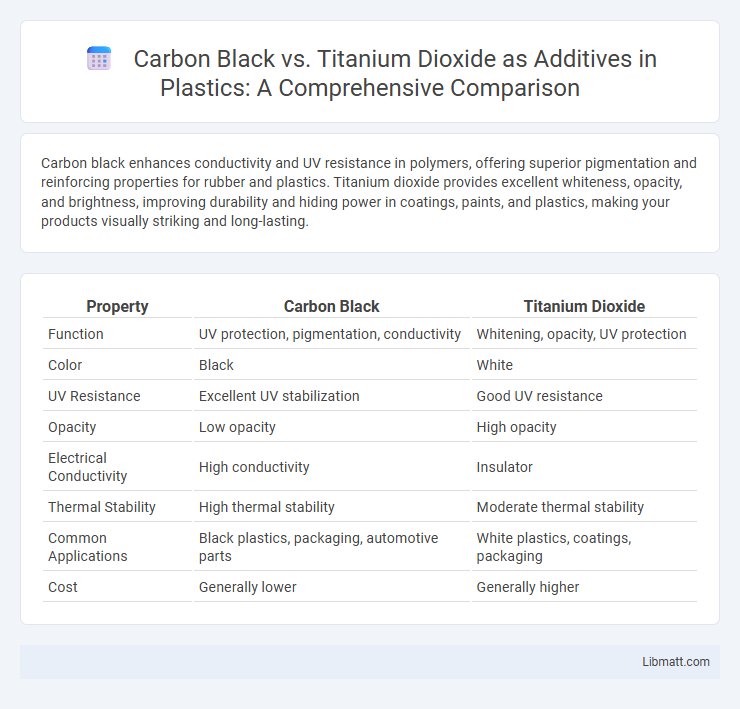

Carbon black enhances conductivity and UV resistance in polymers, offering superior pigmentation and reinforcing properties for rubber and plastics. Titanium dioxide provides excellent whiteness, opacity, and brightness, improving durability and hiding power in coatings, paints, and plastics, making your products visually striking and long-lasting.

Table of Comparison

| Property | Carbon Black | Titanium Dioxide |

|---|---|---|

| Function | UV protection, pigmentation, conductivity | Whitening, opacity, UV protection |

| Color | Black | White |

| UV Resistance | Excellent UV stabilization | Good UV resistance |

| Opacity | Low opacity | High opacity |

| Electrical Conductivity | High conductivity | Insulator |

| Thermal Stability | High thermal stability | Moderate thermal stability |

| Common Applications | Black plastics, packaging, automotive parts | White plastics, coatings, packaging |

| Cost | Generally lower | Generally higher |

Introduction to Pigment Additives

Carbon black and titanium dioxide serve as essential pigment additives in various industries, offering distinct optical and functional properties. Carbon black, a fine black powder, provides deep coloration, UV protection, and conductivity enhancement, widely used in plastics, rubber, and coatings. Titanium dioxide is prized for its exceptional whiteness, opacity, and brightness, making it a key additive in paints, plastics, and cosmetics to improve color vibrancy and durability.

Chemical Structure: Carbon Black vs Titanium Dioxide

Carbon black consists of fine particles of elemental carbon with an amorphous structure, characterized by a high surface area and complex aggregate morphology that enhances its reinforcing properties in polymers. Titanium dioxide is a crystalline metal oxide composed of TiO2 molecules arranged in rutile or anatase crystal structures, providing excellent opacity and UV resistance in coatings and plastics. The fundamental chemical difference lies in carbon black's pure carbon composition versus titanium dioxide's metal oxide form, influencing their distinct functional roles as additives.

Manufacturing Processes of Both Additives

Carbon black is produced through the incomplete combustion or thermal decomposition of hydrocarbons, typically utilizing furnace black or thermal black processes that generate fine carbon particles with high surface area. Titanium dioxide is primarily manufactured via the sulfate process or the more environmentally friendly chloride process, where titanium-containing ores are chemically processed to yield high-purity TiO2 pigments. Your choice between these additives should consider not only the desired physical properties but also the environmental and cost implications associated with their respective manufacturing methods.

Optical Properties and Coloration Effects

Carbon black and titanium dioxide exhibit stark contrasts in their optical properties and coloration effects as additives. Carbon black provides deep black pigmentation with high light absorption, improving opacity without reflecting light, making Your product darker and more UV resistant. Conversely, titanium dioxide offers exceptional whiteness and brightness, scattering visible light to enhance reflectivity and opacity, ideal for achieving vivid, bright colorations in coatings or polymers.

Performance in UV Protection

Carbon black outperforms titanium dioxide in UV protection due to its superior ability to absorb a broad spectrum of ultraviolet radiation, making it highly effective in preventing polymer degradation and color fading. Titanium dioxide primarily acts as a UV reflector and scatterer but is less efficient in absorbing UV rays, particularly in the UVA range. This makes carbon black the preferred additive for enhanced durability and extended material lifespan in UV-exposed applications.

Applications in Polymers and Coatings

Carbon black enhances UV resistance, conductivity, and color depth in polymers and coatings, making it essential for automotive parts, tires, and industrial paints. Titanium dioxide provides superior opacity, whiteness, and brightness, widely used in decorative paints, plastics, and food packaging films. Both additives improve durability and performance, with carbon black preferred for black pigmentation and electrical properties, while titanium dioxide is favored for bright, opaque finishes.

Environmental Impact and Sustainability

Carbon black, derived primarily from fossil fuels, has a significant environmental footprint due to high carbon emissions and non-renewable resource consumption, raising concerns about sustainability. In contrast, titanium dioxide, often produced via energy-intensive mining and chemical processes, poses lesser carbon emissions but contributes to environmental challenges like water pollution and resource depletion. Sustainable alternatives focus on improving production efficiency, recycling waste materials, and developing bio-based or low-impact additives to mitigate ecological harm in both cases.

Cost Comparison and Market Availability

Carbon black generally offers a lower cost per unit compared to titanium dioxide, making it an economical choice for large-scale industrial applications. Titanium dioxide's higher price reflects its superior opacity and brightness, which are critical in premium coatings and plastics. Your decision depends on budget constraints and specific performance requirements, with carbon black widely available in global markets and titanium dioxide experiencing occasional supply fluctuations due to complex manufacturing processes.

Health and Safety Considerations

Carbon black, primarily composed of elemental carbon particles, poses inhalation risks linked to respiratory issues and potential carcinogenic effects, necessitating proper ventilation and protective respiratory equipment during handling. Titanium dioxide, widely used as a pigment, is classified as a possible carcinogen when inhaled in its nanoparticle form, prompting the implementation of exposure limits and dust control measures in workplaces. Both additives require stringent occupational safety protocols to mitigate health hazards, including the use of personal protective equipment and adherence to regulatory guidelines established by entities such as OSHA and NIOSH.

Selecting the Right Additive for Your Application

Carbon black offers superior UV resistance and conductivity, making it ideal for applications requiring durability and electrical properties, while titanium dioxide excels in enhancing opacity, brightness, and whiteness in coatings and plastics. Your selection should consider the specific performance needs such as color impact, weathering stability, and compatibility with the base material. Optimizing additive choice ensures improved product lifespan, appearance, and functionality tailored to your application's demands.

Carbon black vs titanium dioxide (as additives) Infographic

libmatt.com

libmatt.com