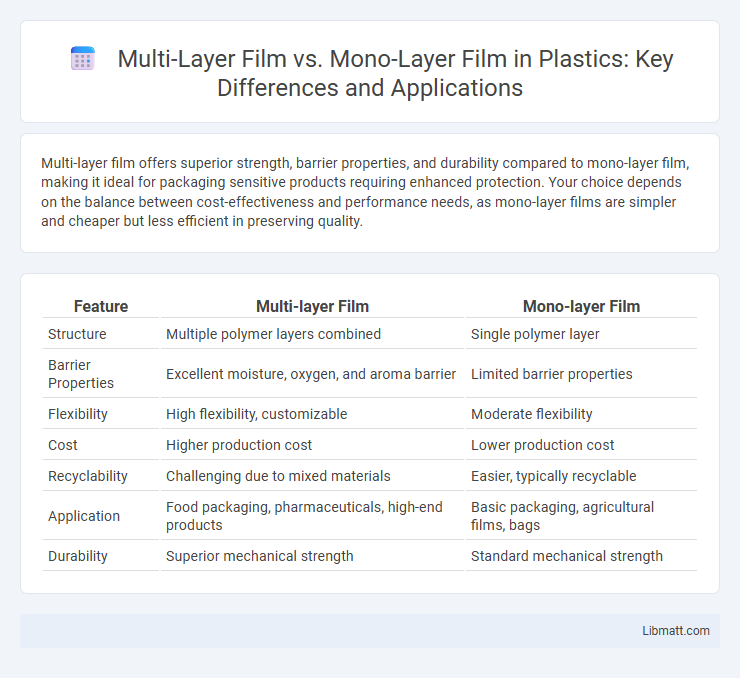

Multi-layer film offers superior strength, barrier properties, and durability compared to mono-layer film, making it ideal for packaging sensitive products requiring enhanced protection. Your choice depends on the balance between cost-effectiveness and performance needs, as mono-layer films are simpler and cheaper but less efficient in preserving quality.

Table of Comparison

| Feature | Multi-layer Film | Mono-layer Film |

|---|---|---|

| Structure | Multiple polymer layers combined | Single polymer layer |

| Barrier Properties | Excellent moisture, oxygen, and aroma barrier | Limited barrier properties |

| Flexibility | High flexibility, customizable | Moderate flexibility |

| Cost | Higher production cost | Lower production cost |

| Recyclability | Challenging due to mixed materials | Easier, typically recyclable |

| Application | Food packaging, pharmaceuticals, high-end products | Basic packaging, agricultural films, bags |

| Durability | Superior mechanical strength | Standard mechanical strength |

Introduction to Packaging Films

Multi-layer films consist of multiple bonded layers of different materials designed to provide enhanced barrier properties, strength, and flexibility, making them ideal for packaging sensitive products like food and pharmaceuticals. Mono-layer films are made from a single type of material, typically offering simplicity and cost-effectiveness but limited protection against moisture, oxygen, or chemical contamination. Your choice between multi-layer and mono-layer packaging films depends on the specific requirements of product preservation and shelf life.

Defining Multi-layer Films

Multi-layer films consist of multiple thin polymer layers, each providing specific properties such as barrier protection, strength, and flexibility, combined into a single film structure. These films enhance performance in packaging applications by improving moisture resistance, oxygen barrier, and mechanical durability compared to mono-layer films made from a single polymer layer. The engineered combination of materials in multi-layer films offers tailored protection for food, pharmaceuticals, and industrial products.

Understanding Mono-layer Films

Mono-layer films consist of a single polymer layer, providing uniform thickness and consistent mechanical properties ideal for simple packaging applications. Their manufacturing process is more cost-effective and faster compared to multi-layer films, making them suitable for products that do not require specialized barrier protection. You can rely on mono-layer films for basic moisture resistance and strength but may need multi-layer films for enhanced gas barrier or flexibility.

Key Material Differences

Multi-layer films consist of multiple polymer layers, such as polyethylene, polypropylene, and nylon, each providing distinct properties like improved barrier resistance, strength, and flexibility. Mono-layer films are made from a single polymer type, typically polyethylene or polypropylene, offering simplicity in manufacturing but limited functional performance compared to multi-layer structures. The combination of diverse materials in multi-layer films results in enhanced durability, moisture protection, and oxygen barrier capabilities essential for packaging applications.

Performance and Barrier Properties

Multi-layer films offer superior performance and enhanced barrier properties by combining different polymer materials that optimize protection against moisture, oxygen, and UV light, ensuring extended shelf life for your products. Mono-layer films, while simpler and more cost-effective, generally provide lower barrier resistance and mechanical strength, limiting their use in high-performance applications. Selecting multi-layer films improves durability and preserves product quality through advanced barrier technology tailored to specific packaging needs.

Cost Comparison and Economic Efficiency

Multi-layer films generally have higher initial costs due to complex manufacturing processes and multiple materials but offer superior barrier properties that extend product shelf life, leading to reduced waste and overall cost savings. Mono-layer films are cheaper upfront with simpler production but may increase packaging failures and product spoilage, raising long-term expenses. You can achieve better economic efficiency with multi-layer films by balancing higher material costs against improved durability and preservation benefits.

Environmental Impact and Sustainability

Multi-layer films typically present greater environmental challenges due to their complex composition, which hinders recycling and prolongs degradation time in landfills. Mono-layer films, often made from a single polymer type, offer improved recyclability and lower environmental footprints, contributing to more sustainable waste management practices. Choosing mono-layer films can significantly reduce plastic waste accumulation and enhance circular economy efforts in packaging industries.

Applications in Various Industries

Multi-layer films offer enhanced barrier properties, making them ideal for food packaging, pharmaceuticals, and electronics where moisture, oxygen, and light protection are critical. Mono-layer films are commonly used in applications such as agricultural films, carrier bags, and disposable packaging due to their simplicity and cost-effectiveness. Industries like automotive and construction also employ multi-layer films for improved durability and thermal insulation.

Challenges and Limitations

Multi-layer films present challenges in recycling due to the difficulty of separating different polymer layers, which limits sustainable disposal options and increases environmental impact. Mono-layer films, while easier to recycle, often lack the advanced barrier and mechanical properties required for high-performance packaging, making them less versatile. Both film types face limitations in balancing functional performance with eco-friendly end-of-life solutions, posing significant hurdles for industry adoption.

Future Trends in Packaging Film Technology

Multi-layer films offer enhanced barrier properties, flexibility, and durability compared to mono-layer films, making them ideal for advanced packaging needs. Future trends in packaging film technology emphasize sustainability, with innovations in biodegradable and recyclable multi-layer composites designed to reduce environmental impact. Your packaging solutions will benefit from these cutting-edge materials, ensuring longer shelf life and improved product protection while aligning with eco-friendly standards.

Multi-layer Film vs Mono-layer Film Infographic

libmatt.com

libmatt.com