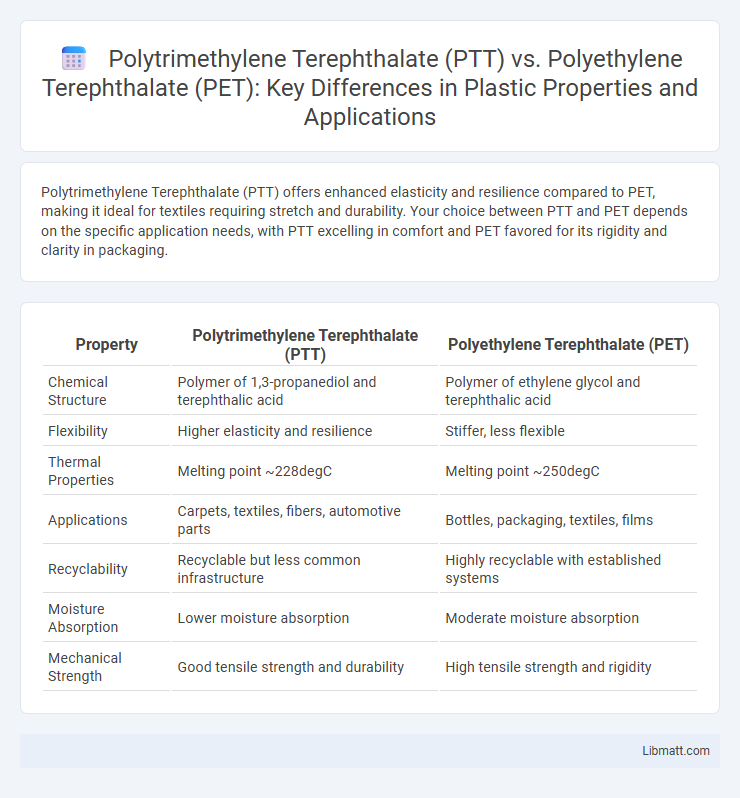

Polytrimethylene Terephthalate (PTT) offers enhanced elasticity and resilience compared to PET, making it ideal for textiles requiring stretch and durability. Your choice between PTT and PET depends on the specific application needs, with PTT excelling in comfort and PET favored for its rigidity and clarity in packaging.

Table of Comparison

| Property | Polytrimethylene Terephthalate (PTT) | Polyethylene Terephthalate (PET) |

|---|---|---|

| Chemical Structure | Polymer of 1,3-propanediol and terephthalic acid | Polymer of ethylene glycol and terephthalic acid |

| Flexibility | Higher elasticity and resilience | Stiffer, less flexible |

| Thermal Properties | Melting point ~228degC | Melting point ~250degC |

| Applications | Carpets, textiles, fibers, automotive parts | Bottles, packaging, textiles, films |

| Recyclability | Recyclable but less common infrastructure | Highly recyclable with established systems |

| Moisture Absorption | Lower moisture absorption | Moderate moisture absorption |

| Mechanical Strength | Good tensile strength and durability | High tensile strength and rigidity |

Introduction to Polytrimethylene Terephthalate (PTT) and PET

Polytrimethylene Terephthalate (PTT) is a type of polyester known for its excellent elasticity, resilience, and softness, making it ideal for textiles and carpet fibers. Polyethylene Terephthalate (PET) is a widely used polyester with high tensile strength, durability, and chemical resistance, commonly found in packaging, bottles, and synthetic fibers. Your choice between PTT and PET depends on specific applications requiring flexibility and comfort versus strength and rigidity.

Chemical Structure: PTT vs PET

Polytrimethylene Terephthalate (PTT) differs from Polyethylene Terephthalate (PET) primarily in its chemical structure, where PTT incorporates a three-carbon 1,3-propanediol segment instead of the two-carbon ethylene glycol found in PET. This structural variation imparts PTT with enhanced elasticity, resilience, and a softer hand feel compared to the more rigid, crystalline nature of PET. Your choice between PTT and PET could influence fabric performance, durability, and comfort based on these intrinsic polymer differences.

Production Processes and Raw Materials

Polytrimethylene Terephthalate (PTT) is produced through polycondensation of 1,3-propanediol with terephthalic acid or its derivatives, distinguishing it from Polyethylene Terephthalate (PET), which is synthesized using ethylene glycol and terephthalic acid. The raw material for PTT, 1,3-propanediol, is often derived from renewable resources such as corn glucose, supporting bio-based production routes, whereas PET primarily relies on petrochemical-based ethylene glycol. Differences in the polymerization process and feedstock sources impact the molecular structure and performance characteristics of PTT and PET fibers.

Mechanical Properties Comparison

Polytrimethylene Terephthalate (PTT) offers superior elongation at break and better resilience compared to Polyethylene Terephthalate (PET), making it more suitable for applications requiring enhanced flexibility and impact resistance. PET exhibits higher tensile strength and stiffness, which contributes to its widespread use in rigid containers and fibers demanding structural integrity. The choice between PTT and PET depends on the specific mechanical property requirements, such as flexibility for PTT or tensile strength for PET.

Dyeability and Color Fastness

Polytrimethylene Terephthalate (PTT) exhibits superior dyeability compared to Polyethylene Terephthalate (PET), allowing for richer and more vibrant colors with less dye usage. PTT fibers demonstrate enhanced color fastness, maintaining their hue and resisting fading better through repeated washing and exposure to light. Your textile products will benefit from PTT's ability to achieve deep, lasting colors ideal for fashion and interior applications.

Environmental Impact and Sustainability

Polytrimethylene Terephthalate (PTT) offers enhanced sustainability compared to PET due to its partially bio-based production process, reducing reliance on fossil fuels and lowering carbon emissions. Both polymers are recyclable, but PTT's renewable feedstock from corn sugar promotes a smaller environmental footprint throughout its lifecycle. Your choice of PTT supports a shift towards greener materials and contributes to reducing plastic pollution and greenhouse gas impacts.

Applications in Textile and Industrial Sectors

Polytrimethylene Terephthalate (PTT) offers superior elasticity and softness compared to Polyethylene Terephthalate (PET), making it highly favored in the textile industry for comfortable, durable apparel, carpets, and upholstery fabrics. PET's strength, chemical resistance, and moisture-wicking properties drive its widespread use in industrial applications such as packaging, automotive parts, and tire reinforcements. Your selection between PTT and PET should consider the balance between softness and mechanical toughness required by your specific textile or industrial project.

Performance in End-Use Products

Polytrimethylene Terephthalate (PTT) offers superior elasticity and resilience compared to PET, enhancing comfort and durability in textiles and carpeting. Your end-use products benefit from PTT's excellent stain resistance and softness, making it ideal for apparel and home furnishings. PET, while stronger and more rigid, excels in packaging applications due to its high tensile strength and chemical resistance.

Cost Analysis and Market Trends

Polytrimethylene Terephthalate (PTT) typically incurs higher production costs compared to Polyethylene Terephthalate (PET) due to its more complex polymerization process and lower raw material availability. Despite this, PTT's superior elasticity and softness drive increasing demand in niche markets such as textiles and packaging, fostering steady growth in its global market share. Your decision to invest in PTT or PET should weigh cost differences against evolving market trends and application-specific performance requirements.

Future Prospects and Innovations

Polytrimethylene Terephthalate (PTT) offers promising future prospects with its enhanced elasticity, stain resistance, and eco-friendly production methods compared to PET. Innovations in PTT fiber technology focus on improving durability and dyeing techniques, making it a preferred material in sustainable textile and automotive industries. Your adoption of PTT-based products supports advancing bio-based polymer applications and reducing dependence on traditional PET plastics.

Polytrimethylene Terephthalate (PTT) vs PET Infographic

libmatt.com

libmatt.com