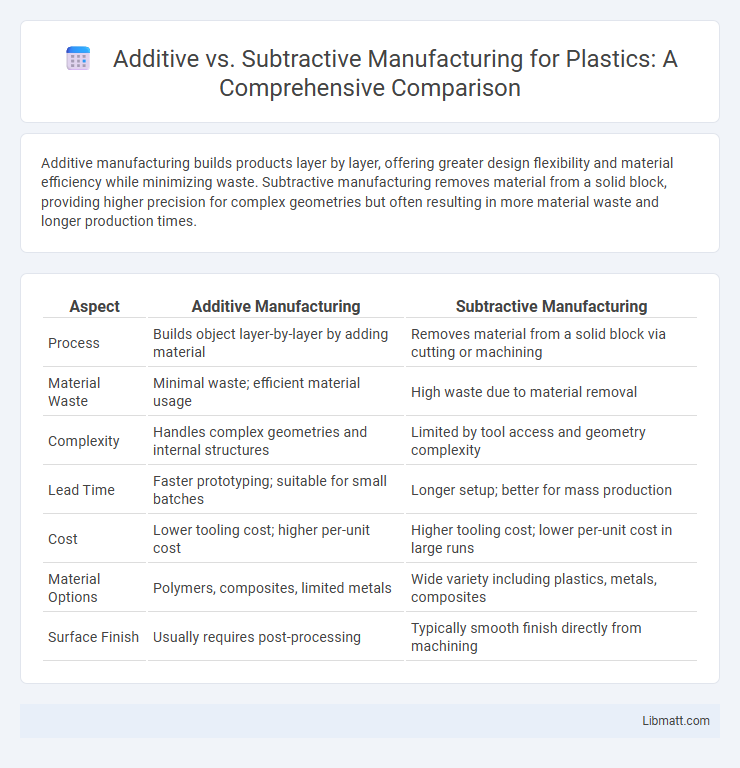

Additive manufacturing builds products layer by layer, offering greater design flexibility and material efficiency while minimizing waste. Subtractive manufacturing removes material from a solid block, providing higher precision for complex geometries but often resulting in more material waste and longer production times.

Table of Comparison

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Process | Builds object layer-by-layer by adding material | Removes material from a solid block via cutting or machining |

| Material Waste | Minimal waste; efficient material usage | High waste due to material removal |

| Complexity | Handles complex geometries and internal structures | Limited by tool access and geometry complexity |

| Lead Time | Faster prototyping; suitable for small batches | Longer setup; better for mass production |

| Cost | Lower tooling cost; higher per-unit cost | Higher tooling cost; lower per-unit cost in large runs |

| Material Options | Polymers, composites, limited metals | Wide variety including plastics, metals, composites |

| Surface Finish | Usually requires post-processing | Typically smooth finish directly from machining |

Introduction to Additive and Subtractive Manufacturing

Additive manufacturing builds objects layer by layer from digital models, enabling complex geometries and material efficiency. Subtractive manufacturing removes material from a solid block using cutting tools, providing high precision and surface finish. Both techniques serve distinct purposes across industries such as aerospace, automotive, and medical device production.

Key Principles of Additive Manufacturing

Additive Manufacturing builds objects layer by layer from digital models, enhancing design flexibility and minimizing material waste compared to Subtractive Manufacturing, which removes material from a solid block. This process enables complex geometries and customized prototypes with high precision using materials such as plastics, metals, and composites. Your innovation benefits from increased efficiency and reduced production costs through Additive Manufacturing's key principles of layering, digital integration, and minimal material usage.

Fundamental Concepts in Subtractive Manufacturing

Subtractive manufacturing involves the process of removing material from a solid block using tools like CNC machines, lathes, or milling machines to achieve the desired shape. It relies on precision cutting, drilling, or grinding to eliminate excess material, emphasizing accuracy and surface finish quality. The fundamental concept centers around material removal, which contrasts with additive manufacturing's layer-by-layer material addition, impacting production speed, waste generation, and design complexity.

Material Types and Compatibility

Additive manufacturing supports a wide range of material types, including plastics, metals, ceramics, and composites, offering high compatibility with complex geometries and customized applications. Subtractive manufacturing primarily works with metals, plastics, and wood, requiring materials that are machinable and typically limiting geometric complexity due to tool accessibility. Your choice between these methods should consider the material properties, desired precision, and production volume to match the process with compatible material types effectively.

Process Efficiency and Production Speed

Additive Manufacturing builds products layer by layer, significantly reducing material waste and enabling complex geometries, which enhances process efficiency compared to Subtractive Manufacturing that removes material from a solid block. Production speed in Additive Manufacturing is often faster for small batches and prototypes due to minimal setup times, whereas Subtractive Manufacturing excels in high-volume production with faster cycle times per part. Optimizing manufacturing workflows involves balancing the rapid prototyping benefits of additive techniques with the high-throughput capabilities of subtractive methods.

Cost Analysis: Additive vs Subtractive

Additive manufacturing typically reduces material waste and lowers tooling costs, making it more cost-effective for low-volume and complex designs. Subtractive manufacturing generally incurs higher expenses due to material removal and tool wear, but it offers faster production rates for large-scale runs. Cost analysis reveals additive processes excel in prototyping and customized parts, while subtractive methods remain economical for mass production with standardized geometries.

Design Flexibility and Complexity

Additive manufacturing enables unparalleled design flexibility by allowing the creation of complex geometries, internal cavities, and intricate structures that are impossible or cost-prohibitive with subtractive methods. Subtractive manufacturing is limited by cutting tool accessibility and material removal constraints, often restricting design complexity and increasing waste. Your choice of manufacturing technique significantly influences the ability to produce highly detailed and customized parts efficiently.

Surface Finish and Accuracy Comparison

Additive manufacturing typically produces parts with a rougher surface finish due to layer-by-layer deposition, often requiring post-processing for smoother textures. Subtractive manufacturing excels in achieving high accuracy and fine surface finishes as it involves material removal using precise cutting tools, resulting in tighter tolerances and superior detail. Industries demanding flawless surface quality and exact dimensions, such as aerospace or medical devices, often prefer subtractive methods for final parts.

Environmental Impact and Sustainability

Additive manufacturing significantly reduces waste by building objects layer by layer, using only the necessary material, which minimizes environmental impact compared to subtractive manufacturing that removes excess material and generates more scrap. Energy consumption in additive processes can be lower, especially for complex or customized parts, improving overall sustainability. Your choice of manufacturing method can influence carbon footprint and resource efficiency, making additive manufacturing a more eco-friendly option for sustainable production.

Applications and Industry Use Cases

Additive manufacturing excels in producing complex geometries and customized products, making it ideal for aerospace components, medical implants, and automotive prototypes where precision and material efficiency are crucial. Subtractive manufacturing remains dominant in industries like automotive, aerospace, and consumer electronics due to its ability to produce high-strength metal parts with tight tolerances from solid blocks or sheets. Your choice between these methods should consider the specific application requirements, material properties, and production volume to optimize manufacturing efficiency and cost.

Additive Manufacturing vs Subtractive Manufacturing Infographic

libmatt.com

libmatt.com