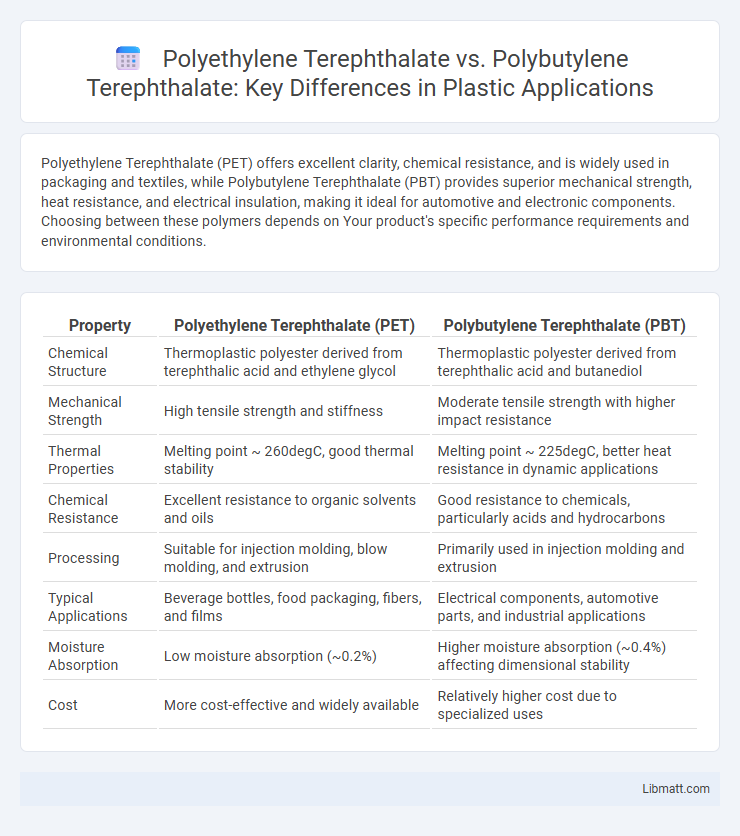

Polyethylene Terephthalate (PET) offers excellent clarity, chemical resistance, and is widely used in packaging and textiles, while Polybutylene Terephthalate (PBT) provides superior mechanical strength, heat resistance, and electrical insulation, making it ideal for automotive and electronic components. Choosing between these polymers depends on Your product's specific performance requirements and environmental conditions.

Table of Comparison

| Property | Polyethylene Terephthalate (PET) | Polybutylene Terephthalate (PBT) |

|---|---|---|

| Chemical Structure | Thermoplastic polyester derived from terephthalic acid and ethylene glycol | Thermoplastic polyester derived from terephthalic acid and butanediol |

| Mechanical Strength | High tensile strength and stiffness | Moderate tensile strength with higher impact resistance |

| Thermal Properties | Melting point ~ 260degC, good thermal stability | Melting point ~ 225degC, better heat resistance in dynamic applications |

| Chemical Resistance | Excellent resistance to organic solvents and oils | Good resistance to chemicals, particularly acids and hydrocarbons |

| Processing | Suitable for injection molding, blow molding, and extrusion | Primarily used in injection molding and extrusion |

| Typical Applications | Beverage bottles, food packaging, fibers, and films | Electrical components, automotive parts, and industrial applications |

| Moisture Absorption | Low moisture absorption (~0.2%) | Higher moisture absorption (~0.4%) affecting dimensional stability |

| Cost | More cost-effective and widely available | Relatively higher cost due to specialized uses |

Introduction to Polyethylene Terephthalate (PET) and Polybutylene Terephthalate (PBT)

Polyethylene Terephthalate (PET) is a widely used thermoplastic polymer known for its excellent clarity, mechanical strength, and chemical resistance, making it ideal for packaging and textile applications. Polybutylene Terephthalate (PBT) is a type of polyester with superior impact resistance, electrical insulation properties, and dimensional stability, commonly used in automotive and electrical components. Understanding the distinctions between PET and PBT helps you select the most suitable material based on performance requirements and environmental conditions.

Chemical Structure Comparison: PET vs PBT

Polyethylene Terephthalate (PET) and Polybutylene Terephthalate (PBT) differ primarily in their chemical backbone, where PET contains ethylene glycol units and PBT incorporates butylene glycol units, affecting their molecular flexibility and thermal properties. PET's structure provides higher stiffness and chemical resistance, making it ideal for packaging and textiles, while PBT's longer butylene segments grant greater impact resistance and better electrical insulation, suitable for automotive and electrical components. Understanding these chemical structure variations can help you select the appropriate polymer for specific engineering or manufacturing applications.

Mechanical and Physical Properties

Polyethylene Terephthalate (PET) exhibits high tensile strength, excellent chemical resistance, and moderate thermal stability, making it ideal for packaging and fibers. Polybutylene Terephthalate (PBT) offers superior electrical insulating properties, higher impact resistance, and better dimensional stability at elevated temperatures. When choosing between PET and PBT for your application, consider PBT for components requiring enhanced toughness and heat resistance, while PET suits lightweight, rigid structures.

Thermal Resistance and Stability

Polyethylene Terephthalate (PET) exhibits moderate thermal resistance with a melting point around 260degC, making it suitable for applications requiring dimensional stability under heat. Polybutylene Terephthalate (PBT) offers enhanced thermal stability and a slightly lower melting point near 225degC but maintains superior resistance to thermal degradation and stress cracking. Your choice between PET and PBT depends on the specific thermal demands and stability requirements of the end-use environment.

Processing Methods: Injection Molding and Extrusion

Polyethylene Terephthalate (PET) and Polybutylene Terephthalate (PBT) both excel in injection molding and extrusion processes, exhibiting distinct thermal and mechanical properties impacting their processing parameters. PET demonstrates higher melting temperatures around 250degC and is commonly used in fiber production through extrusion, whereas PBT melts at lower temperatures near 225degC, offering faster crystallization rates favorable for injection molding complex parts. Optimized mold temperature control and precise drying conditions are critical for both polymers to prevent hydrolysis and ensure dimensional stability during manufacturing.

Applications of PET in Industry

Polyethylene Terephthalate (PET) is widely used in packaging, particularly for beverage bottles and food containers, due to its excellent strength, lightweight nature, and recyclability. The textile industry relies on PET fibers for producing durable fabrics and clothing materials. Your industrial applications also include electrical insulation, automotive components, and film production, making PET a versatile choice across multiple sectors.

Applications of PBT in Industry

Polybutylene Terephthalate (PBT) is extensively used in automotive components, electrical housings, and consumer electronics due to its excellent chemical resistance, dimensional stability, and electrical insulation properties. Unlike Polyethylene Terephthalate (PET), PBT offers superior resistance to heat and impact, making it ideal for precision parts such as connectors, switches, and housings in industrial manufacturing. Your choice of PBT can enhance product durability and performance in demanding environments where mechanical strength and thermal resistance are critical.

Environmental Impact and Recyclability

Polyethylene Terephthalate (PET) is widely recognized for its superior recyclability, with well-established collection and recycling systems resulting in lower environmental impact due to reduced landfill waste and energy-efficient reuse. Polybutylene Terephthalate (PBT), while offering excellent thermal and chemical resistance, is less commonly recycled, leading to a higher environmental footprint from limited recycling infrastructure and potential accumulation in waste streams. You can contribute to sustainability efforts by choosing PET-based products, which support circular economy initiatives through more effective recycling and reduced plastic pollution.

Cost Analysis and Market Trends

Polyethylene Terephthalate (PET) typically offers a lower cost per kilogram compared to Polybutylene Terephthalate (PBT), making PET a favored choice for high-volume applications in packaging and textiles. Market trends show increasing demand for PET due to its recyclability and wide adoption in the beverage industry, while PBT's higher performance properties drive growth in automotive and electrical sectors despite its higher price point. Your selection between PET and PBT should weigh cost efficiency against specific application requirements and evolving market dynamics favoring sustainability and advanced materials.

Choosing Between PET and PBT: Key Considerations

Polyethylene Terephthalate (PET) offers high tensile strength, excellent chemical resistance, and superior clarity, making it ideal for packaging and transparent applications. Polybutylene Terephthalate (PBT) provides enhanced dimensional stability, better electrical insulation, and superior resistance to heat and wear, suitable for automotive and electronic components. Choosing between PET and PBT depends on application-specific requirements such as mechanical strength, thermal resistance, and environmental exposure.

Polyethylene Terephthalate vs Polybutylene Terephthalate Infographic

libmatt.com

libmatt.com