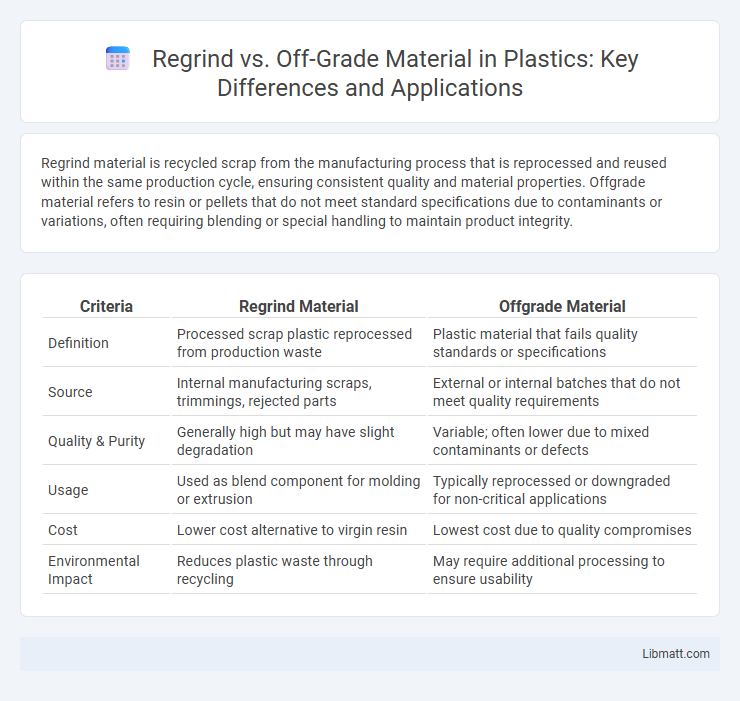

Regrind material is recycled scrap from the manufacturing process that is reprocessed and reused within the same production cycle, ensuring consistent quality and material properties. Offgrade material refers to resin or pellets that do not meet standard specifications due to contaminants or variations, often requiring blending or special handling to maintain product integrity.

Table of Comparison

| Criteria | Regrind Material | Offgrade Material |

|---|---|---|

| Definition | Processed scrap plastic reprocessed from production waste | Plastic material that fails quality standards or specifications |

| Source | Internal manufacturing scraps, trimmings, rejected parts | External or internal batches that do not meet quality requirements |

| Quality & Purity | Generally high but may have slight degradation | Variable; often lower due to mixed contaminants or defects |

| Usage | Used as blend component for molding or extrusion | Typically reprocessed or downgraded for non-critical applications |

| Cost | Lower cost alternative to virgin resin | Lowest cost due to quality compromises |

| Environmental Impact | Reduces plastic waste through recycling | May require additional processing to ensure usability |

Introduction to Regrind and Offgrade Materials

Regrind and offgrade materials are essential components in manufacturing processes involving plastics and polymers. Regrind refers to reclaimed scrap material that has been processed for reuse, maintaining consistent quality for further production. Offgrade materials, however, consist of products that do not meet specific quality standards, often requiring recycling or downgrading for alternative uses.

Definitions: What is Regrind Material?

Regrind material consists of previously processed plastic scrap that is ground into smaller particles for reuse in manufacturing, helping reduce waste and lower production costs. Offgrade material, in contrast, refers to batches of resin or plastic that do not meet quality specifications and are often reprocessed or recycled separately. Understanding the differences can help optimize Your material sourcing and recycling strategies for improved efficiency.

Understanding Offgrade Material

Offgrade material refers to production output that does not meet the required quality standards or specifications, often due to defects or inconsistencies during manufacturing. Unlike regrind, which involves recycling scrap or used materials back into the production process, offgrade material typically cannot be reused directly and may require reprocessing or disposal. Understanding offgrade material helps optimize resource management and minimize waste in your manufacturing operations.

Key Differences Between Regrind and Offgrade

Regrind material consists of scrap or waste plastic that has been ground down and is reused within the same production process, ensuring consistent quality and properties. Offgrade material refers to plastic resin that does not meet the original production specifications and is often sold at a lower price or recycled for less critical applications. Understanding these key differences helps you optimize material selection for cost-efficiency and product quality control.

Applications of Regrind in Manufacturing

Regrind material is extensively used in injection molding and extrusion processes to reduce production waste and lower raw material costs. Common applications include manufacturing automotive components, packaging films, and consumer goods where consistency in melt flow index and color quality is crucial. Utilizing regrind enhances sustainability practices by minimizing environmental impact and supporting circular manufacturing models.

Common Uses for Offgrade Material

Offgrade material is commonly used in manufacturing industries for applications such as filler in injection molding, blending with virgin resin to reduce costs, and prototype or non-critical parts production where surface finish and mechanical properties are less stringent. Your production processes can benefit from offgrade materials by optimizing cost efficiency without compromising essential functional requirements. Recycling offgrade materials also supports sustainability goals by minimizing waste sent to landfills.

Quality and Performance Comparison

Regrind material, derived from recycled production scrap, generally offers more consistent quality and performance due to controlled processing and particle size uniformity. Offgrade material, often sourced from lower-quality or contaminated batches, tends to exhibit variable properties, which can negatively impact final product durability and aesthetic standards. Using regrind in manufacturing maintains better mechanical integrity and reduces defects compared to offgrade material, making it preferable for high-performance applications.

Cost Implications: Regrind vs Offgrade

Regrind material typically reduces production costs by recycling scrap and defective parts back into the manufacturing process, minimizing raw material expenses. Offgrade material, often characterized by lower quality or specifications, may lead to cost savings upfront but can increase expenses due to higher rejection rates or additional processing required to meet standards. Evaluating the balance between cost savings from regrind reuse and potential quality issues from offgrade materials is critical for optimizing overall manufacturing efficiency.

Environmental Impact and Sustainability

Regrind material, derived from recycled plastic scrap within the manufacturing process, reduces landfill waste and lowers energy consumption by minimizing the need for virgin resin production. Offgrade material, often consisting of defective or out-of-spec products, can be reprocessed but may require more energy and additional sorting, impacting sustainability efforts. Your choice between regrind and offgrade materials significantly influences the environmental footprint and aligns with circular economy goals by promoting resource efficiency and waste reduction.

Choosing the Right Material: Factors to Consider

Choosing the right material between regrind and offgrade depends on factors such as product quality requirements, cost constraints, and manufacturing processes. Regrind material, derived from processed scrap, offers cost savings but may impact physical properties and appearance, while offgrade material, sourced from lower-grade virgin resin, provides more consistent performance. Your decision should balance material performance standards with budget and production efficiency to optimize end-use results.

Regrind vs Offgrade Material Infographic

libmatt.com

libmatt.com