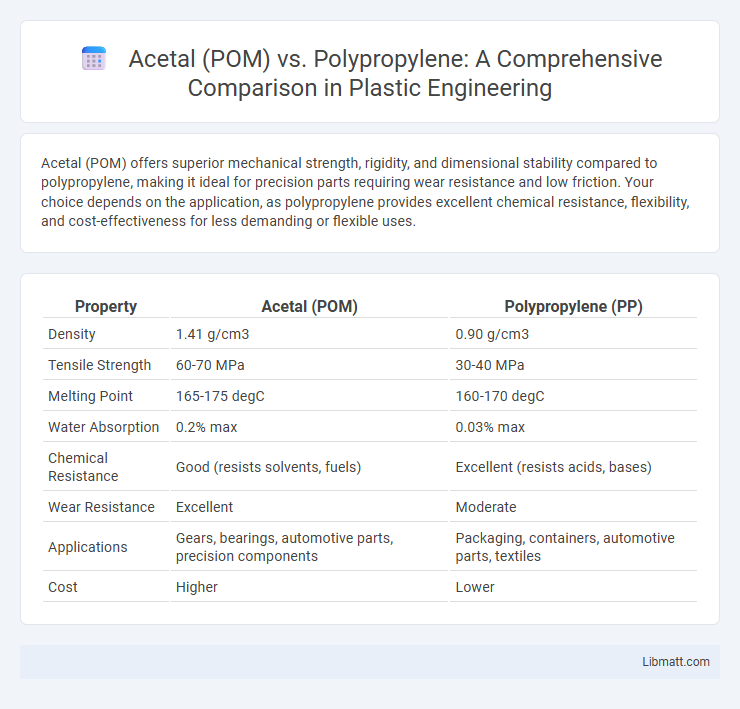

Acetal (POM) offers superior mechanical strength, rigidity, and dimensional stability compared to polypropylene, making it ideal for precision parts requiring wear resistance and low friction. Your choice depends on the application, as polypropylene provides excellent chemical resistance, flexibility, and cost-effectiveness for less demanding or flexible uses.

Table of Comparison

| Property | Acetal (POM) | Polypropylene (PP) |

|---|---|---|

| Density | 1.41 g/cm3 | 0.90 g/cm3 |

| Tensile Strength | 60-70 MPa | 30-40 MPa |

| Melting Point | 165-175 degC | 160-170 degC |

| Water Absorption | 0.2% max | 0.03% max |

| Chemical Resistance | Good (resists solvents, fuels) | Excellent (resists acids, bases) |

| Wear Resistance | Excellent | Moderate |

| Applications | Gears, bearings, automotive parts, precision components | Packaging, containers, automotive parts, textiles |

| Cost | Higher | Lower |

Introduction to Acetal (POM) and Polypropylene

Acetal (POM), known for its high stiffness, low friction, and excellent dimensional stability, is a thermoplastic commonly used in precision parts requiring durability and wear resistance. Polypropylene (PP) offers versatile chemical resistance, low density, and flexibility, making it ideal for packaging, textiles, and automotive components. Both materials exhibit unique properties suitable for distinct engineering and manufacturing applications.

Chemical Structure and Composition

Acetal (POM) is a crystalline thermoplastic composed of repeating oxymethylene units, giving it a highly ordered molecular structure with strong carbon-oxygen bonds that provide excellent stiffness and low friction. Polypropylene consists of long chains of propylene monomers featuring a non-polar hydrocarbon structure with methyl side groups, resulting in a semi-crystalline polymer known for its flexibility and chemical resistance. Your choice between these materials should consider that POM's polar structure offers superior dimensional stability, while polypropylene's composition enhances impact resistance and resistance to acids and bases.

Mechanical Properties Comparison

Acetal (POM) exhibits superior mechanical strength, stiffness, and dimensional stability compared to polypropylene, making it ideal for precision parts that require durability and low friction. Polypropylene offers greater flexibility and impact resistance but has lower tensile strength and rigidity than Acetal. The high fatigue resistance and wear properties of Acetal surpass those of polypropylene, ensuring longer performance life under mechanical stress.

Thermal Resistance and Stability

Acetal (POM) exhibits superior thermal resistance compared to polypropylene, maintaining mechanical properties at continuous use temperatures up to approximately 100-120degC, while polypropylene typically withstands temperatures around 80-100degC. POM's crystalline structure provides enhanced thermal stability, resisting deformation and retaining rigidity under thermal stress, making it suitable for precision parts in higher temperature environments. Polypropylene's lower melting point and semi-crystalline nature result in reduced thermal stability, limiting its use in applications requiring long-term heat exposure.

Wear and Friction Performance

Acetal (POM) exhibits superior wear resistance and lower friction coefficients compared to polypropylene, making it ideal for high-precision mechanical parts and sliding applications. Your choice of POM ensures enhanced durability and reduced maintenance in environments subjected to repetitive motion and frictional stress. Polypropylene, while cost-effective and chemically resistant, generally demonstrates higher friction and faster wear under similar load conditions.

Chemical Resistance and Durability

Acetal (POM) offers superior chemical resistance to solvents such as ketones, esters, and hydrocarbons compared to polypropylene, which is more susceptible to degradation by strong oxidizing agents and some acids. The durability of Acetal is enhanced by its high tensile strength and excellent dimensional stability under mechanical stress, making it ideal for precision components and gears. Polypropylene, while less resistant chemically, excels in flexibility and impact resistance, suitable for applications requiring repeated stress and exposure to mild chemicals.

Applications in Various Industries

Acetal (POM) and Polypropylene serve critical roles across diverse industries due to their distinct material properties. Acetal excels in precision engineering applications, including automotive fuel systems, electrical components, and industrial machinery parts, thanks to its high dimensional stability and low friction. Polypropylene is favored in packaging, medical devices, and consumer goods for its chemical resistance, flexibility, and cost-effectiveness, ensuring your products meet specific application requirements efficiently.

Manufacturing Processes and Machinability

Acetal (POM) is typically produced through polymerization of formaldehyde, resulting in a highly crystalline thermoplastic that exhibits excellent dimensional stability and low friction, making it highly machinable with tight tolerances. Polypropylene is manufactured via chain-growth polymerization of propylene monomers and possesses a semi-crystalline structure, offering moderate machinability but often requiring more careful handling due to its lower stiffness and higher thermal expansion compared to Acetal. Your choice between Acetal and Polypropylene will depend on the precision and surface finish requirements of your components, with Acetal generally preferred for high-accuracy machining and Polypropylene suited for simpler fabrication processes.

Environmental Impact and Recyclability

Acetal (POM) has a denser molecular structure that makes it less biodegradable compared to Polypropylene, which is more environmentally friendly due to its lower carbon footprint and better recyclability. Polypropylene is widely accepted in recycling programs and can be efficiently converted into recycled products, while Acetal's recycling options are limited and often require specialized facilities. Your choice between these materials will influence the environmental impact of your product, with Polypropylene offering a more sustainable lifecycle.

Cost Analysis and Market Availability

Acetal (POM) is generally more expensive than polypropylene due to its superior mechanical properties and chemical resistance, making it a costlier choice for precision parts. Polypropylene offers broader market availability and lower raw material costs, which makes it a popular option for high-volume, budget-sensitive applications. You should consider the trade-off between performance and price when selecting materials for your manufacturing needs.

Acetal (POM) vs Polypropylene Infographic

libmatt.com

libmatt.com