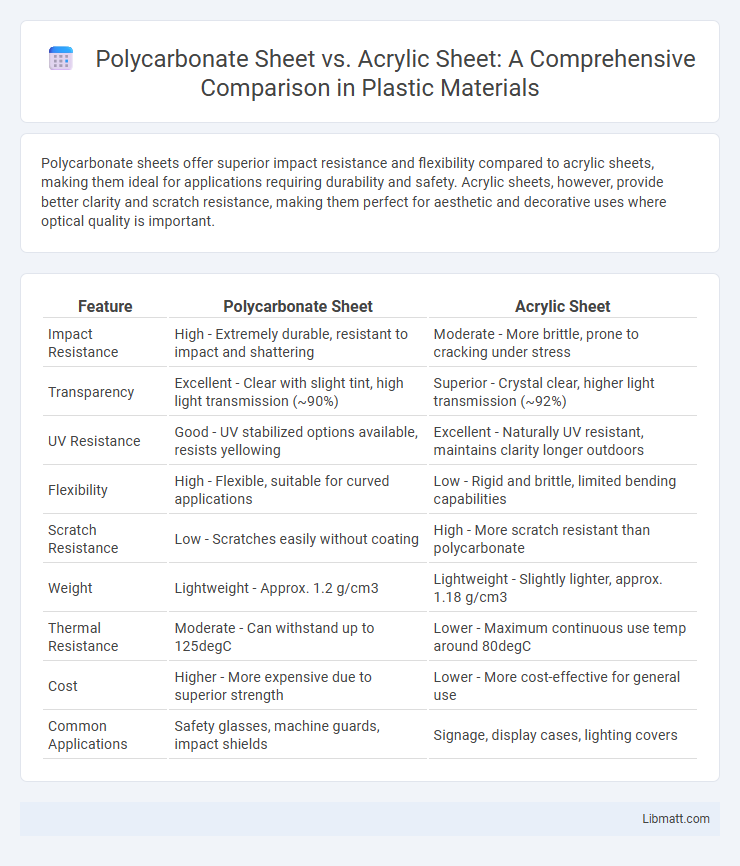

Polycarbonate sheets offer superior impact resistance and flexibility compared to acrylic sheets, making them ideal for applications requiring durability and safety. Acrylic sheets, however, provide better clarity and scratch resistance, making them perfect for aesthetic and decorative uses where optical quality is important.

Table of Comparison

| Feature | Polycarbonate Sheet | Acrylic Sheet |

|---|---|---|

| Impact Resistance | High - Extremely durable, resistant to impact and shattering | Moderate - More brittle, prone to cracking under stress |

| Transparency | Excellent - Clear with slight tint, high light transmission (~90%) | Superior - Crystal clear, higher light transmission (~92%) |

| UV Resistance | Good - UV stabilized options available, resists yellowing | Excellent - Naturally UV resistant, maintains clarity longer outdoors |

| Flexibility | High - Flexible, suitable for curved applications | Low - Rigid and brittle, limited bending capabilities |

| Scratch Resistance | Low - Scratches easily without coating | High - More scratch resistant than polycarbonate |

| Weight | Lightweight - Approx. 1.2 g/cm3 | Lightweight - Slightly lighter, approx. 1.18 g/cm3 |

| Thermal Resistance | Moderate - Can withstand up to 125degC | Lower - Maximum continuous use temp around 80degC |

| Cost | Higher - More expensive due to superior strength | Lower - More cost-effective for general use |

| Common Applications | Safety glasses, machine guards, impact shields | Signage, display cases, lighting covers |

Introduction to Polycarbonate and Acrylic Sheets

Polycarbonate sheets are known for their exceptional impact resistance and optical clarity, making them ideal for applications requiring durability and transparency. Acrylic sheets offer excellent weather resistance and clarity while being lightweight and cost-effective for various decorative and protective uses. Understanding these distinct properties helps you choose the right material for construction, signage, or glazing projects.

Material Composition and Properties

Polycarbonate sheets are made from polymerized bisphenol A and exhibit high impact resistance, superior UV protection, and excellent thermal stability compared to acrylic sheets, which consist of polymethyl methacrylate (PMMA) with higher clarity but lower fracture toughness. Polycarbonate's molecular structure provides flexibility and durability under stress, making it ideal for safety applications, whereas acrylic offers better optical clarity and scratch resistance, suitable for display and glazing purposes. The choice between polycarbonate and acrylic depends largely on the intended use, balancing factors like strength, transparency, weather resistance, and cost-effectiveness.

Strength and Impact Resistance Comparison

Polycarbonate sheets offer superior strength and impact resistance compared to acrylic sheets, with the ability to withstand impacts up to 250 times greater than glass. Acrylic sheets, while more rigid and scratch-resistant, are more prone to cracking or shattering under heavy impact. Choosing polycarbonate ensures your application benefits from enhanced durability and safety in high-stress environments.

Optical Clarity and Light Transmission

Polycarbonate sheets typically offer high impact resistance but slightly lower optical clarity compared to acrylic sheets, which are known for their superior transparency and excellent light transmission rates up to 92%. Acrylic sheets maintain better clarity over time without yellowing, making them ideal for applications requiring consistent visual performance. Polycarbonate's light transmission usually ranges around 88-90%, which remains suitable for many uses but with a minor trade-off in optical precision.

Weight and Thickness Differences

Polycarbonate sheets are generally lighter than acrylic sheets while maintaining superior impact resistance, weighing approximately 1.2 grams per cubic centimeter compared to acrylic's 1.18 grams per cubic centimeter density. Polycarbonate sheets can be produced in thinner gauges without compromising strength, typically ranging from 0.75 mm to 12 mm, whereas acrylic sheets often require thicker dimensions for similar structural integrity, ranging from 1 mm to 25 mm. The combination of lower weight and thinner profile makes polycarbonate ideal for applications requiring lightweight, durable materials such as glazing, protective barriers, and outdoor signage.

Weather Resistance and Durability

Polycarbonate sheets exhibit superior weather resistance and durability compared to acrylic sheets, maintaining clarity and structural integrity even under extreme UV exposure and temperature fluctuations. Polycarbonate's impact resistance is significantly higher, making it less prone to cracking or breaking in harsh outdoor environments. Acrylic sheets, while offering good optical clarity and moderate UV resistance, tend to become brittle and discolor over time when exposed to prolonged weathering.

Thermal and UV Performance

Polycarbonate sheets exhibit superior thermal resistance with a heat deflection temperature around 135degC, compared to acrylic sheets which withstand up to approximately 80degC, making polycarbonate ideal for environments with high temperature fluctuations. In terms of UV performance, polycarbonate sheets often come with a built-in UV protective layer that effectively blocks harmful ultraviolet rays, whereas acrylic sheets generally have better natural UV resistance but can degrade under prolonged exposure without additional coatings. The combination of high impact resistance and enhanced UV protection positions polycarbonate sheets as a preferred choice for outdoor applications requiring durability and thermal stability.

Ease of Fabrication and Installation

Polycarbonate sheets offer superior ease of fabrication due to their flexibility and impact resistance, allowing effortless cutting, drilling, and thermoforming without cracking. Acrylic sheets, while providing a smooth finish, are more brittle and prone to chipping or cracking during machining, requiring careful handling and specialized tools. Installation of polycarbonate sheets is faster and more forgiving, as they can withstand bending and stress, whereas acrylic sheets need precise alignment and support to prevent damage.

Cost Analysis: Polycarbonate vs Acrylic

Polycarbonate sheets generally cost more than acrylic sheets due to their superior impact resistance and durability, making them a cost-effective choice for applications requiring long-term performance and safety. Acrylic sheets are more affordable upfront but may incur higher replacement or maintenance costs over time because they are more prone to cracking and UV damage. Your project budget should balance initial material expenses with expected lifespan and performance requirements to determine the best value between polycarbonate and acrylic.

Best Applications and Use Cases

Polycarbonate sheets excel in impact resistance and UV protection, making them ideal for security glazing, greenhouse panels, and skylights where durability and weather resistance are essential. Acrylic sheets offer superior optical clarity and scratch resistance, suitable for displays, signage, and light fixtures that require aesthetic appeal and precision. Choosing between polycarbonate and acrylic depends on specific application needs such as toughness versus clarity and exposure to environmental stressors.

Polycarbonate Sheet vs Acrylic Sheet Infographic

libmatt.com

libmatt.com