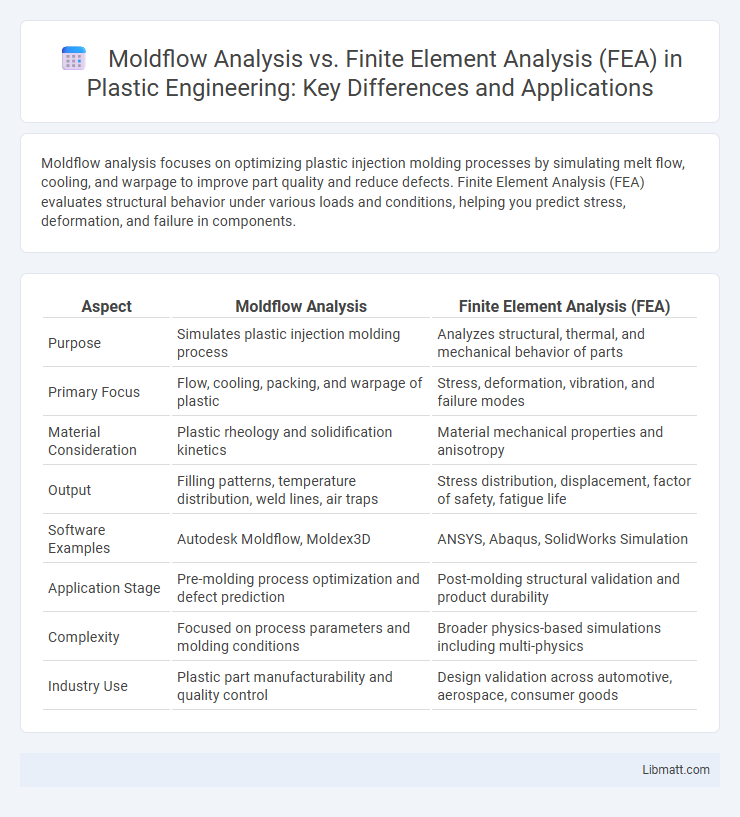

Moldflow analysis focuses on optimizing plastic injection molding processes by simulating melt flow, cooling, and warpage to improve part quality and reduce defects. Finite Element Analysis (FEA) evaluates structural behavior under various loads and conditions, helping you predict stress, deformation, and failure in components.

Table of Comparison

| Aspect | Moldflow Analysis | Finite Element Analysis (FEA) |

|---|---|---|

| Purpose | Simulates plastic injection molding process | Analyzes structural, thermal, and mechanical behavior of parts |

| Primary Focus | Flow, cooling, packing, and warpage of plastic | Stress, deformation, vibration, and failure modes |

| Material Consideration | Plastic rheology and solidification kinetics | Material mechanical properties and anisotropy |

| Output | Filling patterns, temperature distribution, weld lines, air traps | Stress distribution, displacement, factor of safety, fatigue life |

| Software Examples | Autodesk Moldflow, Moldex3D | ANSYS, Abaqus, SolidWorks Simulation |

| Application Stage | Pre-molding process optimization and defect prediction | Post-molding structural validation and product durability |

| Complexity | Focused on process parameters and molding conditions | Broader physics-based simulations including multi-physics |

| Industry Use | Plastic part manufacturability and quality control | Design validation across automotive, aerospace, consumer goods |

Introduction to Moldflow Analysis and Finite Element Analysis (FEA)

Moldflow Analysis simulates the plastic injection molding process to optimize mold design, troubleshoot defects, and predict material flow behavior, ensuring efficient production and high-quality parts. Finite Element Analysis (FEA) evaluates structural performance by dividing components into finite elements to analyze stress, strain, and deformation under various loading conditions. Both techniques leverage computational algorithms but target different phases of product development, with Moldflow centered on manufacturing feasibility and FEA focused on functional durability and strength.

Fundamental Differences Between Moldflow and FEA

Moldflow analysis specializes in simulating the plastic injection molding process, predicting material flow, cooling, shrinkage, and potential defects in molded parts. Finite Element Analysis (FEA) focuses on structural, thermal, and mechanical behavior simulations by dividing the object into discrete elements to solve complex physical problems. Your choice between Moldflow and FEA depends on whether you need to optimize manufacturing processes or assess the performance and durability of the final product.

Core Principles: How Moldflow Analysis Works

Moldflow analysis utilizes computational fluid dynamics to simulate the plastic injection molding process, predicting material flow, cooling, and potential defects such as warpage and sink marks. It models polymer melt behavior under pressure and temperature conditions within the mold cavity to optimize cycle times and part quality. Finite element analysis (FEA), by contrast, primarily evaluates structural behavior through mesh-based stress, strain, and deformation computations without directly simulating the material flow and cooling phenomena specific to injection molding.

Core Principles: How FEA Works

Finite Element Analysis (FEA) divides a complex structure into smaller, manageable elements to simulate physical behaviors under various conditions, using mathematical equations to predict stress, strain, and deformation. In comparison, Moldflow analysis specifically models the plastic injection molding process to optimize material flow, cooling, and shrinking, ensuring part quality and manufacturability. Your understanding of FEA's core principles enables effective application in structural analysis, complementing Moldflow's process-focused simulations for comprehensive product development.

Application Areas: Moldflow vs. FEA

Moldflow analysis specializes in simulating the plastic injection molding process, optimizing mold design, predicting material flow, cooling, and potential defects such as warpage or weld lines. Finite Element Analysis (FEA) offers a broader application scope, including structural, thermal, and dynamic analysis across various engineering fields to evaluate stress, strain, and deformation under different loading conditions. Your choice depends on the specific phase of product development: Moldflow for manufacturing process optimization and FEA for structural performance and durability assessment.

Types of Problems Addressed by Moldflow and FEA

Moldflow analysis specializes in simulating plastic injection molding processes, focusing on issues such as flow behavior, cooling patterns, and potential defects like warpage and sink marks in molded parts. Finite Element Analysis (FEA) addresses a broader range of structural and thermal problems, including stress distribution, deformation, vibration, and heat transfer in various materials and components. Your choice depends on whether you need detailed insights into molding process optimization (Moldflow) or comprehensive mechanical performance evaluation (FEA).

Key Advantages and Limitations of Moldflow Analysis

Moldflow analysis excels in simulating plastic injection molding processes by predicting polymer flow, cooling rates, and potential defects such as warpage and sink marks, providing critical insights to optimize mold design and reduce manufacturing costs. Its primary limitation lies in its focus on the molding phase, lacking the broader structural and stress analysis capabilities available in finite element analysis (FEA), which assesses mechanical performance under various load conditions. You should leverage Moldflow analysis for detailed injection molding process optimization while complementing it with FEA to ensure comprehensive product durability and functionality validation.

Key Advantages and Limitations of Finite Element Analysis

Finite Element Analysis (FEA) offers detailed insights into stress, strain, and deformation by simulating physical behavior under various loads, making it ideal for structural analysis and complex mechanical systems. Its key advantages include high accuracy in predicting mechanical performance and versatility across different materials and conditions. However, FEA requires substantial computational resources and expertise to set up models correctly, and interpretation of results may be challenging without specialized knowledge, affecting its practical application in real-time production decisions.

Integrating Moldflow and FEA for Enhanced Product Design

Integrating Moldflow analysis with finite element analysis (FEA) enhances product design by providing comprehensive insights into both plastic injection molding and structural performance. Moldflow simulates the filling, cooling, and warpage of molded parts, while FEA assesses stresses, strains, and mechanical behavior under load. Combining these technologies enables engineers to predict manufacturing defects and optimize part geometry concurrently, reducing prototyping costs and improving product reliability.

Choosing the Right Analysis Method for Your Engineering Needs

Moldflow analysis specializes in simulating plastic injection molding processes, predicting flow patterns, cooling rates, and potential defects to optimize mold design and manufacturing efficiency. Finite Element Analysis (FEA) provides detailed structural, thermal, and mechanical stress evaluations across a broad range of engineering applications, including complex load and deformation scenarios. Selecting between Moldflow analysis and FEA depends on project goals: Moldflow is essential for enhancing polymer part fabrication, while FEA offers comprehensive assessment for product durability and performance under operational conditions.

Moldflow analysis vs finite element analysis (FEA) Infographic

libmatt.com

libmatt.com