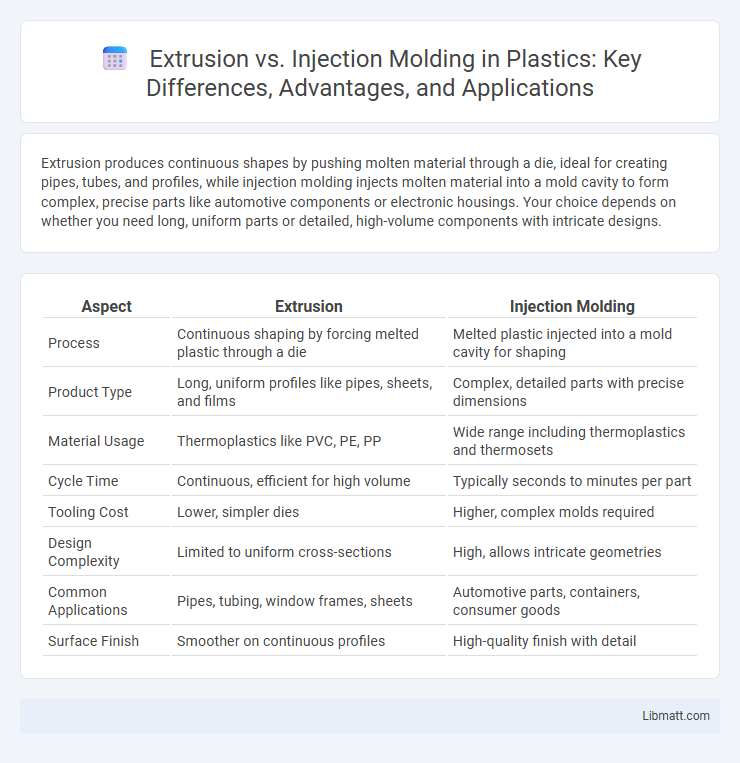

Extrusion produces continuous shapes by pushing molten material through a die, ideal for creating pipes, tubes, and profiles, while injection molding injects molten material into a mold cavity to form complex, precise parts like automotive components or electronic housings. Your choice depends on whether you need long, uniform parts or detailed, high-volume components with intricate designs.

Table of Comparison

| Aspect | Extrusion | Injection Molding |

|---|---|---|

| Process | Continuous shaping by forcing melted plastic through a die | Melted plastic injected into a mold cavity for shaping |

| Product Type | Long, uniform profiles like pipes, sheets, and films | Complex, detailed parts with precise dimensions |

| Material Usage | Thermoplastics like PVC, PE, PP | Wide range including thermoplastics and thermosets |

| Cycle Time | Continuous, efficient for high volume | Typically seconds to minutes per part |

| Tooling Cost | Lower, simpler dies | Higher, complex molds required |

| Design Complexity | Limited to uniform cross-sections | High, allows intricate geometries |

| Common Applications | Pipes, tubing, window frames, sheets | Automotive parts, containers, consumer goods |

| Surface Finish | Smoother on continuous profiles | High-quality finish with detail |

Introduction to Extrusion and Injection Molding

Extrusion is a continuous manufacturing process where molten material is pushed through a shaped die to create long, uniform products like pipes, sheets, or profiles. Injection molding involves injecting molten plastic into a mold cavity to produce complex, detailed parts with high precision and repeatability. Your choice between these methods depends on the required product geometry, production volume, and material properties.

Overview of the Extrusion Process

Extrusion is a manufacturing process where raw plastic material is melted and pushed through a shaped die to create continuous profiles such as pipes, sheets, or films. The process involves feeding thermoplastic pellets into a heated barrel with a rotating screw that melts and homogenizes the material before forcing it through the die opening. Extrusion is ideal for producing consistent cross-sectional products with high volume efficiency and minimal waste.

Overview of the Injection Molding Process

Injection molding is a manufacturing process where molten material, typically plastic, is injected into a mold cavity under high pressure to form precise, complex shapes. The process involves melting the raw material, injecting it into the mold, cooling it quickly, and then ejecting the solidified part for assembly or further processing. Your choice of injection molding ensures high-volume production efficiency with consistent quality and intricate detail replication.

Material Compatibility in Extrusion vs Injection Molding

Extrusion excels with thermoplastics like polyethylene, PVC, and polypropylene, enabling continuous profiles and flexible shapes, while injection molding accommodates a broader range of materials, including thermoplastics, thermosets, and elastomers, for complex, high-precision parts. Your choice depends on the desired product geometry and production volume, with extrusion favoring long, uniform cross-sections and injection molding suited for detailed, multidimensional components. Material viscosity and thermal properties influence processing conditions, making compatibility essential for achieving optimal mechanical and surface characteristics in each method.

Cost Comparison: Extrusion vs Injection Molding

Extrusion generally offers lower initial tooling costs compared to injection molding, making it more cost-effective for producing continuous profiles or large volumes of simpler shapes. Injection molding involves higher upfront expenses for mold fabrication but excels in producing complex, precise, and high-volume parts with consistent quality, which can reduce per-unit costs over time. Overall, extrusion is more economical for long runs of basic shapes, while injection molding is cost-efficient for intricate designs and mass production.

Design Flexibility and Product Complexity

Extrusion offers continuous production of uniform cross-sectional profiles, ideal for simpler designs like tubes and sheets, while injection molding enables intricate geometries with complex details and varying wall thicknesses. Your choice depends on the desired product complexity; injection molding supports higher design flexibility by accommodating varied shapes, undercuts, and embedded components. Extrusion is cost-effective for long, consistent profiles, but injection molding excels when producing highly detailed, customizable parts.

Production Speed and Efficiency

Injection molding typically offers higher production speed for complex, high-precision parts, producing thousands of units quickly due to its rapid cycle times and automation potential. Extrusion excels in continuous production of long, uniform profiles like pipes and sheets, optimizing efficiency for large volumes with minimal material waste. Selecting between extrusion and injection molding depends on part design, required output volume, and cycle time priorities.

Applications and Product Examples

Extrusion is ideal for creating continuous profiles such as pipes, tubing, and window frames, commonly used in construction and packaging industries. Injection molding suits complex, high-precision parts like automotive components, medical devices, and consumer electronics enclosures. Your choice depends on the product's design complexity and production volume requirements, with extrusion favoring long, uniform shapes and injection molding excelling at detailed, intricate items.

Quality Control and Surface Finish

Extrusion consistently delivers uniform product quality with smooth surface finishes due to continuous material flow and controlled cooling processes. Injection molding offers superior precision in intricate designs, ensuring high-quality surface finishes with minimal defects through rigorous quality control measures like mold temperature regulation and automated inspection. Your choice between these methods should consider the specific quality and surface finish demands of your product to achieve optimal results.

Choosing the Right Process for Your Project

Selecting between extrusion and injection molding depends on the project's geometric complexity and production volume requirements. Extrusion is ideal for creating continuous shapes with uniform cross-sections, such as pipes and sheets, offering cost-efficiency in high-volume runs. Injection molding excels in producing intricate, three-dimensional parts with precise detail, suitable for mass-producing components like automotive parts and consumer goods.

Extrusion vs Injection Molding Infographic

libmatt.com

libmatt.com