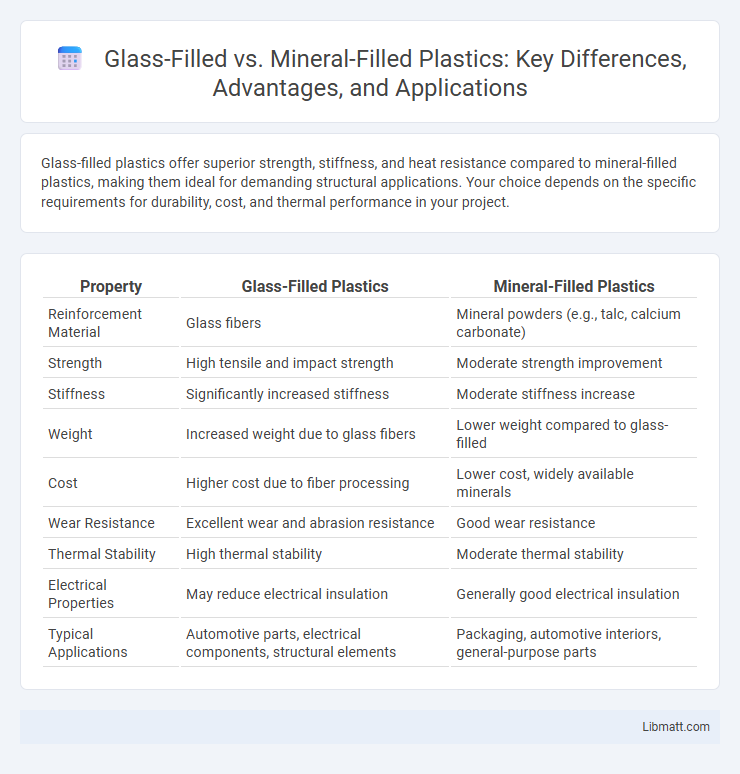

Glass-filled plastics offer superior strength, stiffness, and heat resistance compared to mineral-filled plastics, making them ideal for demanding structural applications. Your choice depends on the specific requirements for durability, cost, and thermal performance in your project.

Table of Comparison

| Property | Glass-Filled Plastics | Mineral-Filled Plastics |

|---|---|---|

| Reinforcement Material | Glass fibers | Mineral powders (e.g., talc, calcium carbonate) |

| Strength | High tensile and impact strength | Moderate strength improvement |

| Stiffness | Significantly increased stiffness | Moderate stiffness increase |

| Weight | Increased weight due to glass fibers | Lower weight compared to glass-filled |

| Cost | Higher cost due to fiber processing | Lower cost, widely available minerals |

| Wear Resistance | Excellent wear and abrasion resistance | Good wear resistance |

| Thermal Stability | High thermal stability | Moderate thermal stability |

| Electrical Properties | May reduce electrical insulation | Generally good electrical insulation |

| Typical Applications | Automotive parts, electrical components, structural elements | Packaging, automotive interiors, general-purpose parts |

Introduction to Filled Plastics

Filled plastics enhance mechanical properties by incorporating reinforcing materials like glass fibers or mineral fillers into the polymer matrix. Glass-filled plastics improve strength, stiffness, and heat resistance, making them ideal for automotive and industrial applications. Mineral-filled plastics primarily boost rigidity and dimensional stability while reducing cost, commonly used in consumer goods and electrical components.

Overview of Glass-Filled Plastics

Glass-filled plastics feature glass fibers embedded within a polymer matrix to enhance mechanical strength, stiffness, and thermal stability. Commonly used in automotive and aerospace industries, these composites offer superior impact resistance and dimensional stability compared to mineral-filled alternatives. The glass fiber content typically ranges from 10% to 40%, significantly improving tensile strength and reducing creep under load.

Overview of Mineral-Filled Plastics

Mineral-filled plastics incorporate inorganic minerals such as calcium carbonate, talc, or mica as fillers, enhancing rigidity, dimensional stability, and thermal resistance without significantly increasing weight. These fillers improve surface finish and reduce warpage, making mineral-filled plastics ideal for automotive components, electrical housings, and consumer goods requiring precision molding. Unlike glass-filled plastics, mineral fillers provide moderate reinforcement and cost-effective improvements while maintaining easier processing and reduced abrasion on tooling.

Key Composition Differences

Glass-filled plastics contain fine glass fibers embedded within the polymer matrix, significantly enhancing strength, stiffness, and thermal stability compared to mineral-filled plastics. Mineral-filled plastics incorporate inorganic additives like calcium carbonate or talc, which improve dimensional stability, surface finish, and reduce shrinkage but offer lower reinforcement than glass fibers. Understanding these key composition differences helps you select the optimal material for applications demanding either mechanical strength or cost-effective rigidity.

Mechanical Properties Comparison

Glass-filled plastics exhibit significantly higher tensile strength, stiffness, and impact resistance compared to mineral-filled plastics, making them ideal for load-bearing and structural applications. Mineral-filled plastics, while offering improved dimensional stability and reduced warpage, generally have lower mechanical strength and toughness than their glass-filled counterparts. Your choice depends on whether mechanical performance or processability takes precedence in the intended application.

Thermal Performance Analysis

Glass-filled plastics demonstrate superior thermal performance due to the high thermal conductivity and stability of glass fibers, which enhance heat resistance and dimensional stability under elevated temperatures. Mineral-filled plastics, incorporating minerals such as calcium carbonate or talc, provide improved thermal resistance by increasing the material's heat deflection temperature and reducing thermal expansion. Comparative studies show glass-filled composites excel in applications requiring sustained thermal endurance, while mineral-filled variants offer cost-effective solutions with moderate thermal improvement.

Processing and Manufacturability

Glass-filled plastics offer enhanced dimensional stability and strength during processing due to the incorporation of glass fibers, which improve mechanical properties and reduce warpage in molded parts. Mineral-filled plastics provide improved rigidity and hardness with better thermal stability but may lead to increased brittleness and wear on processing equipment. Both materials require specific processing adjustments, such as temperature control and mold design, to optimize manufacturability and achieve desired part performance.

Typical Applications and Industries

Glass-filled plastics are commonly used in automotive components, electrical housings, and industrial machinery due to their high strength, rigidity, and heat resistance. Mineral-filled plastics find applications in construction materials, consumer goods, and appliances, offering improved dimensional stability and enhanced thermal properties. Both materials are favored in industries requiring durable and lightweight solutions, with glass-filled plastics dominating performance-critical parts and mineral-filled plastics excelling in cost-sensitive, high-volume production.

Cost Considerations and Sustainability

Glass-filled plastics typically offer superior strength and durability but come at a higher cost compared to mineral-filled plastics, which are more budget-friendly due to lower raw material expenses. Mineral-filled plastics often provide enhanced sustainability benefits, including reduced energy consumption during production and increased recyclability, making them preferable for eco-conscious applications. Evaluating total lifecycle costs and environmental impact is crucial for selecting the optimal filler in plastics manufacturing.

Choosing the Right Filled Plastic

Selecting the right filled plastic hinges on the mechanical properties required, with glass-filled plastics offering superior strength, stiffness, and dimensional stability due to high glass fiber content. In contrast, mineral-filled plastics provide enhanced thermal conductivity, improved wear resistance, and cost-effectiveness by incorporating mineral additives like calcium carbonate or talc. Evaluating application-specific demands, such as load-bearing capacity or thermal management, ensures the optimal balance between performance and budget when choosing between glass-filled and mineral-filled plastics.

Glass-filled vs mineral-filled plastics Infographic

libmatt.com

libmatt.com