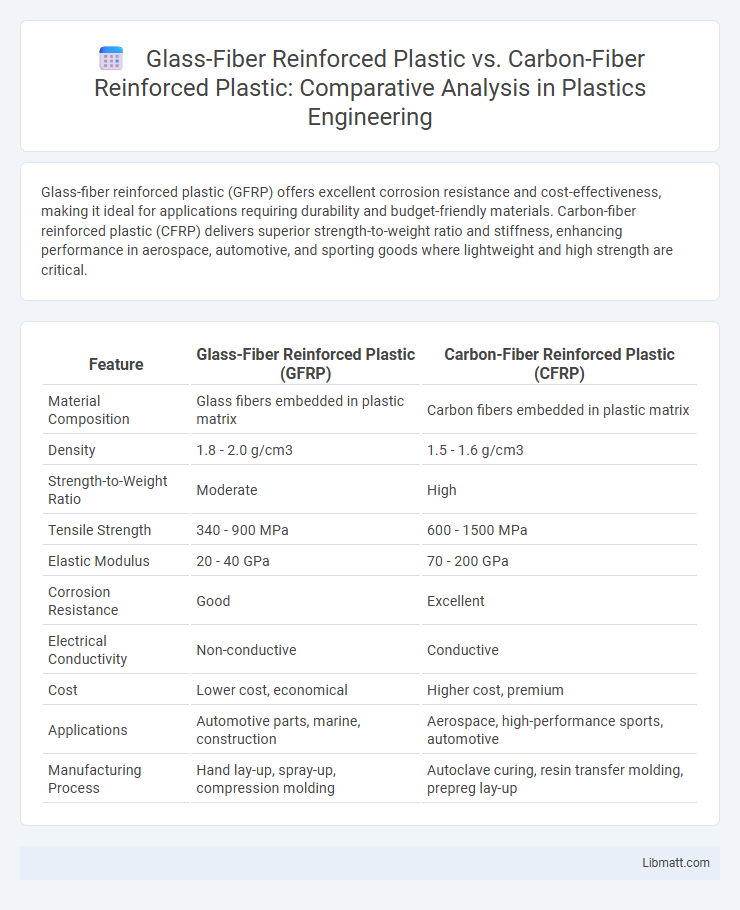

Glass-fiber reinforced plastic (GFRP) offers excellent corrosion resistance and cost-effectiveness, making it ideal for applications requiring durability and budget-friendly materials. Carbon-fiber reinforced plastic (CFRP) delivers superior strength-to-weight ratio and stiffness, enhancing performance in aerospace, automotive, and sporting goods where lightweight and high strength are critical.

Table of Comparison

| Feature | Glass-Fiber Reinforced Plastic (GFRP) | Carbon-Fiber Reinforced Plastic (CFRP) |

|---|---|---|

| Material Composition | Glass fibers embedded in plastic matrix | Carbon fibers embedded in plastic matrix |

| Density | 1.8 - 2.0 g/cm3 | 1.5 - 1.6 g/cm3 |

| Strength-to-Weight Ratio | Moderate | High |

| Tensile Strength | 340 - 900 MPa | 600 - 1500 MPa |

| Elastic Modulus | 20 - 40 GPa | 70 - 200 GPa |

| Corrosion Resistance | Good | Excellent |

| Electrical Conductivity | Non-conductive | Conductive |

| Cost | Lower cost, economical | Higher cost, premium |

| Applications | Automotive parts, marine, construction | Aerospace, high-performance sports, automotive |

| Manufacturing Process | Hand lay-up, spray-up, compression molding | Autoclave curing, resin transfer molding, prepreg lay-up |

Introduction to Reinforced Plastics

Reinforced plastics combine a polymer matrix with fibers to enhance mechanical properties such as strength, stiffness, and durability. Glass-Fiber Reinforced Plastic (GFRP) utilizes glass fibers known for cost-effectiveness, corrosion resistance, and electrical insulation, making it widely used in automotive, construction, and marine industries. Carbon-Fiber Reinforced Plastic (CFRP) incorporates carbon fibers that provide superior tensile strength, high stiffness, and lightweight characteristics, making it ideal for aerospace, high-performance sports equipment, and advanced engineering applications.

What is Glass-Fiber Reinforced Plastic (GFRP)?

Glass-Fiber Reinforced Plastic (GFRP) is a composite material consisting of a polymer matrix reinforced with fine glass fibers, providing high strength and durability while being lightweight. It offers excellent corrosion resistance and electrical insulation properties, making it ideal for applications in construction, automotive, and marine industries. Your choice of GFRP can enhance product longevity and reduce maintenance costs due to its robust mechanical performance and environmental resilience.

What is Carbon-Fiber Reinforced Plastic (CFRP)?

Carbon-Fiber Reinforced Plastic (CFRP) is a composite material consisting of carbon fibers embedded in a polymer matrix, known for its exceptional strength-to-weight ratio and rigidity. CFRP offers superior mechanical performance compared to Glass-Fiber Reinforced Plastic (GFRP), making it ideal for aerospace, automotive, and high-performance sports equipment applications. When considering your project's weight and durability requirements, CFRP delivers unmatched stiffness and fatigue resistance while maintaining minimal weight.

Material Properties: GFRP vs CFRP

Glass-Fiber Reinforced Plastic (GFRP) exhibits moderate tensile strength and excellent corrosion resistance, making it suitable for cost-effective and lightweight structural applications. Carbon-Fiber Reinforced Plastic (CFRP) offers superior tensile strength, stiffness, and fatigue resistance, with significantly lower density, providing enhanced performance in aerospace and high-performance automotive industries. GFRP is generally more flexible and less brittle compared to CFRP, which is characterized by its higher modulus of elasticity and greater impact sensitivity.

Strength and Weight Comparison

Glass-Fiber Reinforced Plastic (GFRP) offers a strength-to-weight ratio suitable for many industrial applications, with tensile strengths typically ranging from 200 to 600 MPa and densities around 1.8-2.0 g/cm3. Carbon-Fiber Reinforced Plastic (CFRP) exhibits significantly higher tensile strength, often between 600 to 1500 MPa, combined with a lower density of approximately 1.6 g/cm3, resulting in superior strength-to-weight performance. This makes CFRP the preferred choice for high-performance industries where minimizing weight without compromising strength is critical, such as aerospace and automotive racing.

Durability and Corrosion Resistance

Glass-Fiber Reinforced Plastic (GFRP) offers excellent corrosion resistance, making it ideal for environments exposed to moisture and chemicals, while Carbon-Fiber Reinforced Plastic (CFRP) provides superior durability with higher tensile strength and fatigue resistance. Although CFRP is generally more resistant to mechanical wear and stress, GFRP maintains its integrity better in highly corrosive conditions without significant degradation. Your choice between GFRP and CFRP should consider the specific environmental exposure and mechanical demands to optimize longevity and performance.

Cost Analysis and Affordability

Glass-Fiber Reinforced Plastic (GFRP) generally offers a more cost-effective solution compared to Carbon-Fiber Reinforced Plastic (CFRP), with GFRP materials priced significantly lower due to less expensive raw materials and manufacturing processes. The affordability of GFRP makes it suitable for applications where budget constraints are critical but moderate strength and durability are acceptable. Your choice between these composites should consider the balance between cost savings with GFRP and the superior performance and higher expense associated with CFRP.

Common Applications of GFRP and CFRP

Glass-Fiber Reinforced Plastic (GFRP) is commonly utilized in construction, automotive components, and marine industries due to its cost-effectiveness and excellent corrosion resistance. Carbon-Fiber Reinforced Plastic (CFRP) finds widespread applications in aerospace, high-performance sporting goods, and luxury automotive parts, prized for its superior strength-to-weight ratio and stiffness. Both materials are integral in manufacturing lightweight, durable structures where specific mechanical properties dictate material choice.

Sustainability and Environmental Impact

Glass-Fiber Reinforced Plastic (GFRP) typically has a lower environmental impact during production due to less energy-intensive manufacturing processes compared to Carbon-Fiber Reinforced Plastic (CFRP). However, CFRP offers superior durability and a longer lifespan, reducing the need for frequent replacements and lowering overall resource consumption. Your decision between these materials should weigh the trade-offs between production emissions and the potential for extended product life to maximize sustainability benefits.

Which Material to Choose: GFRP or CFRP?

Choosing between Glass-Fiber Reinforced Plastic (GFRP) and Carbon-Fiber Reinforced Plastic (CFRP) depends on specific performance and cost requirements, with CFRP offering superior strength-to-weight ratio, stiffness, and fatigue resistance ideal for aerospace and high-performance automotive applications. GFRP provides excellent corrosion resistance, lower cost, and good mechanical properties, making it suitable for construction, marine, and general automotive uses where budget constraints and environmental durability are critical. Weight-sensitive projects demanding high tensile strength typically favor CFRP, while applications requiring economic efficiency and impact resistance often choose GFRP.

Glass-Fiber Reinforced Plastic vs Carbon-Fiber Reinforced Plastic Infographic

libmatt.com

libmatt.com