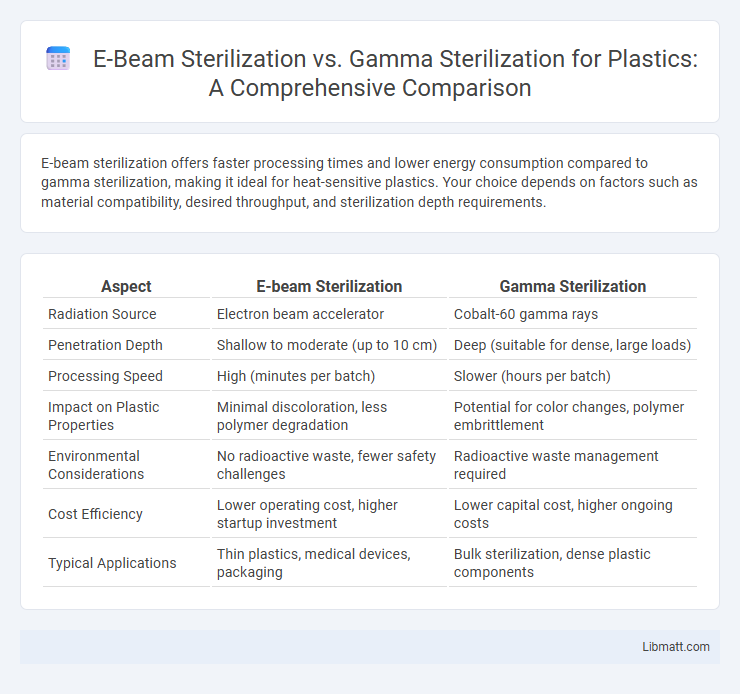

E-beam sterilization offers faster processing times and lower energy consumption compared to gamma sterilization, making it ideal for heat-sensitive plastics. Your choice depends on factors such as material compatibility, desired throughput, and sterilization depth requirements.

Table of Comparison

| Aspect | E-beam Sterilization | Gamma Sterilization |

|---|---|---|

| Radiation Source | Electron beam accelerator | Cobalt-60 gamma rays |

| Penetration Depth | Shallow to moderate (up to 10 cm) | Deep (suitable for dense, large loads) |

| Processing Speed | High (minutes per batch) | Slower (hours per batch) |

| Impact on Plastic Properties | Minimal discoloration, less polymer degradation | Potential for color changes, polymer embrittlement |

| Environmental Considerations | No radioactive waste, fewer safety challenges | Radioactive waste management required |

| Cost Efficiency | Lower operating cost, higher startup investment | Lower capital cost, higher ongoing costs |

| Typical Applications | Thin plastics, medical devices, packaging | Bulk sterilization, dense plastic components |

Introduction to Sterilization Methods for Plastics

E-beam sterilization utilizes high-energy electrons to disrupt microbial DNA, providing a rapid, environmentally friendly method ideal for heat-sensitive plastics. Gamma sterilization employs gamma rays from cobalt-60 sources, offering deep penetration suitable for dense or bulk plastic materials. Both methods ensure effective sterilization while preserving the integrity of various plastic products used in medical, pharmaceutical, and food industries.

Overview of E-beam Sterilization

E-beam sterilization utilizes high-energy electrons to effectively eliminate microbial contaminants from plastic materials, offering rapid processing times and precise dosage control. This method generates minimal heat, preserving the integrity and performance of heat-sensitive plastics compared to gamma sterilization. Your choice of sterilization technique impacts product quality, throughput, and environmental safety considerations in medical and packaging applications.

Overview of Gamma Sterilization

Gamma sterilization uses cobalt-60 as a radiation source to penetrate deeply into plastic materials, effectively eliminating bacteria, viruses, and other pathogens. This method is widely employed for sterilizing medical devices and single-use plastics due to its high sterilization reliability and ability to treat large batches uniformly. However, gamma radiation can cause polymer degradation such as discoloration, embrittlement, or changes in mechanical properties, which must be considered when selecting materials.

Mechanisms of Action: E-beam vs Gamma

E-beam sterilization uses high-energy electrons to disrupt microbial DNA and cellular components through direct ionization, leading to rapid inactivation of contaminants on plastics. Gamma sterilization employs gamma rays from isotopes like Cobalt-60, generating reactive free radicals that cause extensive molecular damage to microorganisms and polymers on plastic surfaces. Both mechanisms effectively sterilize plastics, but E-beam offers precise dose control with minimal material degradation, whereas gamma sterilization provides deep penetration ideal for densely packed or bulky plastic medical devices.

Effect on Plastic Material Properties

E-beam sterilization causes minimal changes to the mechanical and chemical properties of plastics, preserving tensile strength and clarity due to its lower penetration depth and shorter exposure time. Gamma sterilization, while effective, can lead to more significant molecular degradation, including chain scission or cross-linking that may alter plastic flexibility and color. Choosing the appropriate method ensures your plastic products maintain their integrity and performance throughout sterilization.

Processing Speed and Efficiency

E-beam sterilization offers significantly faster processing speeds compared to gamma sterilization, making it ideal for high-throughput plastic manufacturing environments. The immediate on/off capability of e-beam technology enhances operational efficiency by reducing downtime and energy consumption. Your choice between these methods should consider that while gamma sterilization provides deeper penetration for dense plastics, e-beam excels in rapid, efficient surface sterilization applications.

Penetration Depth and Dose Uniformity

E-beam sterilization offers lower penetration depth, typically up to 8 cm, making it suitable for thin or surface-level sterilization of plastics, while gamma sterilization achieves much greater penetration depths, often exceeding 30 cm, enabling effective sterilization of bulkier or densely packed materials. Dose uniformity in gamma sterilization is generally superior due to deep penetration and the ability of gamma rays to scatter uniformly within the material, whereas e-beam sterilization may exhibit dose variation, especially in thicker or irregularly shaped plastic products. The choice between e-beam and gamma sterilization hinges on product thickness, density, and required dose uniformity to ensure effective microbial inactivation without compromising plastic integrity.

Safety and Environmental Considerations

E-beam sterilization offers a safer alternative to gamma sterilization by eliminating radioactive materials, reducing risks associated with radiation exposure and contamination. It requires less shielding and produces no radioactive waste, significantly lowering environmental impact compared to the long-lived radioactive isotopes used in gamma sterilization. Your choice between these methods should consider the balance of operational safety and ecological footprint, with E-beam providing a more environmentally friendly and controlled sterilization process for plastics.

Cost Comparison: E-beam vs Gamma

E-beam sterilization offers lower operational costs due to its faster processing times and reduced energy consumption compared to gamma sterilization, which requires expensive radioactive isotope sources like Cobalt-60. Initial capital investment for gamma sterilization facilities is higher because of extensive shielding and regulatory compliance, whereas e-beam systems are more compact and have lower maintenance costs. Despite e-beam's cost advantages, gamma sterilization remains economically viable for large-scale operations with high throughput demands due to its deeper penetration and consistent dose distribution in thick plastic materials.

Choosing the Right Method for Plastic Sterilization

E-beam sterilization offers precise control and shorter processing times, making it ideal for thermally sensitive plastics requiring minimal degradation. Gamma sterilization penetrates deeper, suitable for thick or densely packed plastic materials but may cause more polymer chain scission and discoloration. Selecting the right method depends on factors like plastic type, product geometry, and desired sterility assurance level to maintain material integrity and performance.

E-beam Sterilization vs Gamma Sterilization for Plastics Infographic

libmatt.com

libmatt.com