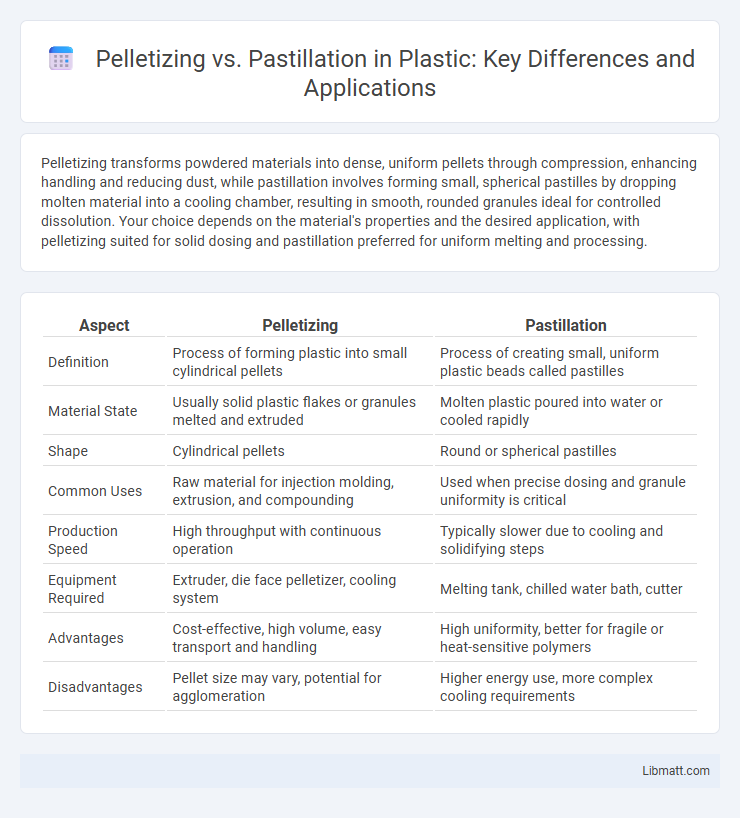

Pelletizing transforms powdered materials into dense, uniform pellets through compression, enhancing handling and reducing dust, while pastillation involves forming small, spherical pastilles by dropping molten material into a cooling chamber, resulting in smooth, rounded granules ideal for controlled dissolution. Your choice depends on the material's properties and the desired application, with pelletizing suited for solid dosing and pastillation preferred for uniform melting and processing.

Table of Comparison

| Aspect | Pelletizing | Pastillation |

|---|---|---|

| Definition | Process of forming plastic into small cylindrical pellets | Process of creating small, uniform plastic beads called pastilles |

| Material State | Usually solid plastic flakes or granules melted and extruded | Molten plastic poured into water or cooled rapidly |

| Shape | Cylindrical pellets | Round or spherical pastilles |

| Common Uses | Raw material for injection molding, extrusion, and compounding | Used when precise dosing and granule uniformity is critical |

| Production Speed | High throughput with continuous operation | Typically slower due to cooling and solidifying steps |

| Equipment Required | Extruder, die face pelletizer, cooling system | Melting tank, chilled water bath, cutter |

| Advantages | Cost-effective, high volume, easy transport and handling | High uniformity, better for fragile or heat-sensitive polymers |

| Disadvantages | Pellet size may vary, potential for agglomeration | Higher energy use, more complex cooling requirements |

Introduction to Pelletizing and Pastillation

Pelletizing involves compressing powdered materials into uniform, dense pellets, improving handling and reducing dust generation in industries such as pharmaceuticals and agriculture. Pastillation, by contrast, entails forming small, drop-shaped solids through a controlled cooling or solidification process, commonly used for substances like resins and waxes. Both methods enhance material usability but differ in technique and application specificity.

Overview of Pelletizing Process

The pelletizing process involves compressing fine powders into uniform, dense, and spherical pellets through mechanical agglomeration, typically using a disc pelletizer or drum pelletizer. This method improves material handling, reduces dust, and enhances product uniformity by promoting particle cohesion under controlled moisture and binder conditions. Pelletizing is widely used in industries such as pharmaceuticals, fertilizers, and metallurgy to produce consistent pellet sizes that improve downstream processing and application efficiency.

Overview of Pastillation Process

Pastillation is a specialized agglomeration technique that transforms fine powders or molten materials into uniform, small, cylindrical pellets by dropping droplets onto a cooled surface where they solidify rapidly. This process enhances material handling, reduces dust generation, and improves flowability compared to conventional pelletizing methods. Your choice of pastillation can optimize product quality when consistent pellet size and shape are critical for downstream processing.

Key Differences Between Pelletizing and Pastillation

Pelletizing produces larger, uniform pellets typically ranging from 3 to 20 mm, ideal for ease of handling and controlled release in industrial applications. Pastillation creates smaller, often irregularly shaped pastilles, generally under 3 mm, enhancing solubility and surface area for faster processing. Your choice between pelletizing and pastillation depends on desired product size, dissolution rate, and application requirements.

Material Suitability for Pelletizing and Pastillation

Pelletizing is ideal for materials with good binding properties and moisture content, such as biomass, minerals, and feedstocks, allowing efficient compression into uniform pellets. Pastillation suits thermoplastic and resinous materials that can be melted and solidified into small, uniform pastilles, ensuring consistent size and shape. Your choice depends on the material's physical state and processing compatibility, maximizing product quality and process efficiency.

Equipment and Technology Comparison

Pelletizing equipment typically involves disc pelletizers or drum pelletizers, which use rotating surfaces to agglomerate fine powders into dense, uniform pellets through layering and compaction. Pastillation technology employs melt or solution pastillators, where molten or slurry material is dropped onto a cooling surface or into a cooling medium, forming small, spherical pastilles with consistent size. Pelletizers offer greater control over pellet density and size distribution, while pastillators excel in producing free-flowing, low-attrition pastilles ideal for applications requiring rapid dissolution or precise dosing.

Efficiency and Throughput Analysis

Pelletizing offers higher throughput due to continuous processing and superior particle uniformity, enhancing downstream handling and product quality. Pastillation provides more precise control over drop size and shape, benefiting products requiring exact specifications but generally has lower production rates. Efficiency in pelletizing is optimized through improved energy utilization and minimized waste, while pastillation's batch nature may increase energy consumption and cycle times.

Product Quality and Uniformity

Pelletizing produces larger, denser granules with consistent size, enhancing product uniformity and reducing dust generation, which improves handling and downstream processing. Pastillation yields smaller, more uniform beads with smooth surfaces, ideal for applications requiring precise dosing and rapid dissolution. Quality control in pelletizing ensures robustness for mechanical stress, while pastillation emphasizes uniform shape and size for consistent performance in pharmaceutical and food industries.

Environmental and Safety Considerations

Pelletizing produces uniformly sized pellets with less dust generation, reducing airborne particulate matter and improving workplace air quality compared to pastillation, which can release higher levels of volatile organic compounds (VOCs) due to melting and solidification processes. Pelletizing also lowers the risk of ignition and explosion hazards by minimizing fines and static charge accumulation, enhancing operational safety in manufacturing environments. Choosing pelletizing can help you meet stricter environmental regulations and maintain safer handling conditions for raw materials and finished products.

Cost Factors and Economic Impact

Pelletizing generally incurs higher initial equipment costs but offers lower operational expenses due to energy efficiency and consistent product quality, impacting overall production economics favorably. Pastillation involves simpler machinery with lower upfront investment but often results in higher waste and reduced throughput, leading to increased per-unit costs over time. Your choice depends on balancing capital expenditure with long-term economic benefits, optimizing cost factors aligned with production scale and material properties.

Pelletizing vs pastillation Infographic

libmatt.com

libmatt.com