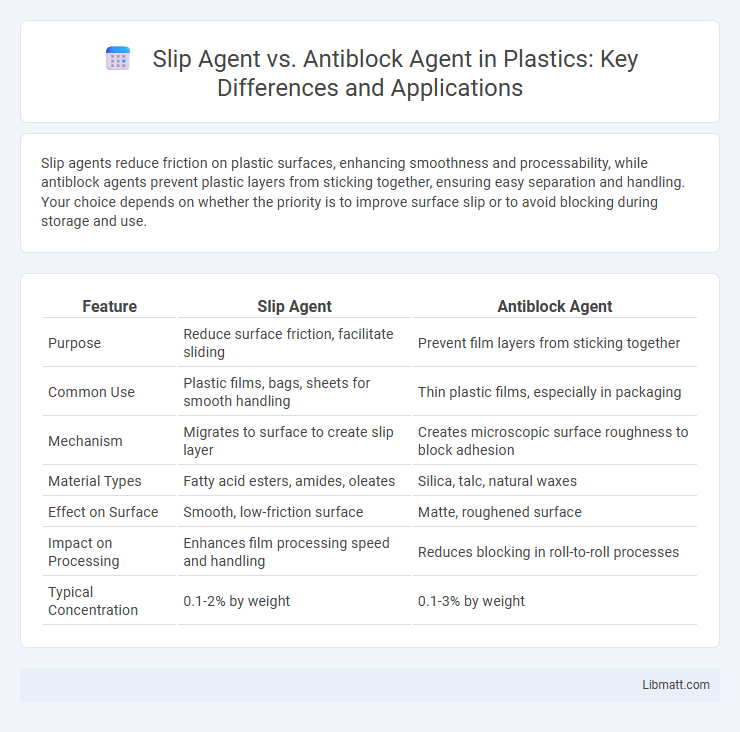

Slip agents reduce friction on plastic surfaces, enhancing smoothness and processability, while antiblock agents prevent plastic layers from sticking together, ensuring easy separation and handling. Your choice depends on whether the priority is to improve surface slip or to avoid blocking during storage and use.

Table of Comparison

| Feature | Slip Agent | Antiblock Agent |

|---|---|---|

| Purpose | Reduce surface friction, facilitate sliding | Prevent film layers from sticking together |

| Common Use | Plastic films, bags, sheets for smooth handling | Thin plastic films, especially in packaging |

| Mechanism | Migrates to surface to create slip layer | Creates microscopic surface roughness to block adhesion |

| Material Types | Fatty acid esters, amides, oleates | Silica, talc, natural waxes |

| Effect on Surface | Smooth, low-friction surface | Matte, roughened surface |

| Impact on Processing | Enhances film processing speed and handling | Reduces blocking in roll-to-roll processes |

| Typical Concentration | 0.1-2% by weight | 0.1-3% by weight |

Introduction to Slip Agents and Antiblock Agents

Slip agents and antiblock agents are essential additives in plastic film manufacturing, enhancing the surface properties of polymers. Slip agents reduce friction between plastic layers, improving handling and processing efficiency, while antiblock agents prevent films from sticking together by creating micro-roughness on the surface. Both agents play crucial roles in packaging applications, ensuring smooth operation and optimal product performance.

What are Slip Agents?

Slip agents are additives used in polymer films to reduce surface friction, enhancing the material's sliding properties and improving processability during manufacturing. They migrate to the film surface, forming a lubricating layer that minimizes sticking and blocking between film layers. Common slip agents include erucamide and oleamide, which are compatible with various plastics like polyethylene and polypropylene.

What are Antiblock Agents?

Antiblock agents are additives used in plastic films to prevent the layers from sticking together after processing, enhancing the film's unwind and handling properties. These agents reduce the coefficient of friction between surfaces by creating micro-sized particles on the film surface that act as spacers. Understanding the role of antiblock agents can help you choose the right formulation to improve your product's performance and processing efficiency.

Key Differences Between Slip Agents and Antiblock Agents

Slip agents reduce friction on polymer surfaces by migrating to the interface, enhancing material flow and surface smoothness, while antiblock agents prevent film layers from sticking by creating microscopic surface irregularities. Slip agents are primarily used to improve processing and handling efficiency in films, whereas antiblock agents focus on maintaining film clarity and ease of separation. The effectiveness of each additive depends on the polymer type and intended application, influencing properties such as coefficient of friction and surface texture.

How Slip Agents Work in Polymer Films

Slip agents migrate to the polymer film surface, reducing friction by forming a lubricating layer that facilitates film processing and handling. They create a low-energy interface that allows easier film movement without damaging or sticking, enhancing production efficiency and product performance. Your choice between slip agents and antiblock agents depends on whether you need reduced friction or improved film separation.

Functionality of Antiblock Agents in Plastics

Antiblock agents improve the functionality of plastics by preventing the surfaces of film layers from sticking together, enhancing processability and handling during manufacturing and end-use. These agents create microscopic roughness on the plastic surface, reducing friction and enabling easier separation of sheets or rolls. Your plastic products benefit from improved clarity, reduced defects, and better machinability when antiblock agents are used.

Benefits of Using Slip Agents

Slip agents reduce friction and enhance surface slip of polymer films, improving processing efficiency and product performance in packaging, automotive, and textile applications. They minimize abrasion and blockiness, enabling smoother unwinding and better printability while maintaining clarity and mechanical strength. By optimizing hardness and migration rates, slip agents extend material lifespan and reduce defects during manufacturing.

Advantages of Antiblock Agents

Antiblock agents enhance plastic films by preventing surface adhesion, ensuring smoother unwinding and better processing efficiency. These agents improve transparency and surface feel while reducing scratches and friction, which directly benefits your packaging or manufacturing quality. Unlike slip agents that primarily reduce friction, antiblock agents focus on maintaining material integrity and visual clarity throughout production and end-use.

Choosing the Right Additive: Slip Agent vs Antiblock Agent

Choosing the right additive for your packaging or film production depends on the desired surface properties and functionality. Slip agents reduce friction between layers, enhancing machinability and preventing sticking, while antiblock agents create microscopic surface roughness to prevent films from clinging together. Understanding the specific application needs ensures your product achieves optimal performance and handling characteristics.

Applications and Industries Using Slip and Antiblock Agents

Slip agents and antiblock agents are extensively used in the packaging, film manufacturing, and automotive industries to enhance material properties. Slip agents reduce friction in plastic films, improving processing speed and product handling in sectors like food packaging and agriculture film production. Antiblock agents prevent adhesion between plastic layers in packaging films, ensuring smooth separation and optimal functionality in applications such as pharmaceutical blister packs and flexible industrial packaging.

Slip Agent vs Antiblock Agent Infographic

libmatt.com

libmatt.com