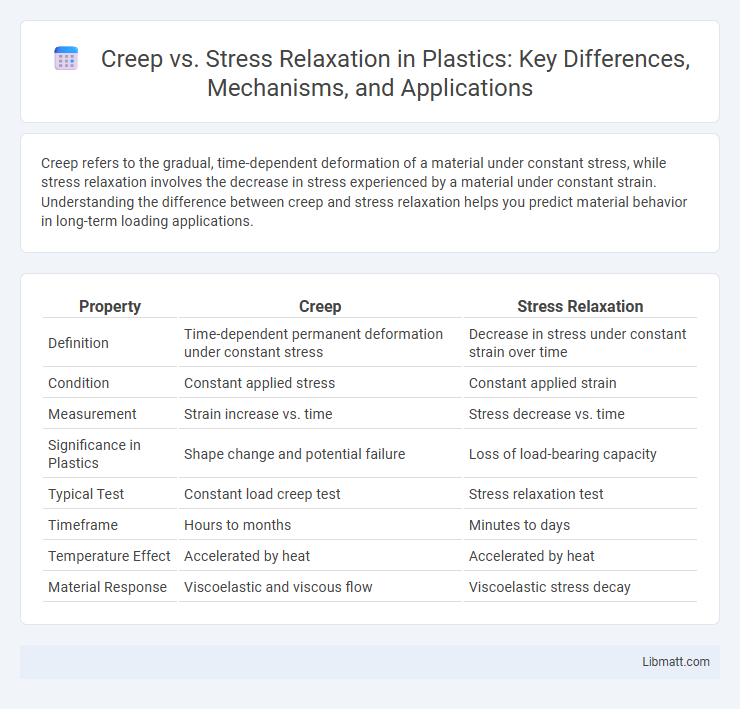

Creep refers to the gradual, time-dependent deformation of a material under constant stress, while stress relaxation involves the decrease in stress experienced by a material under constant strain. Understanding the difference between creep and stress relaxation helps you predict material behavior in long-term loading applications.

Table of Comparison

| Property | Creep | Stress Relaxation |

|---|---|---|

| Definition | Time-dependent permanent deformation under constant stress | Decrease in stress under constant strain over time |

| Condition | Constant applied stress | Constant applied strain |

| Measurement | Strain increase vs. time | Stress decrease vs. time |

| Significance in Plastics | Shape change and potential failure | Loss of load-bearing capacity |

| Typical Test | Constant load creep test | Stress relaxation test |

| Timeframe | Hours to months | Minutes to days |

| Temperature Effect | Accelerated by heat | Accelerated by heat |

| Material Response | Viscoelastic and viscous flow | Viscoelastic stress decay |

Introduction to Creep and Stress Relaxation

Creep refers to the slow, time-dependent deformation of a material under constant stress, typically occurring at high temperature or prolonged loading conditions. Stress relaxation describes the gradual decrease in stress experienced by a material when subjected to a constant strain over time, often relevant in polymers and viscoelastic materials. Both phenomena are critical in materials science for predicting long-term behavior and ensuring structural integrity in engineering applications.

Core Definitions: What is Creep?

Creep is the time-dependent, permanent deformation of a material subjected to a constant stress, typically occurring at elevated temperatures or over prolonged periods. It contrasts with stress relaxation, which involves the gradual reduction of stress under a constant strain. Understanding creep behavior is crucial for materials used in high-temperature environments such as turbine blades, pipelines, and aerospace components.

Core Definitions: What is Stress Relaxation?

Stress relaxation is the gradual decrease in stress experienced by a material when subjected to a constant strain over time. Unlike creep, which measures deformation under constant stress, stress relaxation focuses on how internal stress diminishes while the material's strain remains fixed. Understanding stress relaxation helps predict material behavior in applications where maintaining constant deformation is critical for Your designs.

Fundamental Mechanisms Behind Creep

Creep occurs due to time-dependent plastic deformation under constant stress, where atomic diffusion and dislocation movement facilitate gradual elongation. Stress relaxation involves the reduction of stress under constant strain as internal stresses redistribute through viscoelastic or viscoplastic mechanisms. Fundamental creep mechanisms include diffusional flow, dislocation glide, and climb, which dominate at different temperature and stress regimes, influencing material durability in high-temperature applications.

Fundamental Mechanisms Behind Stress Relaxation

Stress relaxation occurs as materials experience a gradual decrease in stress under a constant strain, driven by molecular rearrangements such as polymer chain realignment or atomic diffusion in metals. Your understanding of this phenomenon involves recognizing that stress relaxation results from internal structural adjustments that dissipate stored elastic energy over time. These fundamental mechanisms differentiate stress relaxation from creep, which primarily involves time-dependent strain under constant stress.

Key Differences Between Creep and Stress Relaxation

Creep and stress relaxation are distinct mechanical behaviors observed in materials under different conditions: creep occurs when a constant load is applied, causing the material to deform progressively over time, whereas stress relaxation happens when a material is held at a fixed deformation and the internal stress gradually decreases. Key differences include the type of applied constraint--constant stress in creep versus constant strain in stress relaxation--and their respective time-dependent responses, with creep emphasizing strain increase and stress relaxation highlighting stress reduction. Understanding these differences is crucial for predicting material performance and durability in engineering applications, ensuring Your designs accommodate long-term deformation or stress changes effectively.

Factors Influencing Creep and Stress Relaxation

Temperature, applied stress, and material composition significantly influence creep and stress relaxation behaviors in polymers and metals. Higher temperatures accelerate molecular movement, increasing creep rates, while stress relaxation depends on the material's viscoelastic properties and how it redistributes internal stresses over time. Your understanding of these factors helps predict long-term material performance under constant load or deformation conditions.

Material Examples: Metals, Polymers, and Ceramics

Creep and stress relaxation behavior varies significantly across metals, polymers, and ceramics due to their distinct microstructures and bonding characteristics. Metals such as aluminum and steel exhibit creep at high temperatures through dislocation movement, while polymers like polyethylene experience both creep and stress relaxation due to viscoelastic properties. Ceramics typically show minimal creep but can undergo stress relaxation through microcracking or diffusion mechanisms under prolonged stress.

Real-World Applications and Implications

Creep and stress relaxation significantly impact the longevity and reliability of materials in industries such as aerospace, civil engineering, and electronics. Creep can lead to gradual deformation under constant load, affecting structural integrity in bridges and turbine blades, while stress relaxation reduces stress in materials under constant strain, influencing gasket and seal performance. Understanding these phenomena helps you design components that withstand long-term operational stresses, ensuring safety and durability.

Summary: Choosing the Appropriate Analysis

Creep measures material deformation over time under constant stress, while stress relaxation tracks the decline in stress under constant strain. Selecting the appropriate analysis depends on whether your application involves sustained loads causing gradual deformation or fixed deformations requiring stress reduction assessment. Understanding these differences ensures accurate prediction of long-term material performance and reliability.

Creep vs stress relaxation Infographic

libmatt.com

libmatt.com