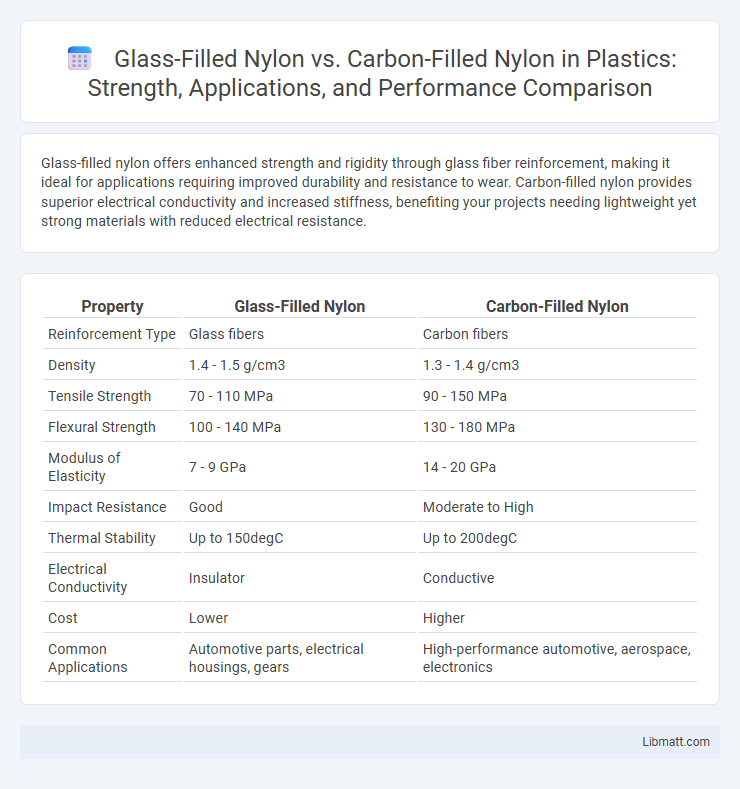

Glass-filled nylon offers enhanced strength and rigidity through glass fiber reinforcement, making it ideal for applications requiring improved durability and resistance to wear. Carbon-filled nylon provides superior electrical conductivity and increased stiffness, benefiting your projects needing lightweight yet strong materials with reduced electrical resistance.

Table of Comparison

| Property | Glass-Filled Nylon | Carbon-Filled Nylon |

|---|---|---|

| Reinforcement Type | Glass fibers | Carbon fibers |

| Density | 1.4 - 1.5 g/cm3 | 1.3 - 1.4 g/cm3 |

| Tensile Strength | 70 - 110 MPa | 90 - 150 MPa |

| Flexural Strength | 100 - 140 MPa | 130 - 180 MPa |

| Modulus of Elasticity | 7 - 9 GPa | 14 - 20 GPa |

| Impact Resistance | Good | Moderate to High |

| Thermal Stability | Up to 150degC | Up to 200degC |

| Electrical Conductivity | Insulator | Conductive |

| Cost | Lower | Higher |

| Common Applications | Automotive parts, electrical housings, gears | High-performance automotive, aerospace, electronics |

Introduction to Glass-Filled Nylon and Carbon-Filled Nylon

Glass-filled nylon enhances standard nylon by incorporating glass fibers, significantly improving strength, stiffness, and thermal stability for demanding engineering applications. Carbon-filled nylon integrates carbon fibers, offering superior electrical conductivity, increased rigidity, and excellent wear resistance, ideal for high-performance mechanical parts. Both materials provide advanced mechanical properties but differ in electrical characteristics and specific use cases within industrial manufacturing.

Composition and Material Properties

Glass-filled nylon consists of nylon resin reinforced with glass fibers, enhancing tensile strength, rigidity, and thermal stability. Carbon-filled nylon incorporates carbon fibers, offering superior strength-to-weight ratio, increased stiffness, and improved electrical conductivity compared to glass-filled variants. Both materials exhibit excellent wear resistance and dimensional stability but differ in mechanical performance and application suitability due to their distinct fiber reinforcements.

Mechanical Strength Comparison

Glass-filled nylon offers enhanced tensile strength and improved stiffness compared to pure nylon, making it suitable for applications requiring moderate mechanical durability. Carbon-filled nylon typically provides superior rigidity and higher strength-to-weight ratio, which benefits components subjected to heavy mechanical stress. Your choice between these materials should consider specific load requirements and the balance between strength and weight in your application.

Weight and Density Differences

Glass-filled nylon offers increased density and weight compared to standard nylon due to its glass fiber inclusion, typically resulting in a density around 1.4 to 1.5 g/cm3. Carbon-filled nylon, while slightly lighter with a density near 1.3 to 1.4 g/cm3, provides superior stiffness and strength for applications where weight savings are critical. Understanding these weight and density differences helps you select the appropriate material for optimized performance and durability in engineering projects.

Thermal Resistance and Performance

Glass-filled nylon exhibits enhanced thermal resistance due to the incorporation of glass fibers, which increases its heat deflection temperature up to approximately 260degC. Carbon-filled nylon surpasses glass-filled variants in thermal stability, offering improved heat dissipation and maintaining mechanical properties at elevated temperatures beyond 280degC. Both materials deliver superior thermal performance compared to unfilled nylon, but carbon-filled nylon is preferred for applications requiring higher thermal endurance and enhanced dimensional stability under heat stress.

Chemical Resistance and Durability

Glass-filled nylon offers excellent chemical resistance to fuels, oils, and solvents, maintaining structural integrity in harsh environments. Carbon-filled nylon enhances durability and mechanical strength, providing superior wear resistance and dimensional stability under heavy loads. Your choice depends on whether chemical resistance or extreme toughness is the priority for your application.

Applications in Industry

Glass-filled nylon is widely used in automotive and electrical industries due to its excellent strength, dimensional stability, and resistance to heat and chemicals. Carbon-filled nylon offers superior stiffness, conductivity, and wear resistance, making it ideal for aerospace, electronics, and high-performance mechanical components. Your choice between glass-filled and carbon-filled nylon should depend on the specific demands of your application, such as electrical conductivity requirements or weight considerations.

Machinability and Processing Considerations

Glass-filled nylon offers enhanced machinability due to its uniform fiber distribution, allowing for precise cutting and shaping with standard machining tools, while carbon-filled nylon typically requires specialized tooling to manage its increased abrasiveness. The processing of glass-filled nylon involves controlled molding temperatures to maintain fiber integrity and reduce wear on equipment, whereas carbon-filled nylon demands higher thermal stability and slower cooldown rates to prevent cracking and ensure consistent mechanical properties. Choosing between these materials necessitates careful consideration of machining tool wear, processing temperatures, and desired surface finish to optimize production efficiency and part performance.

Cost Analysis and Economic Impact

Glass-filled nylon costs significantly less than carbon-filled nylon, making it a more budget-friendly option for large-scale manufacturing. The higher price of carbon-filled nylon is justified by its superior strength, stiffness, and thermal conductivity, which can reduce long-term maintenance and replacement costs. Choosing glass-filled nylon optimizes upfront expenditure, while carbon-filled nylon offers economic benefits through enhanced performance and durability in high-stress applications.

Choosing the Right Material: Key Considerations

Selecting between glass-filled nylon and carbon-filled nylon depends on your application's strength, weight, and thermal requirements. Glass-filled nylon offers enhanced rigidity and excellent resistance to wear, ideal for high-impact uses, while carbon-filled nylon provides superior stiffness with reduced weight and improved electrical conductivity for precision components. Evaluating these material properties helps you optimize performance and durability in your manufacturing process.

Glass-Filled Nylon vs Carbon-Filled Nylon Infographic

libmatt.com

libmatt.com