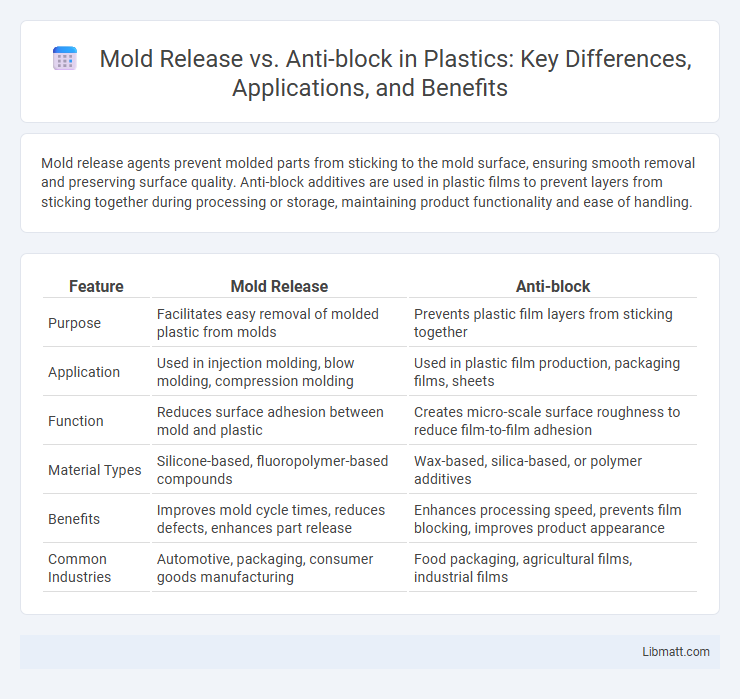

Mold release agents prevent molded parts from sticking to the mold surface, ensuring smooth removal and preserving surface quality. Anti-block additives are used in plastic films to prevent layers from sticking together during processing or storage, maintaining product functionality and ease of handling.

Table of Comparison

| Feature | Mold Release | Anti-block |

|---|---|---|

| Purpose | Facilitates easy removal of molded plastic from molds | Prevents plastic film layers from sticking together |

| Application | Used in injection molding, blow molding, compression molding | Used in plastic film production, packaging films, sheets |

| Function | Reduces surface adhesion between mold and plastic | Creates micro-scale surface roughness to reduce film-to-film adhesion |

| Material Types | Silicone-based, fluoropolymer-based compounds | Wax-based, silica-based, or polymer additives |

| Benefits | Improves mold cycle times, reduces defects, enhances part release | Enhances processing speed, prevents film blocking, improves product appearance |

| Common Industries | Automotive, packaging, consumer goods manufacturing | Food packaging, agricultural films, industrial films |

Understanding Mold Release Agents

Mold release agents are specialized chemicals applied to molds to facilitate the easy removal of finished products without damaging surfaces. Unlike anti-block agents, which prevent sticking between film layers during processing and storage, mold release agents create a barrier that reduces adhesion between the mold and the molded material. Common mold release agents include silicone-based, wax-based, and semi-permanent coatings tailored for industries like plastics, rubber, and composites.

What Are Anti-block Additives?

Anti-block additives are specialized compounds incorporated into plastic films to prevent layers from sticking together during storage and handling, ensuring easy separation and smooth processing. These additives modify the surface properties by creating microscopic roughness or reducing surface energy, enhancing the functionality of your packaging materials. Unlike mold release agents, which facilitate part removal from molds, anti-block additives specifically address the challenge of maintaining film clarity and preventing blocking in multilayer applications.

Key Differences Between Mold Release and Anti-block

Mold release agents are designed to prevent materials from sticking to molds during manufacturing, ensuring easy separation and preserving surface finish quality. Anti-block additives, on the other hand, are incorporated into polymers to reduce surface tackiness and prevent layers from adhering to each other during storage and processing. The key difference lies in their primary function: mold release facilitates mold removal, while anti-block maintains product flowability and surface integrity in stacked or rolled materials.

Applications in Manufacturing Processes

Mold release agents are extensively used in injection molding and casting processes to prevent adhesion between the molded part and the mold, facilitating smooth demolding and preserving surface integrity. Anti-block additives are primarily incorporated into plastic films and sheets during extrusion or blow molding to prevent layers from sticking, ensuring easy handling and processing in packaging and labeling applications. Both agents enhance manufacturing efficiency but target different issues: mold release focuses on part separation, while anti-block addresses product layer separation.

Chemical Composition Comparison

Mold release agents typically contain silicone oils, fatty acids, or synthetic polymers designed to prevent adhesion between the mold surface and the product, enhancing demolding efficiency. Anti-block additives are primarily composed of fine particles such as silica, talc, or waxes that create a microscopic barrier between plastic layers to reduce blocking during processing and storage. Understanding the chemical composition differences helps you select the correct treatment for either facilitating mold release or preventing film sticking in manufacturing processes.

Performance and Efficiency Analysis

Mold release agents significantly enhance the efficiency of manufacturing by ensuring easy separation of molded parts, reducing cycle times and minimizing defects. Anti-block additives improve film clarity and processing by preventing adhesion between layers, enhancing material handling and product quality. Performance analysis reveals mold release excels in production speed and surface finish, while anti-block additives optimize film smoothness and stacking efficiency.

Impact on Product Quality

Mold release agents enhance product quality by ensuring smooth demolding, reducing surface defects, and preserving material integrity in manufacturing processes. Anti-block additives improve surface finish and clarity by preventing film layers from sticking together, thereby maintaining product appearance and functionality. Both contribute to higher quality end products by minimizing defects related to processing and handling.

Selection Criteria for Industrial Use

Selecting between mold release and anti-block agents for industrial use depends primarily on the application's surface interaction and end-product requirements. Mold release agents are essential for preventing adhesion between mold surfaces and materials like plastics or rubbers, ensuring smooth demolding and reducing cycle times. Your choice should consider factors such as material compatibility, processing temperature, and the desired finish, whereas anti-block agents are used mainly in film production to prevent layers from sticking together, improving handling and clarity.

Environmental and Safety Considerations

Mold release agents minimize environmental impact by reducing the need for harsh solvents and VOCs, making them safer for workers and compliant with environmental regulations. Anti-block additives enhance film recyclability by preventing surface adhesion without introducing toxic substances, thereby supporting sustainable packaging solutions. Both mold release and anti-block chemicals contribute to safer manufacturing processes by lowering exposure to hazardous compounds and promoting eco-friendly material handling.

Innovations in Mold Release and Anti-block Technologies

Innovations in mold release technologies have introduced advanced silicone-based formulations and fluoropolymer coatings that enhance release efficiency while reducing environmental impact. Anti-block technologies now utilize nano-scale additives and surface texturing methods to minimize film adhesion and improve processing speed. These advancements optimize manufacturing workflows, improve product quality, and support sustainability in packaging and molding applications.

Mold Release vs Anti-block Infographic

libmatt.com

libmatt.com