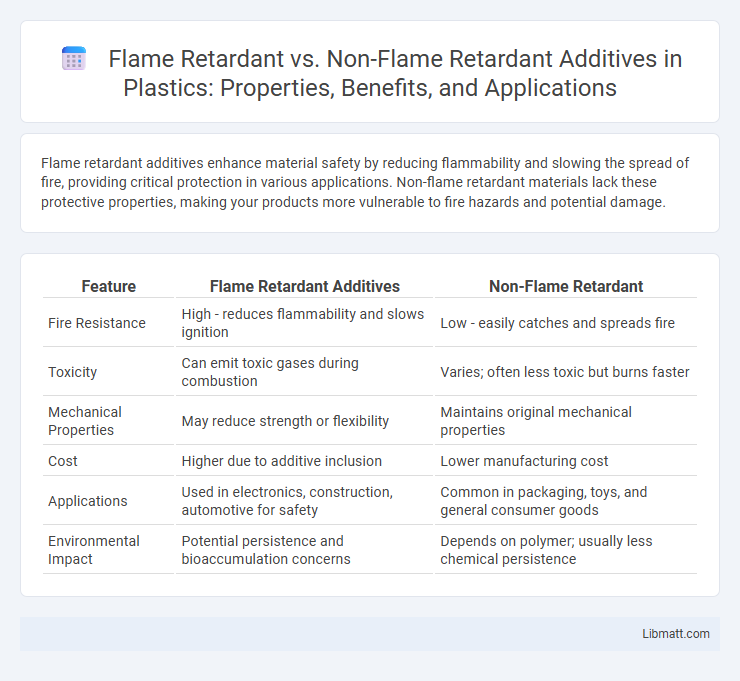

Flame retardant additives enhance material safety by reducing flammability and slowing the spread of fire, providing critical protection in various applications. Non-flame retardant materials lack these protective properties, making your products more vulnerable to fire hazards and potential damage.

Table of Comparison

| Feature | Flame Retardant Additives | Non-Flame Retardant |

|---|---|---|

| Fire Resistance | High - reduces flammability and slows ignition | Low - easily catches and spreads fire |

| Toxicity | Can emit toxic gases during combustion | Varies; often less toxic but burns faster |

| Mechanical Properties | May reduce strength or flexibility | Maintains original mechanical properties |

| Cost | Higher due to additive inclusion | Lower manufacturing cost |

| Applications | Used in electronics, construction, automotive for safety | Common in packaging, toys, and general consumer goods |

| Environmental Impact | Potential persistence and bioaccumulation concerns | Depends on polymer; usually less chemical persistence |

Introduction to Flame Retardant Additives

Flame retardant additives are specialized chemicals integrated into materials to inhibit or resist the spread of fire, enhancing safety in various applications. These additives alter the combustion process by promoting char formation, diluting flammable gases, or interfering with radical reactions, which non-flame retardant materials lack. Understanding the role of flame retardant additives helps you select safer, compliant products for construction, electronics, and textiles.

Understanding Non-Flame Retardant Materials

Non-flame retardant materials lack chemical additives designed to resist ignition and slow combustion, making them more susceptible to fire hazards in various applications. These materials often exhibit higher flammability, increased risk of heat damage, and may not meet stringent safety regulations required in construction, electronics, or textiles. Understanding the limitations and fire risks associated with non-flame retardant substances helps you choose safer alternatives when fire resistance is a critical concern.

Chemical Composition: Flame Retardant vs Non-Flame Retardant

Flame retardant additives typically contain halogenated compounds, phosphorus-based chemicals, or metal hydroxides that disrupt combustion processes by promoting char formation or releasing flame-inhibiting gases. In contrast, non-flame retardant materials lack these specific chemical agents, resulting in higher flammability and faster ignition times. The chemical composition of flame retardants fundamentally alters the thermal degradation pathway, enhancing fire resistance compared to standard polymers or resins without such additives.

Key Applications in Industry

Flame retardant additives are essential in industries such as electronics, construction, automotive, and textiles, where fire safety standards mandate enhanced material performance to prevent ignition and slow flame propagation. Non-flame retardant materials are typically utilized in applications where fire risk is minimal, such as packaging and certain consumer goods, prioritizing cost-effectiveness and environmental considerations. The choice between flame retardant and non-flame retardant additives significantly impacts regulatory compliance, product durability, and safety certifications across diverse industrial sectors.

Fire Safety Standards and Regulations

Flame retardant additives play a crucial role in meeting stringent fire safety standards and regulations such as UL 94, NFPA 701, and EN 13501-1 by significantly reducing flammability and smoke generation of materials. Non-flame retardant materials often fail to comply with these requirements, posing higher risks of rapid fire propagation, increased heat release, and toxic smoke emission. Regulatory agencies mandate the use of flame retardant additives in industries like construction, electronics, and textiles to ensure product certification, consumer safety, and legal compliance.

Performance and Efficacy Comparison

Flame retardant additives significantly enhance material performance by reducing flammability and slowing combustion rates, thereby improving safety in various applications such as electronics, construction, and textiles. Non-flame retardant materials lack these protective properties, leading to higher ignition risk and quicker flame propagation. The efficacy of flame retardant additives is measured through standardized tests like UL-94 and LOI (Limiting Oxygen Index), demonstrating superior resistance and increased time to ignition compared to non-flame retardant counterparts.

Environmental and Health Impacts

Flame retardant additives often contain chemicals like brominated flame retardants that persist in the environment and bioaccumulate, posing risks to aquatic ecosystems and wildlife. Non-flame retardant materials reduce exposure to potentially toxic substances, minimizing human health concerns such as endocrine disruption and respiratory issues. Choosing flame retardant additives with safer chemistries significantly decreases long-term environmental contamination and health hazards.

Cost Implications and Economic Considerations

Flame retardant additives increase the initial production cost of materials due to specialized chemicals and processing requirements, impacting your budget for large-scale manufacturing. Non-flame retardant materials generally offer lower upfront costs but may lead to higher long-term expenses from fire damage, liability risks, and insurance premiums. Evaluating cost implications requires balancing immediate financial outlay against potential economic losses from fire hazards and regulatory compliance.

Sustainability and Future Innovations

Flame retardant additives are evolving to prioritize sustainability by incorporating bio-based and non-toxic materials that reduce environmental impact while maintaining fire safety standards. Innovations in non-flame retardant alternatives focus on enhancing inherent material properties, such as thermal resistance and self-extinguishing capabilities, to lessen chemical reliance. Your choice between these technologies influences the eco-friendliness and future adaptability of materials used in construction, electronics, and textiles.

Choosing the Right Additive for Your Application

Flame retardant additives enhance the fire resistance of materials, making them essential for applications requiring improved safety and compliance with fire regulations in industries such as construction and electronics. Non-flame retardant additives focus on other performance improvements like durability, flexibility, or UV resistance but do not provide fire protection, making them suitable for applications where fire risk is minimal. Selecting the right additive depends on the specific requirements of the end-use, including regulatory standards, environmental impact, and material compatibility to ensure optimal performance and safety.

Flame Retardant Additives vs Non-Flame Retardant Infographic

libmatt.com

libmatt.com