Fused Deposition Modeling (FDM) uses thermoplastic filaments heated and extruded layer by layer, making it ideal for durable prototypes and functional parts with a lower cost. Stereolithography (SLA) leverages laser-curing liquid resin to achieve high-resolution details and smooth surface finishes, suitable for intricate designs and precise modeling needs.

Table of Comparison

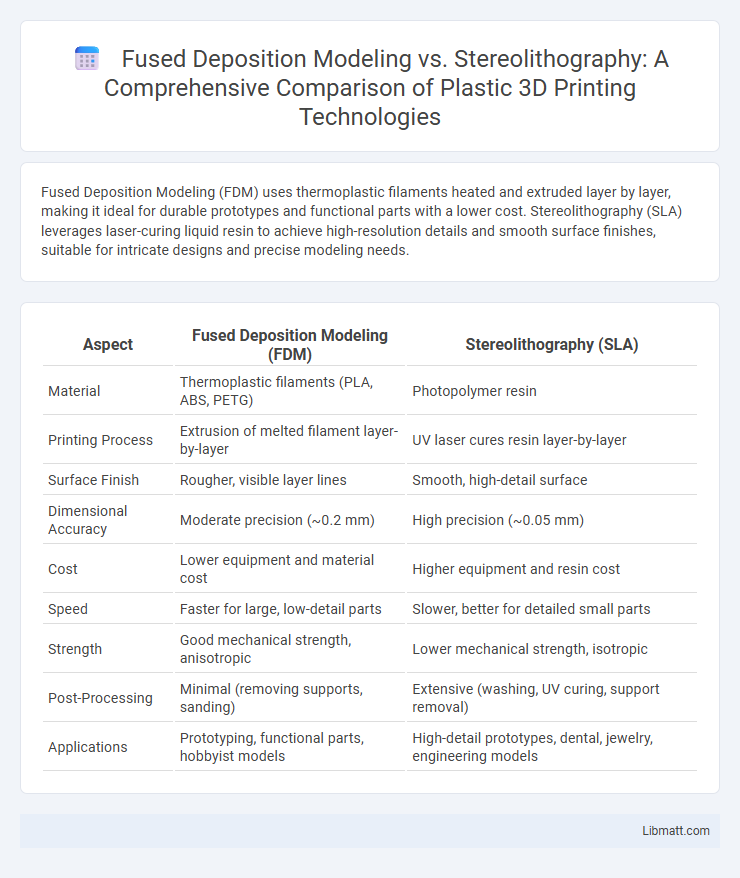

| Aspect | Fused Deposition Modeling (FDM) | Stereolithography (SLA) |

|---|---|---|

| Material | Thermoplastic filaments (PLA, ABS, PETG) | Photopolymer resin |

| Printing Process | Extrusion of melted filament layer-by-layer | UV laser cures resin layer-by-layer |

| Surface Finish | Rougher, visible layer lines | Smooth, high-detail surface |

| Dimensional Accuracy | Moderate precision (~0.2 mm) | High precision (~0.05 mm) |

| Cost | Lower equipment and material cost | Higher equipment and resin cost |

| Speed | Faster for large, low-detail parts | Slower, better for detailed small parts |

| Strength | Good mechanical strength, anisotropic | Lower mechanical strength, isotropic |

| Post-Processing | Minimal (removing supports, sanding) | Extensive (washing, UV curing, support removal) |

| Applications | Prototyping, functional parts, hobbyist models | High-detail prototypes, dental, jewelry, engineering models |

Introduction to Fused Deposition Modeling (FDM) and Stereolithography (SLA)

Fused Deposition Modeling (FDM) is a popular 3D printing technique that builds objects layer-by-layer using thermoplastic filaments, known for its affordability and ease of use. Stereolithography (SLA) utilizes a laser to cure liquid resin into solid layers, offering high resolution and smooth surface finish. Your choice between FDM and SLA depends on the required detail, material properties, and budget for your project.

Core Principles: How FDM and SLA Work

Fused Deposition Modeling (FDM) operates by extruding thermoplastic filament through a heated nozzle, layer by layer, to build objects based on digital 3D models, relying on material deposition and solidification. Stereolithography (SLA) uses a UV laser to selectively cure liquid photopolymer resin in a vat, solidifying each layer through photopolymerization with precise light exposure. FDM emphasizes mechanical deposition and layering of melted plastics, while SLA focuses on photochemical curing for higher resolution and smoother surface finishes.

Material Compatibility: FDM vs SLA

Fused Deposition Modeling (FDM) primarily uses thermoplastic filaments such as PLA, ABS, and PETG, offering a wide range of material choices suitable for durable prototypes and functional parts. Stereolithography (SLA) employs photopolymer resins that provide high-detail finishes and smooth surfaces but are generally more brittle and limited in mechanical strength compared to FDM materials. When selecting a 3D printing method, consider your project's material requirements, as FDM supports tougher, versatile materials while SLA excels in precision with resin-based options.

Print Quality and Surface Finish Comparison

Fused Deposition Modeling (FDM) typically produces prints with visible layer lines and a rougher surface finish due to the extrusion of thermoplastic filaments, resulting in lower resolution details. Stereolithography (SLA) uses a laser to cure liquid resin, achieving higher resolution and smoother surfaces with finer, more precise details ideal for intricate designs. SLA prints often require less post-processing to achieve a polished finish, while FDM models benefit from sanding and coating to improve surface quality.

Speed and Efficiency: Production Times Analyzed

Fused Deposition Modeling (FDM) generally offers faster production times due to its straightforward layer-by-layer extrusion process, making it ideal for rapid prototyping and larger parts. Stereolithography (SLA) provides higher resolution and surface finish but typically requires longer curing times and post-processing, impacting overall efficiency. Your choice depends on balancing speed with precision requirements for the specific application.

Accuracy and Detail Resolution in FDM and SLA

Fused Deposition Modeling (FDM) offers moderate accuracy with typical layer heights around 100-300 microns, making it suitable for functional prototypes but less ideal for fine detail resolution. Stereolithography (SLA) achieves superior accuracy and detail resolution, often reaching layer heights as fine as 25-50 microns, allowing for highly detailed and smooth surface finishes. SLA's precision results from its use of a laser to cure photopolymer resin, providing intricate geometries beyond the capabilities of FDM's extrusion-based process.

Cost Considerations: Initial and Ongoing Expenses

Fused Deposition Modeling (FDM) printers generally have lower initial costs, often ranging from $200 to $5,000, making them accessible for hobbyists and small businesses, while Stereolithography (SLA) machines typically start at $3,000 and can exceed $10,000 due to more complex laser and resin technology. Ongoing expenses for FDM mainly involve affordable thermoplastic filament, costing $20 to $50 per kilogram, whereas SLA requires specialized resins priced between $150 to $300 per liter, driving up operational costs. Maintenance for SLA printers also tends to be more intensive and expensive, including resin handling and UV curing equipment, which contributes to higher total cost of ownership over time compared to FDM systems.

Applications: Ideal Uses for FDM and SLA

Fused Deposition Modeling (FDM) is ideal for creating functional prototypes, durable parts, and mechanical components due to its cost-effectiveness and ability to use a wide range of thermoplastics. Stereolithography (SLA) excels in producing highly detailed models, intricate designs, and smooth surface finishes, making it perfect for jewelry, dental molds, and complex visual prototypes. Your choice between FDM and SLA depends on whether you prioritize strength and affordability or precision and fine details in your application.

Post-Processing Requirements and Challenges

Fused Deposition Modeling (FDM) requires minimal post-processing, primarily involving support removal and surface sanding to improve finish quality, while Stereolithography (SLA) demands more intensive post-processing such as washing in isopropyl alcohol and UV curing to fully harden resin prints. FDM's challenges include managing stringing and layer adhesion during cleanup, whereas SLA prints are highly sensitive to handling during wet stages, necessitating careful support removal to avoid surface damage. Your choice between FDM and SLA influences the complexity and time commitment of post-processing tasks, impacting overall project workflow and final print quality.

Choosing the Right Technology: FDM vs SLA for Your Needs

Fused Deposition Modeling (FDM) offers cost-effective, durable parts ideal for functional prototypes and large-scale models, while Stereolithography (SLA) excels in producing high-resolution, intricate details suited for fine prototypes and complex designs. Your choice depends on the required precision, material properties, and budget constraints, with FDM favoring strength and affordability and SLA prioritizing surface quality and accuracy. Evaluating project specifications like layer resolution, production speed, and end-use application ensures selecting the optimal 3D printing technology for your needs.

Fused Deposition Modeling (FDM) vs Stereolithography (SLA) Infographic

libmatt.com

libmatt.com