Flexural strength measures a material's ability to resist bending forces, while tensile strength quantifies its capacity to withstand pulling or stretching forces. Understanding the difference between these properties helps you select the right material for applications requiring either resistance to bending or tension.

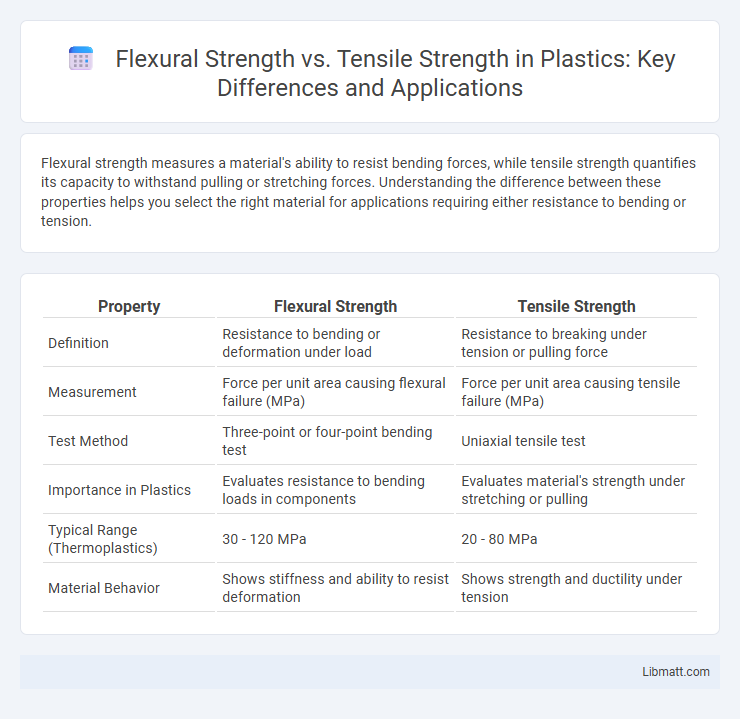

Table of Comparison

| Property | Flexural Strength | Tensile Strength |

|---|---|---|

| Definition | Resistance to bending or deformation under load | Resistance to breaking under tension or pulling force |

| Measurement | Force per unit area causing flexural failure (MPa) | Force per unit area causing tensile failure (MPa) |

| Test Method | Three-point or four-point bending test | Uniaxial tensile test |

| Importance in Plastics | Evaluates resistance to bending loads in components | Evaluates material's strength under stretching or pulling |

| Typical Range (Thermoplastics) | 30 - 120 MPa | 20 - 80 MPa |

| Material Behavior | Shows stiffness and ability to resist deformation | Shows strength and ductility under tension |

Introduction to Flexural and Tensile Strength

Flexural strength measures a material's ability to resist deformation under bending stress, while tensile strength indicates the maximum stress a material can withstand when stretched or pulled. These properties are crucial for evaluating the performance of materials in construction, manufacturing, and engineering applications. Understanding the differences between flexural and tensile strength helps you select the most suitable material for your project's specific load-bearing requirements.

Defining Flexural Strength

Flexural strength, also known as modulus of rupture, measures a material's ability to resist deformation under bending stress, indicating how much force it can withstand before fracturing. It is crucial in applications where materials experience bending loads, such as beams, slabs, and structural components. Unlike tensile strength, which tests resistance to pulling forces, flexural strength evaluates the combined effects of tension and compression on the surface of a material during bending.

Understanding Tensile Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking, crucial for assessing durability under tension. It is typically higher in materials like steel, indicating superior resistance to deformation under load compared to weaker materials. Understanding tensile strength helps you select the right materials for applications where resisting stretching forces is vital for safety and performance.

Key Differences Between Flexural and Tensile Strength

Flexural strength measures a material's ability to resist deformation under bending forces, while tensile strength evaluates resistance to breaking under tension. Flexural strength involves compressive and tensile stresses distributed across the material's cross-section, whereas tensile strength focuses solely on tensile stress applied uniformly. These differences impact material selection in structural applications, where bending loads dominate or direct pulling forces are critical.

Testing Methods for Flexural Strength

Flexural strength testing involves subjecting a material specimen to bending until failure, commonly using three-point or four-point bending tests to measure its resistance to deformation under load. The three-point bending test applies force at a single midpoint while the specimen is supported at two ends, providing data on flexural modulus and stress. Compared to tensile strength testing, which pulls the material until it fractures, flexural testing better simulates real-world bending stress conditions in structural applications.

Testing Methods for Tensile Strength

Tensile strength is primarily evaluated using a universal testing machine that applies uniaxial force to a specimen until failure, measuring the maximum stress the material withstands. Common testing methods include the direct tension test, where cylindrical or dog-bone-shaped samples are pulled, and standardized tests like ASTM E8 for metals and ISO 527 for plastics. Accurate tensile strength testing requires precise sample preparation, controlled loading rates, and environmental conditions to ensure reliable and repeatable results.

Factors Influencing Flexural Strength

Flexural strength is influenced by factors such as material composition, geometry, and the presence of surface flaws, which affect how a material withstands bending forces. Temperature and loading rate also play crucial roles, altering the material's resistance to deformation and failure under flexural stress. Understanding these variables helps improve your design's durability by optimizing the balance between flexural and tensile strength in structural applications.

Factors Affecting Tensile Strength

Tensile strength is influenced by factors such as material composition, grain structure, and the presence of defects or impurities, which affect its ability to withstand stretching forces. Heat treatment and alloying elements can significantly enhance tensile strength by refining microstructure and improving bonding between atoms. Environmental conditions like temperature and corrosion also play a critical role in reducing tensile strength over time.

Practical Applications of Flexural vs Tensile Strength

Flexural strength is critical in applications where materials must resist bending forces, such as in beams, floor slabs, and bridges, ensuring they withstand load without deformation. Tensile strength is essential in components subjected to pulling or stretching forces, including cables, ropes, and structural reinforcements, where resistance to breaking under tension is paramount. Understanding the differences enables engineers to select appropriate materials and designs for targeted mechanical performance in construction, manufacturing, and product development.

Choosing the Right Strength Metric for Materials

Flexural strength measures a material's ability to resist deformation under bending stress, making it crucial for applications involving beams and slabs, while tensile strength gauges resistance to breaking under tension, essential for cables and structural components. Selecting the proper strength metric depends on the loading conditions and expected stresses in the application, ensuring accurate assessment of material performance. Engineers prioritize flexural strength for bending-dominated scenarios and tensile strength for tension-dominated uses to optimize material safety and durability.

Flexural Strength vs Tensile Strength Infographic

libmatt.com

libmatt.com