties but may need more frequent repairs for surface damage or deformation because of lower hardness compared to steel. Choosing between mold steel and aluminum molds depends on balancing repair complexity, maintenance frequency, and the durability demands of the production environment.

Suitable Applications for Steel Molds

Steel molds are ideal for high-volume production runs due to their exceptional durability and resistance to wear, making them suitable for automotive parts, industrial components, and complex injection molding processes. Their superior strength allows them to withstand high-pressure molding conditions and produce consistent, precise parts with intricate details. You benefit from longer mold life and reduced maintenance costs when using steel molds for demanding applications requiring repeated use.

Suitable Applications for Aluminum Molds

Aluminum molds are ideal for short to medium production runs, prototypes, and low-volume manufacturing due to their lightweight and excellent thermal conductivity, which reduces cycle times. These molds are commonly used in automotive parts, consumer electronics, and packaging industries where quick turnaround and cost-efficiency are critical. If your project requires rapid mold production with moderate durability, aluminum molds offer a cost-effective solution with faster heat dissipation compared to mold steel.

Choosing the Right Mold Material for Your Project

Choosing the right mold material between mold steel and aluminum depends on project requirements such as production volume, durability, and cost. Mold steel offers superior strength and wear resistance, making it ideal for high-volume or complex parts, while aluminum molds provide faster heat dissipation and are cost-effective for low to medium production runs. Evaluating factors like cycle time, part complexity, and budget will help determine whether mold steel or aluminum best suits your manufacturing needs.

Mold steel vs aluminum mold Infographic

libmatt.com

libmatt.com